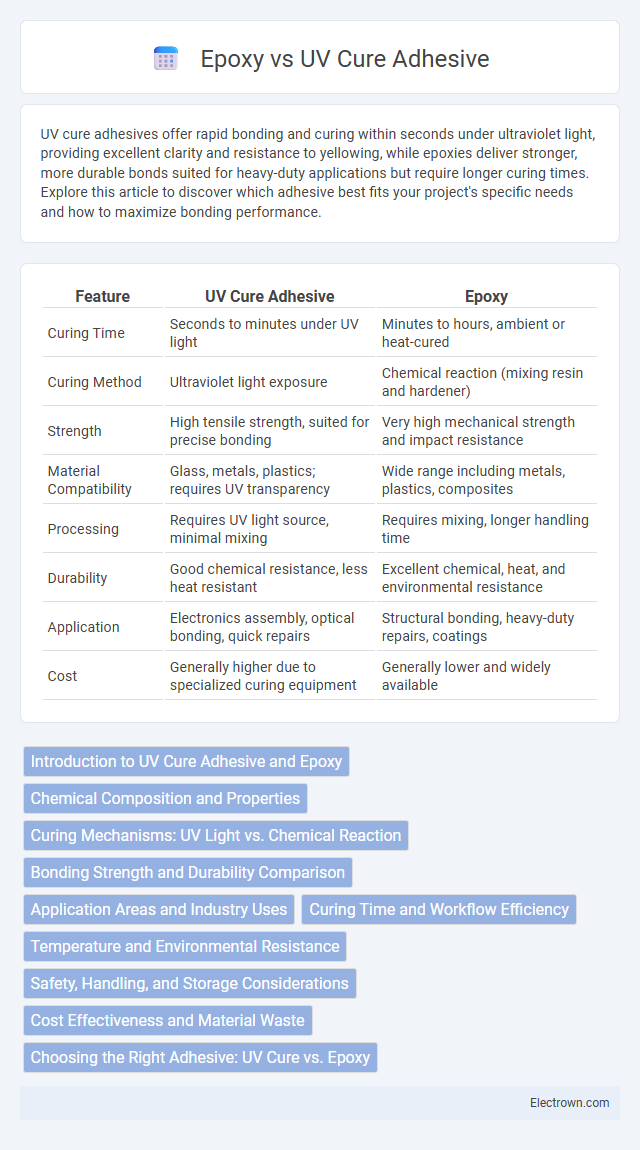

UV cure adhesives offer rapid bonding and curing within seconds under ultraviolet light, providing excellent clarity and resistance to yellowing, while epoxies deliver stronger, more durable bonds suited for heavy-duty applications but require longer curing times. Explore this article to discover which adhesive best fits your project's specific needs and how to maximize bonding performance.

Table of Comparison

| Feature | UV Cure Adhesive | Epoxy |

|---|---|---|

| Curing Time | Seconds to minutes under UV light | Minutes to hours, ambient or heat-cured |

| Curing Method | Ultraviolet light exposure | Chemical reaction (mixing resin and hardener) |

| Strength | High tensile strength, suited for precise bonding | Very high mechanical strength and impact resistance |

| Material Compatibility | Glass, metals, plastics; requires UV transparency | Wide range including metals, plastics, composites |

| Processing | Requires UV light source, minimal mixing | Requires mixing, longer handling time |

| Durability | Good chemical resistance, less heat resistant | Excellent chemical, heat, and environmental resistance |

| Application | Electronics assembly, optical bonding, quick repairs | Structural bonding, heavy-duty repairs, coatings |

| Cost | Generally higher due to specialized curing equipment | Generally lower and widely available |

Introduction to UV Cure Adhesive and Epoxy

UV cure adhesives harden rapidly when exposed to ultraviolet light, offering fast curing times and precise bonding ideal for electronics and medical devices. Epoxy adhesives provide strong, durable bonds through chemical curing, excelling in structural applications requiring high strength and chemical resistance. Your choice depends on the need for quick assembly with light-activated curing or robust, versatile bonding with extended working time.

