ENIG surface finish offers excellent corrosion resistance and flatness, making it ideal for fine-pitch components, while Immersion Silver provides superior solderability and electrical conductivity with a smooth surface finish. Explore the full article to understand which surface finish suits Your specific PCB manufacturing needs best.

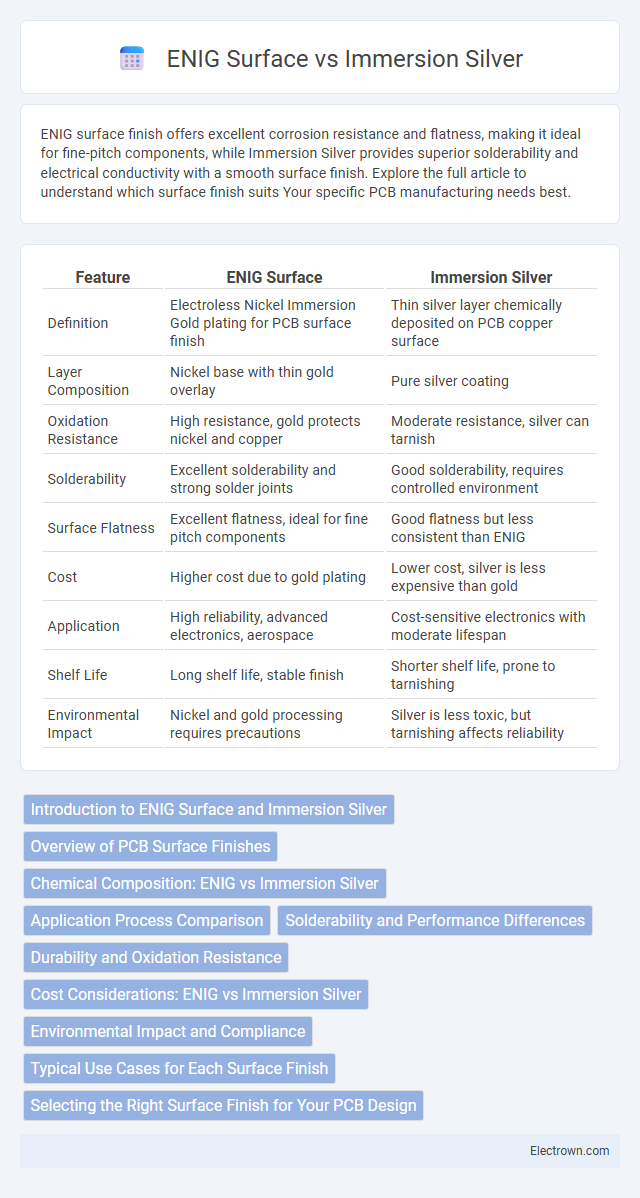

Table of Comparison

| Feature | ENIG Surface | Immersion Silver |

|---|---|---|

| Definition | Electroless Nickel Immersion Gold plating for PCB surface finish | Thin silver layer chemically deposited on PCB copper surface |

| Layer Composition | Nickel base with thin gold overlay | Pure silver coating |

| Oxidation Resistance | High resistance, gold protects nickel and copper | Moderate resistance, silver can tarnish |

| Solderability | Excellent solderability and strong solder joints | Good solderability, requires controlled environment |

| Surface Flatness | Excellent flatness, ideal for fine pitch components | Good flatness but less consistent than ENIG |

| Cost | Higher cost due to gold plating | Lower cost, silver is less expensive than gold |

| Application | High reliability, advanced electronics, aerospace | Cost-sensitive electronics with moderate lifespan |

| Shelf Life | Long shelf life, stable finish | Shorter shelf life, prone to tarnishing |

| Environmental Impact | Nickel and gold processing requires precautions | Silver is less toxic, but tarnishing affects reliability |

Introduction to ENIG Surface and Immersion Silver

ENIG surface, or Electroless Nickel Immersion Gold, provides a robust PCB finish with excellent solderability and corrosion resistance, combining a layer of nickel topped with a thin gold coating. Immersion silver offers a cost-effective, environmentally friendly alternative, featuring a silver layer that ensures good electrical conductivity and surface planarity ideal for fine-pitch components. You can choose between ENIG for enhanced durability and high-reliability applications or Immersion Silver for superior signal integrity and affordability.

