ENIG (Electroless Nickel Immersion Gold) and ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold) are advanced surface finish techniques commonly used in PCB manufacturing, where ENEPIG offers enhanced corrosion resistance and better solderability for complex assemblies compared to ENIG. Discover how these differences impact your PCB performance and which finish suits your specific application by reading the rest of this article.

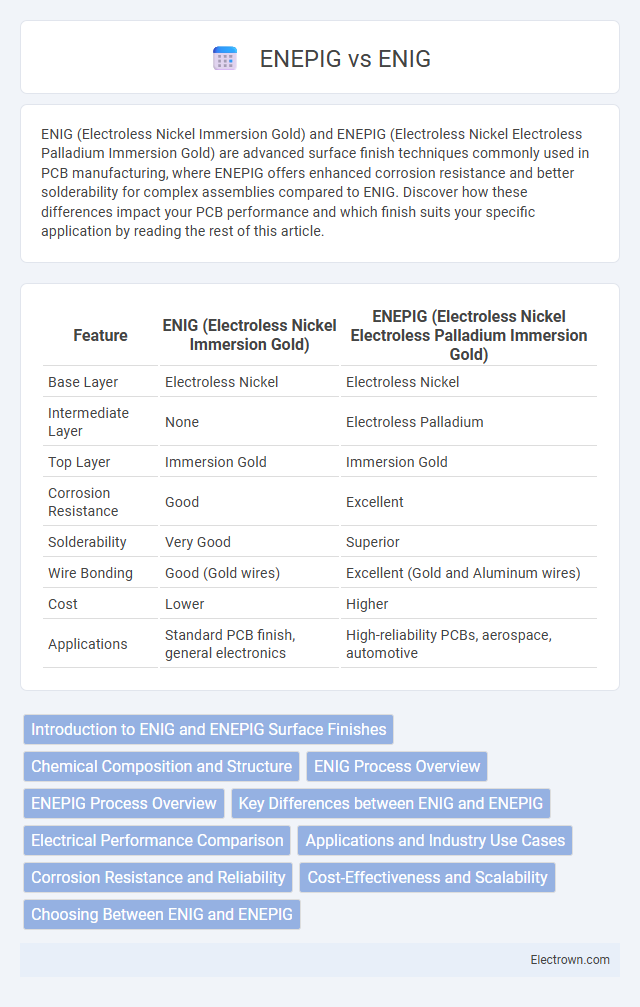

Table of Comparison

| Feature | ENIG (Electroless Nickel Immersion Gold) | ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold) |

|---|---|---|

| Base Layer | Electroless Nickel | Electroless Nickel |

| Intermediate Layer | None | Electroless Palladium |

| Top Layer | Immersion Gold | Immersion Gold |

| Corrosion Resistance | Good | Excellent |

| Solderability | Very Good | Superior |

| Wire Bonding | Good (Gold wires) | Excellent (Gold and Aluminum wires) |

| Cost | Lower | Higher |

| Applications | Standard PCB finish, general electronics | High-reliability PCBs, aerospace, automotive |

Introduction to ENIG and ENEPIG Surface Finishes

Electroless Nickel Immersion Gold (ENIG) and Electroless Nickel Electroless Palladium Immersion Gold (ENEPIG) are advanced surface finishes commonly used in printed circuit board (PCB) manufacturing. ENIG provides a thin layer of immersion gold over electroless nickel, offering excellent solderability and corrosion resistance, ideal for fine-pitch components. ENEPIG adds a palladium layer between the nickel and gold, enhancing wire bonding performance and preventing nickel corrosion, making it suitable for complex assemblies and high-reliability applications.

Chemical Composition and Structure

ENIG (Electroless Nickel Immersion Gold) features a chemical composition with a nickel-phosphorus base layer and a thin immersion gold layer, offering excellent conductivity and corrosion resistance. ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold) includes an additional palladium layer between the nickel and gold, enhancing oxidation resistance and solderability. Your choice between ENIG and ENEPIG influences surface finish reliability and performance based on the specific chemical structure requirements of your electronic components.

