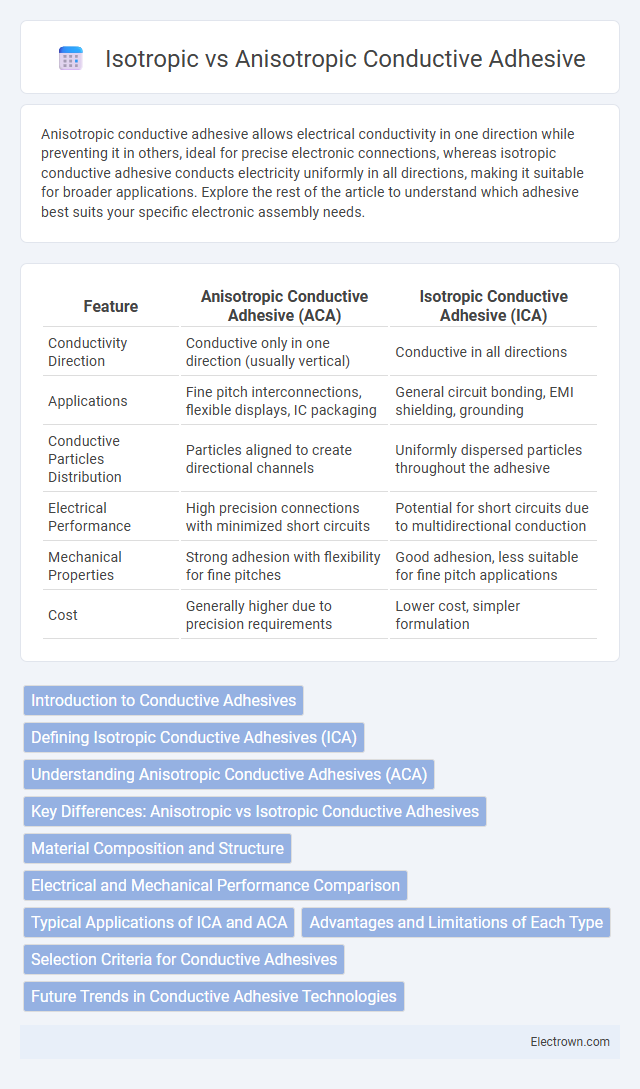

Anisotropic conductive adhesive allows electrical conductivity in one direction while preventing it in others, ideal for precise electronic connections, whereas isotropic conductive adhesive conducts electricity uniformly in all directions, making it suitable for broader applications. Explore the rest of the article to understand which adhesive best suits your specific electronic assembly needs.

Table of Comparison

| Feature | Anisotropic Conductive Adhesive (ACA) | Isotropic Conductive Adhesive (ICA) |

|---|---|---|

| Conductivity Direction | Conductive only in one direction (usually vertical) | Conductive in all directions |

| Applications | Fine pitch interconnections, flexible displays, IC packaging | General circuit bonding, EMI shielding, grounding |

| Conductive Particles Distribution | Particles aligned to create directional channels | Uniformly dispersed particles throughout the adhesive |

| Electrical Performance | High precision connections with minimized short circuits | Potential for short circuits due to multidirectional conduction |

| Mechanical Properties | Strong adhesion with flexibility for fine pitches | Good adhesion, less suitable for fine pitch applications |

| Cost | Generally higher due to precision requirements | Lower cost, simpler formulation |

Introduction to Conductive Adhesives

Conductive adhesives enable reliable electrical connections by combining adhesives with conductive particles, offering alternatives to traditional soldering. Anisotropic conductive adhesives (ACAs) allow conduction only in one direction, ideal for fine-pitch applications like LCD displays, while isotropic conductive adhesives (ICAs) conduct electricity uniformly in all directions, suitable for broader circuit bonding. Understanding the differences between ACA and ICA helps you select the optimal adhesive for your electronic assembly needs.

Defining Isotropic Conductive Adhesives (ICA)

Isotropic Conductive Adhesives (ICA) are advanced materials designed to provide electrical conductivity uniformly in all directions within an adhesive matrix. ICA typically consists of conductive fillers such as silver, carbon, or nickel particles dispersed evenly throughout a polymer resin, enabling consistent electrical pathways regardless of orientation. This omnidirectional conductivity makes ICA ideal for applications requiring robust electrical connections without directional constraints, such as in flexible electronics and circuit board assemblies.

