Kapton offers superior thermal stability and chemical resistance compared to Mylar, making it ideal for high-temperature applications. Explore the key differences and discover which material suits your project needs best in the rest of the article.

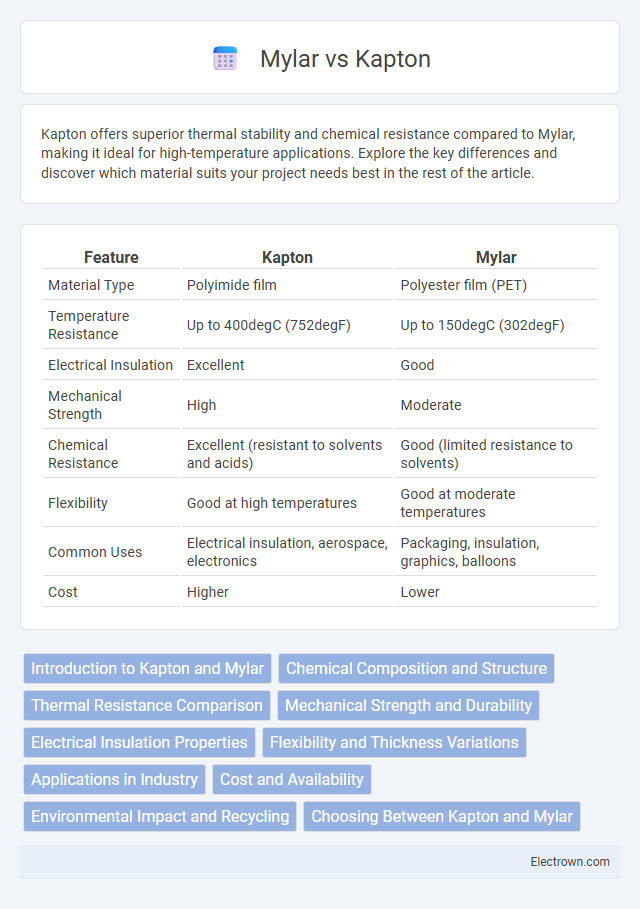

Table of Comparison

| Feature | Kapton | Mylar |

|---|---|---|

| Material Type | Polyimide film | Polyester film (PET) |

| Temperature Resistance | Up to 400degC (752degF) | Up to 150degC (302degF) |

| Electrical Insulation | Excellent | Good |

| Mechanical Strength | High | Moderate |

| Chemical Resistance | Excellent (resistant to solvents and acids) | Good (limited resistance to solvents) |

| Flexibility | Good at high temperatures | Good at moderate temperatures |

| Common Uses | Electrical insulation, aerospace, electronics | Packaging, insulation, graphics, balloons |

| Cost | Higher | Lower |

Introduction to Kapton and Mylar

Kapton is a polyimide film known for its exceptional thermal stability, electrical insulation, and chemical resistance, making it ideal for aerospace and electronics applications. Mylar, a polyester film made from polyethylene terephthalate (PET), offers strong tensile strength, flexibility, and resistance to moisture, widely used in packaging, insulation, and graphic arts. Both films serve distinct industrial roles due to their unique material properties and temperature tolerances.

Chemical Composition and Structure

Kapton is a polyimide film composed of aromatic polyimide chains, providing high thermal stability and excellent chemical resistance due to its rigid imide rings. Mylar, a polyester film made from polyethylene terephthalate (PET), features linear polymer chains with ester functional groups, offering strong mechanical strength and dimensional stability. The difference in chemical composition results in Kapton's superior performance in extreme temperatures, while Mylar excels in electrical insulation and moisture barrier properties.

Thermal Resistance Comparison

Kapton offers superior thermal resistance compared to Mylar, withstanding continuous temperatures up to 400degC, while Mylar typically endures up to 150degC. This makes Kapton ideal for applications requiring high-temperature durability, such as electronic insulation or aerospace components. Your choice between Kapton and Mylar should consider the specific thermal environment to ensure optimal performance and longevity.

Mechanical Strength and Durability

Kapton exhibits superior mechanical strength and durability due to its high tensile strength and excellent thermal stability, making it ideal for demanding environments. Mylar, while strong and flexible, generally has lower heat resistance and mechanical robustness compared to Kapton. Your choice should consider the long-term performance requirements, especially if exposure to extreme temperatures or harsh conditions is expected.

Electrical Insulation Properties

Kapton exhibits superior electrical insulation properties with a high dielectric strength of approximately 7 kV/mil and excellent thermal stability up to 400degC, making it ideal for high-performance electrical applications. Mylar, a form of polyester film, offers good insulation with a dielectric strength around 6.9 kV/mil but degrades at lower temperatures, limiting its use in high-heat environments. Both materials are widely used for electrical insulation, but Kapton's ability to maintain performance under extreme conditions distinguishes it in advanced electronics and aerospace industries.

Flexibility and Thickness Variations

Kapton offers superior flexibility and can maintain its mechanical properties across a wider temperature range compared to Mylar, making it ideal for applications requiring dynamic bending and thermal stability. Kapton films are available in thicknesses ranging from 7 microns to over 125 microns, while Mylar typically ranges from 12 microns to 250 microns, providing more options for diverse insulation and protective needs. The thinner Kapton variants excel in lightweight, space-constrained uses, whereas thicker Mylar films prioritize durability and dimensional stability.

Applications in Industry

Kapton films excel in high-temperature insulation for aerospace, electronics, and automotive industries due to their thermal stability up to 400degC and excellent electrical properties. Mylar, made of polyethylene terephthalate (PET), is widely used in packaging, insulation, and solar panel back-sheets because of its strength, transparency, and moisture resistance. Both materials serve critical roles in flexible electronics, thermal blankets, and protective coatings, with Kapton favored for extreme heat environments and Mylar preferred for cost-effective, durable barrier applications.

Cost and Availability

Kapton offers superior heat resistance and electrical insulation but comes at a higher cost and limited availability compared to Mylar. Mylar is more affordable and widely accessible, making it a preferred choice for budget-conscious applications. Both materials are commonly used in electronics and packaging, with Mylar being more prevalent due to its cost-effectiveness and broader distribution.

Environmental Impact and Recycling

Kapton and Mylar differ significantly in environmental impact and recyclability, with Mylar being more eco-friendly due to its polyester composition, which is easier to recycle in standard facilities. Kapton, made from polyimide, resists heat and chemicals but poses challenges for recycling because of its complex chemical structure and limited disposal options. You should consider Mylar for applications prioritizing sustainability and Kapton when performance outweighs environmental concerns.

Choosing Between Kapton and Mylar

Choosing between Kapton and Mylar depends on the specific application requirements, where Kapton excels with its high thermal stability up to 400degC and excellent electrical insulation properties. Mylar, a polyester film, offers strong tensile strength and resistance to moisture, making it ideal for packaging and insulation under moderate temperatures up to 150degC. Consider Kapton for aerospace, electronics, and high-temperature uses, while Mylar suits general-purpose insulation, packaging, and protective coverings.

Kapton vs Mylar Infographic

electrown.com

electrown.com