Chemical Composition and Properties

UV cure adhesives consist primarily of acrylate monomers and photoinitiators that harden rapidly when exposed to ultraviolet light, offering fast curing and strong bonding with excellent clarity. Epoxy adhesives are based on epoxy resins and hardeners, providing superior chemical resistance, mechanical strength, and thermal stability but requiring longer curing times and sometimes heat activation. Your choice depends on application needs; UV cure adhesives excel in speed and transparency, while epoxies perform better under harsh environmental conditions.

Curing Mechanisms: UV Light vs. Chemical Reaction

UV cure adhesives rely on ultraviolet light to initiate a photochemical reaction that rapidly hardens the adhesive upon exposure, enabling precise control over curing time and location. Epoxy adhesives undergo a chemical reaction between resin and hardener components, resulting in a cross-linked polymer network through a curing process that often requires heat or extended time. Understanding these distinct curing mechanisms helps you select the optimal adhesive for applications demanding fast curing or strong, durable bonds.

Bonding Strength and Durability Comparison

UV cure adhesives offer rapid curing times and strong initial bonding strength, making them ideal for applications requiring fast processing and clear, precise bonds. Epoxy adhesives provide superior long-term durability and higher resistance to chemicals, temperature extremes, and mechanical stress, ensuring more robust performance in demanding environments. Your choice depends on whether immediate adhesion speed or enduring strength under harsh conditions is the priority for your project.

Application Areas and Industry Uses

UV cure adhesives excel in electronics manufacturing for bonding small components due to their rapid curing under ultraviolet light, making them ideal for assembling smartphones and medical devices. Epoxy adhesives are widely used in automotive and aerospace industries where high mechanical strength and chemical resistance are critical for structural bonding and composite repairs. Both adhesives find applications in construction, but UV cures offer faster processing while epoxies provide superior durability in harsh environmental conditions.

Curing Time and Workflow Efficiency

UV cure adhesives typically achieve full strength within seconds to minutes when exposed to the appropriate UV light wavelength, significantly reducing curing time compared to epoxy adhesives, which often require several hours to cure at room temperature or accelerated heat conditions. This rapid curing process enhances workflow efficiency by allowing immediate handling and assembly, minimizing production bottlenecks. Conversely, epoxy adhesives offer longer working times and stronger bonds in certain applications but generally slow down manufacturing cycles due to extended cure times.

Temperature and Environmental Resistance

UV cure adhesives exhibit excellent temperature resistance up to 150degC, making them suitable for applications requiring fast curing under controlled conditions but show limited performance under prolonged high-temperature exposure compared to epoxy. Epoxy adhesives offer superior thermal stability, withstanding temperatures up to 250degC and maintaining strength in harsh environmental conditions such as moisture, chemicals, and UV exposure. The choice between UV cure adhesives and epoxies depends on the required operating temperature range and environmental factors, with epoxies being preferred for demanding durability and resistance applications.

Safety, Handling, and Storage Considerations

UV cure adhesives offer enhanced safety with minimal hazardous emissions and rapid curing under controlled light exposure, reducing prolonged chemical handling risks. Epoxy resins demand careful handling due to potential skin sensitization, volatile organic compounds (VOCs), and longer curing times that increase exposure. Storage of UV adhesives requires protection from ambient light to prevent premature curing, while epoxies need temperature-stable environments to maintain shelf life and avoid viscosity changes.

Cost Effectiveness and Material Waste

UV cure adhesives offer superior cost effectiveness compared to epoxy due to their rapid curing times, which significantly reduce labor costs and improve production efficiency. These adhesives minimize material waste since they only cure upon exposure to UV light, allowing precise application and less excess use. Your manufacturing process benefits from lower disposal costs and higher yield rates by choosing UV cure adhesives over traditional epoxies.

Choosing the Right Adhesive: UV Cure vs. Epoxy

Selecting the right adhesive depends on your project's requirements for curing time and bond strength; UV cure adhesives offer rapid curing under ultraviolet light, making them ideal for quick assembly and transparent materials. Epoxy adhesives provide superior mechanical strength and chemical resistance, suitable for heavy-duty applications and bonding diverse substrates. Understanding your priorities in speed, durability, and material compatibility will help you choose between UV cure adhesives and epoxy for optimal results.

UV cure adhesive vs epoxy Infographic

electrown.com

electrown.com