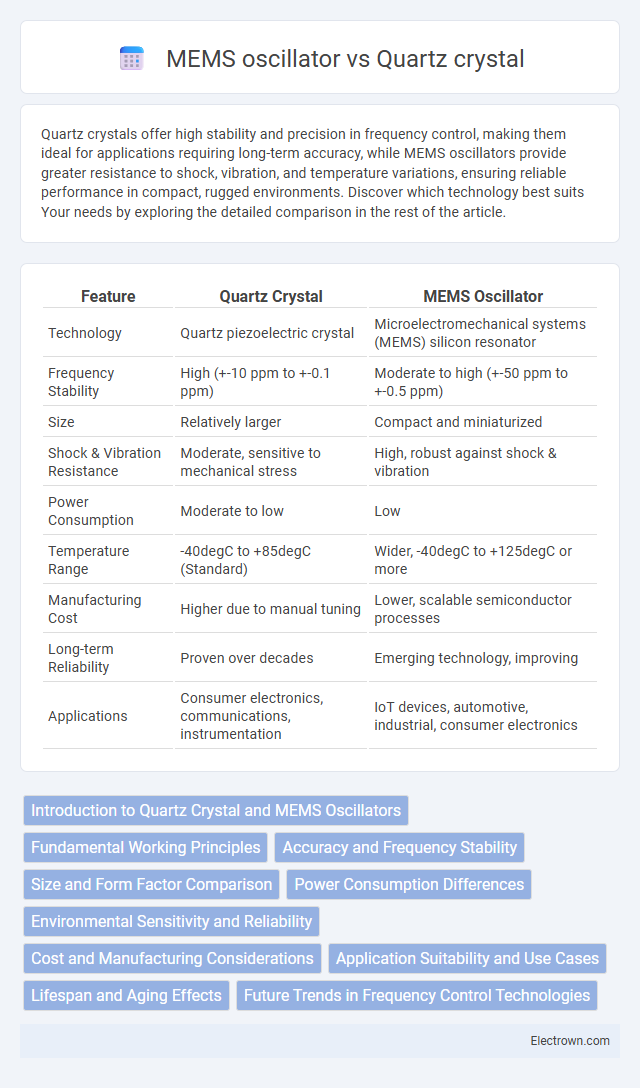

Quartz crystals offer high stability and precision in frequency control, making them ideal for applications requiring long-term accuracy, while MEMS oscillators provide greater resistance to shock, vibration, and temperature variations, ensuring reliable performance in compact, rugged environments. Discover which technology best suits Your needs by exploring the detailed comparison in the rest of the article.

Table of Comparison

| Feature | Quartz Crystal | MEMS Oscillator |

|---|---|---|

| Technology | Quartz piezoelectric crystal | Microelectromechanical systems (MEMS) silicon resonator |

| Frequency Stability | High (+-10 ppm to +-0.1 ppm) | Moderate to high (+-50 ppm to +-0.5 ppm) |

| Size | Relatively larger | Compact and miniaturized |

| Shock & Vibration Resistance | Moderate, sensitive to mechanical stress | High, robust against shock & vibration |

| Power Consumption | Moderate to low | Low |

| Temperature Range | -40degC to +85degC (Standard) | Wider, -40degC to +125degC or more |

| Manufacturing Cost | Higher due to manual tuning | Lower, scalable semiconductor processes |

| Long-term Reliability | Proven over decades | Emerging technology, improving |

| Applications | Consumer electronics, communications, instrumentation | IoT devices, automotive, industrial, consumer electronics |

Introduction to Quartz Crystal and MEMS Oscillators

Quartz crystal oscillators leverage the piezoelectric properties of quartz to generate highly stable frequencies commonly used in telecommunications, computers, and consumer electronics. MEMS oscillators employ microelectromechanical systems technology to produce precise timing signals with enhanced resistance to shock, vibration, and temperature variations, making them ideal for automotive and industrial applications. Both technologies serve critical roles in frequency control but differ in manufacturing processes, size, durability, and environmental tolerance.

