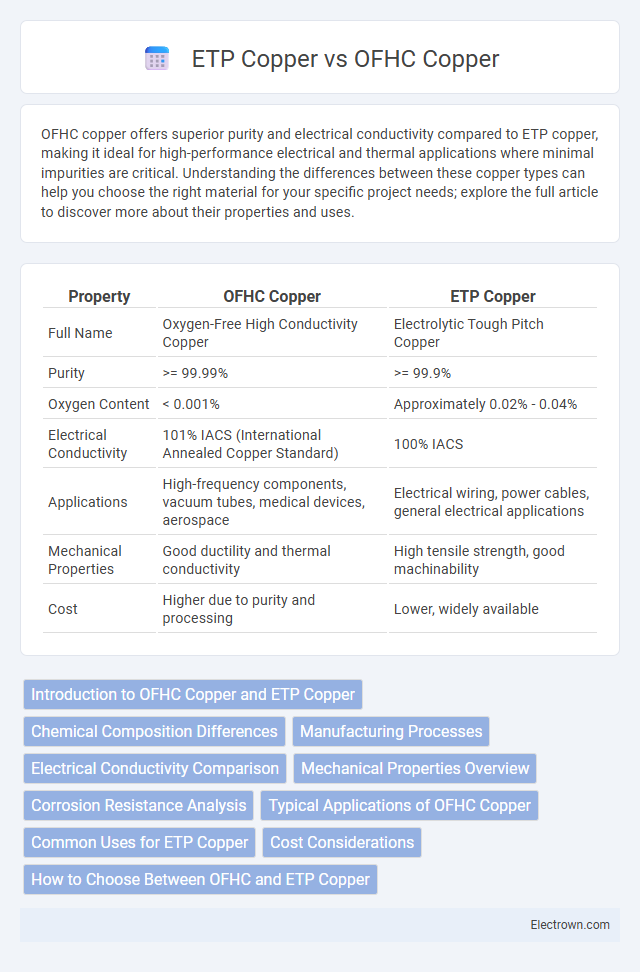

OFHC copper offers superior purity and electrical conductivity compared to ETP copper, making it ideal for high-performance electrical and thermal applications where minimal impurities are critical. Understanding the differences between these copper types can help you choose the right material for your specific project needs; explore the full article to discover more about their properties and uses.

Table of Comparison

| Property | OFHC Copper | ETP Copper |

|---|---|---|

| Full Name | Oxygen-Free High Conductivity Copper | Electrolytic Tough Pitch Copper |

| Purity | >= 99.99% | >= 99.9% |

| Oxygen Content | < 0.001% | Approximately 0.02% - 0.04% |

| Electrical Conductivity | 101% IACS (International Annealed Copper Standard) | 100% IACS |

| Applications | High-frequency components, vacuum tubes, medical devices, aerospace | Electrical wiring, power cables, general electrical applications |

| Mechanical Properties | Good ductility and thermal conductivity | High tensile strength, good machinability |

| Cost | Higher due to purity and processing | Lower, widely available |

Introduction to OFHC Copper and ETP Copper

OFHC copper (Oxygen-Free High Conductivity) and ETP copper (Electrolytic Tough Pitch) are two widely used copper grades distinguished by purity and conductivity. OFHC copper contains at least 99.99% copper with minimal oxygen content, offering superior electrical and thermal conductivity ideal for high-performance electronic components. ETP copper, with about 99.9% purity and slightly higher oxygen levels, balances excellent conductivity with cost-effectiveness, making it common in electrical wiring and industrial applications.

Chemical Composition Differences

OFHC copper, or Oxygen-Free High Conductivity copper, boasts a purity level of at least 99.99% copper with oxygen content below 0.001%, ensuring superior electrical and thermal conductivity. ETP copper, or Electrolytic Tough Pitch copper, contains approximately 99.9% copper but includes oxygen content ranging from 0.02% to 0.04%, which can form copper oxides affecting its conductivity. The reduced oxygen in OFHC copper minimizes oxide inclusions, leading to enhanced mechanical properties and reliability in high-performance electrical applications compared to ETP copper.

