ITO (Indium Tin Oxide) and FTO (Fluorine-doped Tin Oxide) are widely used transparent conductive oxides with distinct electrical conductivity and optical transparency suited for applications in displays and solar cells. Understanding the differences in properties and cost-efficiency between ITO and FTO will help you choose the best material for your specific needs; continue reading to explore their detailed comparisons.

Table of Comparison

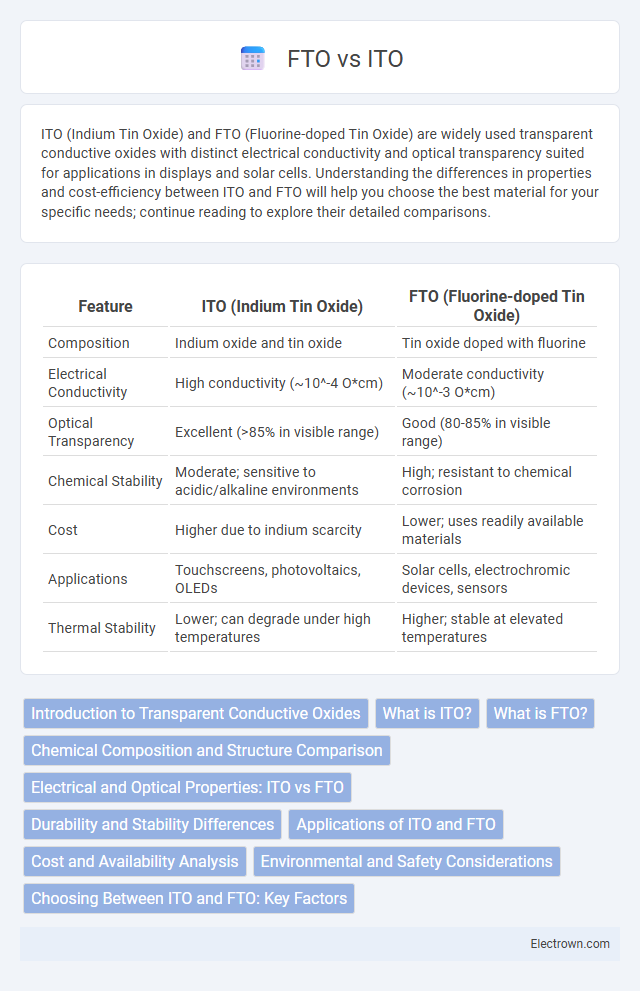

| Feature | ITO (Indium Tin Oxide) | FTO (Fluorine-doped Tin Oxide) |

|---|---|---|

| Composition | Indium oxide and tin oxide | Tin oxide doped with fluorine |

| Electrical Conductivity | High conductivity (~10^-4 O*cm) | Moderate conductivity (~10^-3 O*cm) |

| Optical Transparency | Excellent (>85% in visible range) | Good (80-85% in visible range) |

| Chemical Stability | Moderate; sensitive to acidic/alkaline environments | High; resistant to chemical corrosion |

| Cost | Higher due to indium scarcity | Lower; uses readily available materials |

| Applications | Touchscreens, photovoltaics, OLEDs | Solar cells, electrochromic devices, sensors |

| Thermal Stability | Lower; can degrade under high temperatures | Higher; stable at elevated temperatures |

Introduction to Transparent Conductive Oxides

Transparent Conductive Oxides (TCOs) such as Indium Tin Oxide (ITO) and Fluorine-doped Tin Oxide (FTO) are essential materials in optoelectronic devices due to their unique combination of high electrical conductivity and optical transparency. ITO offers superior electrical conductivity and excellent optical clarity, making it a preferred choice for touchscreens and OLEDs, while FTO provides enhanced chemical stability and durability, often used in solar cells and electrochromic windows. Understanding the specific properties of ITO and FTO helps you select the most suitable TCO for your application's performance and environmental requirements.

What is ITO?

ITO, or Indium Tin Oxide, is a transparent conducting oxide widely used in touchscreens, LCDs, and solar cells due to its excellent electrical conductivity and optical transparency. This material consists of indium oxide mixed with tin oxide, providing a balance between transparency and conductivity essential for electronic display technologies. Your devices benefit from ITO's ability to maintain clear visuals while enabling effective electrical performance.