Overview of PCB Surface Finishes

ENIG (Electroless Nickel Immersion Gold) and Immersion Silver are both popular PCB surface finishes offering reliable solderability and corrosion protection. ENIG provides excellent flatness, superior oxidation resistance, and long shelf life due to its nickel gold plating, making it ideal for fine-pitch components and multiple reflows. Immersion Silver offers a cost-effective, environmentally friendly option with good conductivity and is suited for applications requiring short to medium shelf life and reliable electrical performance.

Chemical Composition: ENIG vs Immersion Silver

ENIG (Electroless Nickel Immersion Gold) consists of a nickel-phosphorus alloy layer topped with a thin gold layer, providing excellent solderability and corrosion resistance. Immersion silver (ImAg) involves depositing a thin layer of pure silver onto the copper surface, enhancing electrical conductivity and protecting against oxidation. ENIG offers superior chemical stability due to the nickel barrier, while immersion silver is more prone to tarnishing but delivers better planarity for fine-pitch applications.

Application Process Comparison

ENIG surface finish involves a two-step process of electroless nickel plating followed by immersion gold, providing excellent solderability and corrosion resistance, while Immersion Silver is a single-step chemical deposition process that offers a thin, highly conductive silver layer ideal for high-frequency applications. ENIG requires precise control of plating thickness to avoid issues such as nickel oxidation, whereas Immersion Silver demands strict environmental control during deposition to prevent silver tarnishing. Your choice depends on the desired durability, conductivity, and substrate compatibility for your PCB application.

Solderability and Performance Differences

ENIG surface finish offers excellent solderability with a flat, nickel-gold layer that provides superior corrosion resistance and long shelf life, making it ideal for fine-pitch components. Immersion silver delivers good solderability characterized by a thin, conductive silver layer that supports high electrical performance but is more prone to oxidation and requires careful handling. Your choice between ENIG and Immersion silver depends on the specific performance needs, such as durability and signal integrity, with ENIG favored for robustness and Immersion silver for cost-effective, high-frequency applications.

Durability and Oxidation Resistance

ENIG (Electroless Nickel Immersion Gold) offers superior durability and oxidation resistance due to its nickel layer, which prevents oxidation and enhances surface hardness, making it ideal for multiple soldering cycles. Immersion silver, while providing excellent initial solderability with low contact resistance, is more prone to tarnishing and oxidation over time, especially in harsh or humid environments. For long-term reliability in PCB applications, ENIG outperforms immersion silver by maintaining surface integrity and preventing signal degradation caused by corrosion.

Cost Considerations: ENIG vs Immersion Silver

ENIG (Electroless Nickel Immersion Gold) typically incurs higher costs due to the use of precious metals like gold and complex deposition processes compared to Immersion Silver, which uses less expensive silver and simpler application methods. ENIG offers superior surface durability and oxidation resistance, justifying its premium price for high-reliability electronics, whereas Immersion Silver is favored for cost-sensitive applications with moderate shelf life requirements. Budget constraints and application-specific demands are key factors in choosing between ENIG and Immersion Silver finishes.

Environmental Impact and Compliance

ENIG surface finish uses gold and nickel layers that require strict control of heavy metals, making its disposal and recycling more complex under environmental regulations like RoHS and WEEE. Immersion silver offers a more environmentally friendly alternative with lower heavy metal content and easier compliance with global environmental standards due to its non-toxic silver coating. Your choice between ENIG and Immersion silver can significantly influence your product's environmental footprint and regulatory adherence.

Typical Use Cases for Each Surface Finish

ENIG (Electroless Nickel Immersion Gold) surface finish is typically used in high-reliability applications such as aerospace, medical devices, and high-performance electronics due to its excellent oxidation resistance and solderability. Immersion silver is preferred for cost-sensitive consumer electronics and high-frequency applications, offering good surface planarity and solder joint integrity. Both finishes are essential in PCB manufacturing, with ENIG favored for multi-layer boards requiring fine pitch components and immersion silver for rapid prototyping and RF circuitry.

Selecting the Right Surface Finish for Your PCB Design

Selecting the right surface finish for your PCB design involves evaluating key factors such as solderability, cost, and environmental impact. ENIG (Electroless Nickel Immersion Gold) offers excellent planarity and long shelf life, making it ideal for fine-pitch components and multiple reflows. Immersion silver provides superior electrical performance and cost efficiency but requires careful handling due to susceptibility to tarnishing and limited storage time.

ENIG surface vs Immersion silver Infographic

electrown.com

electrown.com