Understanding Anisotropic Conductive Adhesives (ACA)

Anisotropic Conductive Adhesives (ACA) enable precise electrical connections by conducting current only in one direction, typically vertically between components, while preventing lateral conductivity. These adhesives contain uniformly dispersed conductive particles that create pathways under pressure, ensuring reliable connectivity without short circuits. Understanding ACA is essential for Your applications requiring fine-pitch interconnections, such as in flexible electronics and display assemblies.

Key Differences: Anisotropic vs Isotropic Conductive Adhesives

Anisotropic conductive adhesives (ACAs) allow electrical conduction primarily in one direction, typically vertical, ensuring precise connectivity while preventing short circuits between adjacent components. Isotropic conductive adhesives (ICAs) conduct electricity uniformly in all directions, providing flexibility in connections but increasing the risk of unintended electrical pathways. Key differences include directional conductivity, application methods, and suitability for fine-pitch electronics where ACAs excel due to controlled conduction paths.

Material Composition and Structure

Anisotropic conductive adhesives (ACAs) consist of resin matrices embedded with conductive particles aligned to allow electrical conductivity only in one direction, enhancing precision in circuit connections. Isotropic conductive adhesives (ICAs) use uniformly dispersed conductive fillers like silver flakes or carbon particles, ensuring multi-directional conductivity across the adhesive layer. Your choice depends on the specific application requirements for directional conductivity and mechanical performance in electronic assemblies.

Electrical and Mechanical Performance Comparison

Anisotropic conductive adhesives (ACAs) provide reliable electrical connectivity only in the z-axis, minimizing short circuits by preventing lateral conduction, while isotropic conductive adhesives (ICAs) conduct electricity uniformly in all directions, which can increase the risk of shorts but offer better mechanical flexibility. Mechanically, ACAs typically exhibit enhanced precision bonding with controlled conductivity, suitable for fine-pitch components, whereas ICAs deliver strong adhesion and durability under mechanical stress but may suffer from less controlled electrical pathways. The choice between ACA and ICA depends on the specific application requirements for conduction directionality, mechanical strength, and resistance to environmental factors.

Typical Applications of ICA and ACA

Isotropic conductive adhesives (ICAs) are widely used in applications requiring uniform electrical conductivity in all directions, such as attaching electronic components to flexible circuits and connecting display panels. Anisotropic conductive adhesives (ACAs) are preferred for fine-pitch interconnections in LCD and OLED displays, providing vertical conductivity while preventing lateral short circuits. Both ICAs and ACAs enable reliable electrical and mechanical bonding in electronic packaging, with ICAs suited for board-level mounting and ACAs optimized for precise alignment in high-density semiconductor devices.

Advantages and Limitations of Each Type

Anisotropic conductive adhesives offer precise electrical connections by enabling conductivity only along specific directions, which minimizes short circuits and suits high-density electronics but may require more complex processing and higher costs. Isotropic conductive adhesives provide uniform conductivity in all directions, simplifying application and reducing cost but increase the risk of electrical shorts in fine-pitch circuits and generally exhibit lower mechanical strength. The choice depends on application needs such as circuit complexity, reliability requirements, and manufacturing constraints.

Selection Criteria for Conductive Adhesives

When selecting between anisotropic and isotropic conductive adhesives, consider the electrical connectivity requirements and circuit density of your application. Anisotropic conductive adhesive (ACA) provides vertical conductivity while preventing lateral short circuits, ideal for fine-pitch connections and flexible electronics. Isotropic conductive adhesive (ICA) offers conductivity in all directions, suitable for general bonding needs where uniform conductivity and mechanical strength are essential for your electronic assemblies.

Future Trends in Conductive Adhesive Technologies

Future trends in conductive adhesive technologies emphasize enhanced performance and miniaturization, with anisotropic conductive adhesives (ACAs) gaining prominence for precise electrical connections in high-density electronics. Innovations in isotropic conductive adhesives (ICAs) aim to improve thermal stability and conductivity, addressing demands in flexible and wearable devices. Your choice between ACA and ICA will increasingly depend on application-specific requirements, including mechanical flexibility and electrical reliability.

anisotropic vs isotropic conductive adhesive Infographic

electrown.com

electrown.com