What is FTO?

Freedom to Operate (FTO) is a legal assessment that determines whether a product or process infringes existing patents or intellectual property rights in a specific market. This evaluation helps companies avoid costly litigation by identifying potential patent obstacles before product development or commercialization. FTO analyses are essential for strategic planning, ensuring innovation can be safely marketed without violating third-party patents.

Chemical Composition and Structure Comparison

ITO (Indium Tin Oxide) consists primarily of indium oxide (In2O3) doped with tin oxide (SnO2), typically around 90% In2O3 and 10% SnO2, forming a crystalline structure that offers excellent electrical conductivity and optical transparency. FTO (Fluorine-doped Tin Oxide) is composed mainly of tin oxide (SnO2) doped with fluorine, which replaces some oxygen atoms in the lattice, enhancing conductivity while maintaining a stable tetragonal rutile structure. Your choice between ITO and FTO depends on the required balance between conductivity, transparency, and chemical stability, as ITO provides higher transparency but is less chemically robust compared to the more durable FTO.

Electrical and Optical Properties: ITO vs FTO

Indium Tin Oxide (ITO) offers superior electrical conductivity and higher optical transparency in the visible range compared to Fluorine-doped Tin Oxide (FTO), making it ideal for applications requiring efficient light transmission and low resistivity. FTO, while slightly less conductive and transparent, exhibits greater chemical and thermal stability, which is advantageous in harsh environmental conditions and high-temperature processes. The choice between ITO and FTO depends on the balance of conductivity, transparency, and stability required for specific optoelectronic devices such as solar cells, touchscreens, or LCD displays.

Durability and Stability Differences

ITO offers excellent durability and optical transparency but is brittle and prone to cracking under stress, affecting long-term stability in flexible applications. FTO provides superior chemical and thermal stability, maintaining conductivity and structural integrity at higher temperatures and in harsh environments. Your choice between ITO and FTO should consider the required mechanical flexibility and operational conditions to ensure optimal performance.

Applications of ITO and FTO

ITO (Indium Tin Oxide) is widely used in touchscreens, flat-panel displays, and solar cells due to its excellent electrical conductivity and optical transparency. FTO (Fluorine-doped Tin Oxide) is commonly applied in photovoltaic devices, electrochromic windows, and gas sensors because of its thermal stability and chemical resistance. Your choice between ITO and FTO depends on the specific requirements of transparency, conductivity, and environmental durability in your application.

Cost and Availability Analysis

ITO (Indium Tin Oxide) typically incurs higher costs due to the scarcity of indium and complex sputtering deposition methods, while FTO (Fluorine-doped Tin Oxide) offers a more cost-effective alternative leveraging abundant tin resources and simpler fabrication techniques. Availability of ITO is constrained by limited indium supplies and increasing demand in touchscreens and photovoltaics, whereas FTO benefits from widespread tin deposits ensuring steady production and lower price volatility. Cost-efficiency and material abundance position FTO as a favorable choice for large-scale applications requiring transparent conductive oxides.

Environmental and Safety Considerations

Indium Tin Oxide (ITO) and Fluorine-doped Tin Oxide (FTO) differ significantly in environmental and safety aspects; ITO production involves indium, a scarce resource with potential supply risks and toxicological concerns during handling. FTO uses fluorine and tin, which generally present lower toxicity and are more abundant, making FTO a safer and more sustainable option for large-scale manufacturing. Your choice between ITO and FTO should consider these factors to minimize environmental impact and enhance workplace safety.

Choosing Between ITO and FTO: Key Factors

Choosing between Indium Tin Oxide (ITO) and Fluorine-doped Tin Oxide (FTO) depends on factors like electrical conductivity, transparency, and cost-effectiveness. ITO offers higher optical clarity and conductivity, making it ideal for touchscreens and displays, while FTO provides better chemical stability and is preferred in solar cells and electrochemical devices. Evaluating Your application's environmental conditions and performance requirements is crucial to selecting the optimal transparent conductive oxide.

ITO vs FTO Infographic

electrown.com

electrown.com