Manufacturing Processes

OFHC copper undergoes a high-purity refining process involving electrorefining and vacuum melting to achieve 99.99% copper content, removing oxygen and impurities for superior electrical and thermal conductivity. ETP copper is produced through electro-refining but retains a higher oxygen content, typically around 0.02%, which can affect its ductility and corrosion resistance. The manufacturing techniques of OFHC copper emphasize strict control of contamination and oxygen levels, making it ideal for high-performance applications in electronics and vacuum systems.

Electrical Conductivity Comparison

OFHC copper exhibits electrical conductivity of approximately 101% IACS (International Annealed Copper Standard), surpassing ETP copper, which typically measures around 100% IACS. The higher purity of OFHC copper, with oxygen content below 0.0005%, significantly reduces electron scattering, resulting in superior conductivity. In high-performance electrical applications, OFHC copper's enhanced conductivity ensures better efficiency and reduced energy losses compared to ETP copper.

Mechanical Properties Overview

OFHC copper exhibits superior mechanical properties compared to ETP copper, featuring higher purity levels above 99.99% that enhance ductility, electrical conductivity, and corrosion resistance. ETP copper, with its slightly lower purity of around 99.90% and trace oxygen content, tends to have greater strength but reduced thermal and electrical conductivity. The refined microstructure of OFHC copper results in improved tensile strength and better performance under thermal cycling, making it ideal for critical electrical and vacuum applications.

Corrosion Resistance Analysis

OFHC copper exhibits superior corrosion resistance compared to ETP copper due to its high purity level of 99.99% copper content, which minimizes impurities that typically accelerate corrosion processes. ETP copper contains trace elements like oxygen and other impurities that can lead to faster oxidation and reduced durability in harsh environments. Your choice of copper for applications requiring long-term corrosion resistance should prioritize OFHC copper for enhanced performance and longevity.

Typical Applications of OFHC Copper

OFHC copper is widely used in high-performance electrical and electronic components due to its exceptional purity and superior conductivity, making it ideal for vacuum systems, semiconductor fabrication, and cryogenic applications. Unlike ETP copper, which is commonly found in general electrical wiring and plumbing, OFHC copper excels in environments requiring minimal contamination and enhanced thermal and electrical properties. Your choice of OFHC copper ensures optimal reliability in sensitive industrial, medical, and scientific equipment where purity and conductivity are critical.

Common Uses for ETP Copper

ETP copper, or Electrolytic Tough Pitch copper, is widely used for electrical wiring, busbars, and transformers due to its excellent electrical conductivity and cost-effectiveness. In contrast to OFHC copper, which is preferred for high-purity applications, ETP copper finds common use in general electrical and thermal conductors. Your choice of copper should consider these typical uses to balance performance and budget.

Cost Considerations

OFHC copper typically costs more than ETP copper due to its higher purity and superior conductivity, making it ideal for high-performance applications. ETP copper offers a more budget-friendly option with acceptable conductivity for general electrical uses, balancing cost and performance effectively. Your choice depends on whether the application requires premium copper quality or prioritizes cost-efficiency.

How to Choose Between OFHC and ETP Copper

Choosing between OFHC (Oxygen-Free High Conductivity) copper and ETP (Electrolytic Tough Pitch) copper depends on electrical and thermal conductivity requirements, purity levels, and application environments. OFHC copper, with a purity of 99.99% or higher, offers superior conductivity and corrosion resistance, making it ideal for high-performance electrical components, vacuum systems, and cryogenic applications. ETP copper, containing about 99.9% purity with minimal oxygen content, is cost-effective and suitable for general electrical wiring, busbars, and grounding, where moderate conductivity and mechanical strength are sufficient.

OFHC copper vs ETP copper Infographic

electrown.com

electrown.com