Fundamental Working Principles

Quartz crystal oscillators utilize the piezoelectric effect of quartz, where mechanical vibrations generate precise electrical signals at a natural resonant frequency. MEMS oscillators employ microelectromechanical systems technology, using tiny cantilever beams or resonators vibrating at controlled frequencies to produce stable oscillations. Both technologies convert mechanical resonance into an electrical frequency reference, but quartz relies on bulk crystal properties while MEMS depends on microfabricated mechanical structures.

Accuracy and Frequency Stability

Quartz crystal oscillators provide exceptional frequency stability and accuracy due to their high Q-factor and inherent mechanical resonance, maintaining frequency variations typically within +-10 ppm over temperature ranges. MEMS oscillators offer competitive accuracy with frequency stability often within +-25 ppm, benefiting from integrated temperature compensation and improved shock resistance, making them suitable for compact and rugged applications. While quartz oscillators excel in ultra-high precision environments, MEMS oscillators are advancing rapidly and provide reliable frequency stability for many modern electronic devices.

Size and Form Factor Comparison

Quartz crystals typically have larger and bulkier form factors compared to MEMS oscillators, which benefit from advanced semiconductor fabrication techniques allowing for significantly smaller and thinner packages. MEMS oscillators often come in surface-mount packages as small as 2x1.2 mm or smaller, enabling compact designs for mobile and wearable devices where space is critical. The reduced size and integration capabilities of MEMS oscillators also facilitate lower system complexity and improved mechanical robustness versus the conventional quartz crystal form factors.

Power Consumption Differences

Quartz crystals consume significantly less power than MEMS oscillators, making them ideal for battery-powered and low-energy applications. MEMS oscillators typically require higher current due to their active circuitry, affecting overall device energy efficiency. Selecting quartz crystals is beneficial when minimizing power consumption is critical for long-term operation.

Environmental Sensitivity and Reliability

Quartz crystals exhibit high environmental sensitivity, as their frequency stability can be affected by temperature variations, mechanical shocks, and humidity, which may lead to drift or degradation over time. MEMS oscillators offer enhanced reliability with better immunity to environmental stresses, including vibration and extreme temperatures, due to their solid-state microfabrication and encapsulation techniques. This makes MEMS oscillators more suitable for harsh or variable environments where consistent performance is critical.

Cost and Manufacturing Considerations

Quartz crystal oscillators typically involve more complex manufacturing processes, resulting in higher production costs due to the need for precision cutting and tuning of quartz wafers. MEMS oscillators benefit from semiconductor fabrication techniques, enabling mass production with lower costs and improved scalability. The cost efficiency of MEMS oscillators becomes significant in high-volume applications where integration and miniaturization are critical.

Application Suitability and Use Cases

Quartz crystals are highly suitable for applications demanding ultra-stable frequency references, such as telecommunications, GPS systems, and high-precision measurement instruments due to their exceptional frequency accuracy and low phase noise. MEMS oscillators excel in environments requiring robust, compact, and low-power solutions, making them ideal for automotive electronics, consumer devices, and IoT applications where resistance to shock, vibration, and temperature variations is critical. The choice between quartz crystal and MEMS oscillator depends on specific application requirements for stability, size constraints, power efficiency, and environmental resilience.

Lifespan and Aging Effects

Quartz crystals typically offer a longer lifespan, often exceeding 20 years, with minimal frequency drift under stable environmental conditions. MEMS oscillators, while newer, provide greater resistance to shock and vibration but may experience faster aging effects, typically showing frequency shifts of a few ppm per year. Both technologies require careful consideration of application-specific reliability and aging characteristics to ensure optimal long-term performance.

Future Trends in Frequency Control Technologies

Quartz crystal oscillators have dominated frequency control due to their high stability and low phase noise, but MEMS oscillators are rapidly advancing with features like miniaturization, lower power consumption, and better integration capabilities for IoT and 5G devices. Emerging trends indicate MEMS technology will leverage CMOS compatibility for cost-effective mass production and offer enhanced environmental resilience, appealing to automotive and aerospace sectors. Innovations in temperature compensation methods and ultralow jitter performance are driving MEMS oscillators closer to quartz in precision, positioning them as the future standard for high-frequency control solutions.

quartz crystal vs MEMS oscillator Infographic

electrown.com

electrown.com