ENIG Process Overview

ENIG (Electroless Nickel Immersion Gold) involves depositing a thin layer of electroless nickel followed by an immersion gold layer, providing excellent surface planarity and solderability in PCB manufacturing. ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold) adds a palladium layer between the nickel and gold, enhancing corrosion resistance and wire bondability. The ENIG process is widely used for high-density interconnects due to its cost-effectiveness and reliable solder joint formation.

ENEPIG Process Overview

ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold) plating involves a multilayer deposition process starting with an electroless nickel layer that provides corrosion resistance and wear protection. This is followed by a thin electroless palladium layer acting as a barrier to prevent nickel diffusion, and finally, an immersion gold layer for excellent surface solderability and oxidation resistance. ENEPIG is widely used in advanced printed circuit boards (PCBs) to enhance solder joint reliability and electrical performance compared to the simpler ENIG (Electroless Nickel Immersion Gold) process.

Key Differences between ENIG and ENEPIG

ENIG (Electroless Nickel Immersion Gold) uses a nickel layer covered by a thin immersion gold coating, providing excellent solderability and corrosion resistance but limited wire bonding capabilities. ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold) adds a palladium layer between the nickel and gold, enhancing wire bonding performance and preventing nickel corrosion more effectively. ENEPIG's multi-metal layer offers superior oxidation resistance and is preferred for complex PCB applications requiring robust bonding and long-term reliability.

Electrical Performance Comparison

ENIG (Electroless Nickel Immersion Gold) and ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold) both enhance PCB surface finish conductivity, but ENEPIG delivers superior electrical performance due to its palladium layer that improves oxidation resistance and contact reliability. ENIG offers lower contact resistance suitable for fine pitch components, while ENEPIG excels in high-frequency applications with better signal integrity and corrosion resistance. ENEPIG's trilayer structure provides enhanced solderability and longer shelf life, making it ideal for advanced electronics requiring consistent electrical performance under harsh conditions.

Applications and Industry Use Cases

ENIG (Electroless Nickel Immersion Gold) and ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold) coatings serve critical roles in electronics manufacturing, with ENIG widely used for printed circuit boards (PCBs) in consumer electronics due to its excellent solderability and corrosion resistance. ENEPIG offers superior wire bonding capabilities, making it ideal for high-reliability applications in aerospace, automotive, and medical devices where enhanced surface hardness and longer shelf life are essential. Your choice between ENIG and ENEPIG should consider industry-specific requirements such as thermal stability and multiple reflow process compatibility.

Corrosion Resistance and Reliability

ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold) offers superior corrosion resistance compared to ENIG (Electroless Nickel Immersion Gold) due to the added palladium layer, which acts as a robust barrier against oxidation and sulfur contamination. This enhanced protective layer improves long-term reliability in harsh environmental conditions, reducing the risk of solder joint failures and oxidation-related defects. ENEPIG's multilayer structure ensures better surface stability and durability for high-performance electronic assemblies.

Cost-Effectiveness and Scalability

ENIG plating offers a more cost-effective solution for printed circuit boards due to lower material and process expenses compared to ENEPIG, which involves additional layers and precious metals. ENIG is highly scalable for mass production, making it suitable for large-volume manufacturing, while ENEPIG provides enhanced corrosion resistance and wire bondability but at a higher cost that limits its use to specialized applications. Your choice depends on balancing budget constraints with performance requirements in the PCB fabrication process.

Choosing Between ENIG and ENEPIG

ENIG (Electroless Nickel Immersion Gold) provides excellent corrosion resistance and flat surfaces ideal for wire bonding but may face challenges with solder joint reliability on certain components. ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold) adds a palladium layer enhancing solderability, preventing nickel corrosion, and supporting gold wire bonding and soldering in a wider range of applications. Selecting between ENIG and ENEPIG depends on requirements such as reliability in harsh environments, compatibility with mixed technologies, and cost considerations for multi-functional PCB assemblies.

ENIG vs ENEPIG Infographic

electrown.com

electrown.com