Lead-free solder offers a safer, environmentally friendly alternative by eliminating toxic lead, but it typically requires higher temperatures and may have different mechanical properties compared to leaded solder. Discover how these differences impact your electronics projects and the best choice for your application in the full article.

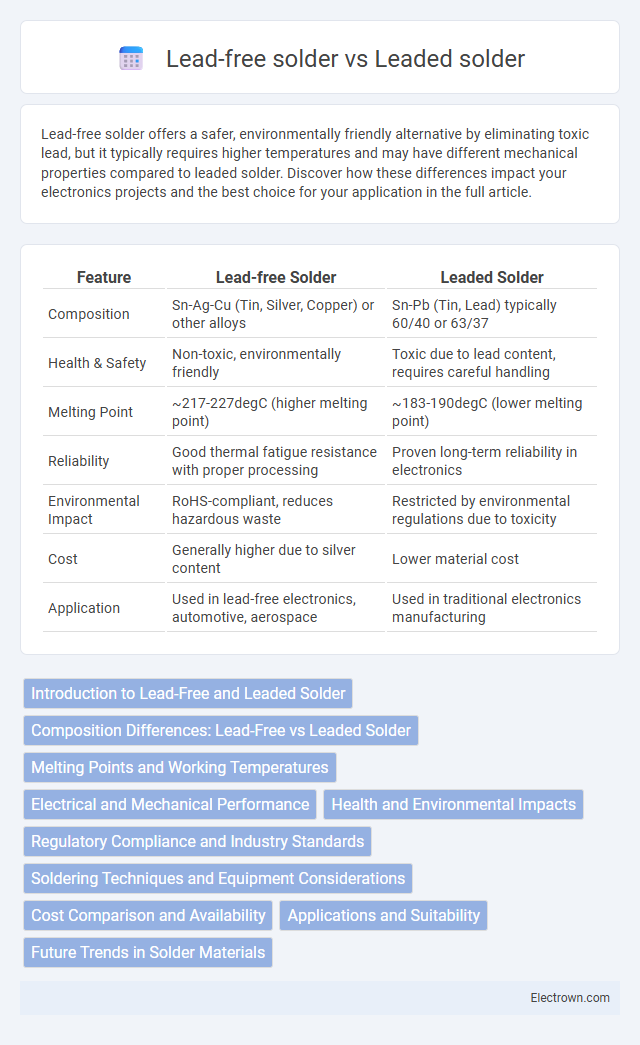

Table of Comparison

| Feature | Lead-free Solder | Leaded Solder |

|---|---|---|

| Composition | Sn-Ag-Cu (Tin, Silver, Copper) or other alloys | Sn-Pb (Tin, Lead) typically 60/40 or 63/37 |

| Health & Safety | Non-toxic, environmentally friendly | Toxic due to lead content, requires careful handling |

| Melting Point | ~217-227degC (higher melting point) | ~183-190degC (lower melting point) |

| Reliability | Good thermal fatigue resistance with proper processing | Proven long-term reliability in electronics |

| Environmental Impact | RoHS-compliant, reduces hazardous waste | Restricted by environmental regulations due to toxicity |

| Cost | Generally higher due to silver content | Lower material cost |

| Application | Used in lead-free electronics, automotive, aerospace | Used in traditional electronics manufacturing |

Introduction to Lead-Free and Leaded Solder

Lead-free solder, primarily composed of tin, silver, and copper, offers an environmentally friendly alternative to traditional leaded solder, which contains a significant percentage of lead. Leaded solder, known for its ease of use and reliable electrical conductivity, has been widely used in electronics manufacturing but raises health and environmental concerns due to lead toxicity. You should consider lead-free solder for compliance with regulations like RoHS while maintaining effective performance in modern electronic assemblies.

Composition Differences: Lead-Free vs Leaded Solder

Lead-free solder primarily consists of tin combined with metals like silver, copper, or bismuth, whereas leaded solder contains a standard alloy of 60% tin and 40% lead. The absence of lead in lead-free solder enhances environmental safety and reduces health risks but often results in a higher melting point and different mechanical properties. Your choice between these solders depends on compliance requirements and the specific performance characteristics needed for electronic assemblies.

Melting Points and Working Temperatures

Lead-free solder typically melts at higher temperatures, around 217-227degC (423-441degF), compared to leaded solder, which melts near 183-190degC (361-374degF). This higher melting point of lead-free solder requires your work environment and components to withstand increased heat during soldering to prevent damage. Selecting between lead-free and leaded solder impacts the choice of soldering equipment and temperature settings critical for effective and reliable joint formation.

Electrical and Mechanical Performance

Lead-free solder exhibits improved electrical conductivity and enhanced thermal resistance compared to leaded solder, making it suitable for high-temperature applications and reducing the risk of electrical failures. Mechanically, lead-free solder provides higher tensile strength and better fatigue resistance, which enhances joint durability under mechanical stress and thermal cycling. However, leaded solder often offers superior wetting properties and more reliable solder joint formation, contributing to easier manufacturability and lower defect rates in certain electronics assembly processes.

Health and Environmental Impacts

Lead-free solder significantly reduces toxic lead exposure, lowering health risks such as neurological damage and developmental issues in humans. Its environmentally friendly composition prevents soil and water contamination that commonly results from leaded solder disposal. Choosing lead-free solder supports safer manufacturing practices and contributes to sustainable electronic waste management for Your health and the planet.

Regulatory Compliance and Industry Standards

Lead-free solder complies with strict environmental regulations such as the RoHS directive, which restricts the use of hazardous substances in electronic products. Leaded solder, while historically favored for its reliable performance, faces increasing restrictions and is often banned in consumer electronics manufacturing to meet global safety standards. Industry standards like IPC-J-STD-006A define material requirements and testing methods, ensuring lead-free solders meet the necessary thermal and mechanical properties for regulatory compliance and product safety.

Soldering Techniques and Equipment Considerations

Lead-free solder requires higher temperature profiles, typically between 217-227degC, compared to leaded solder's melting point around 183degC, necessitating soldering equipment with precise temperature control to prevent component damage. Techniques for lead-free soldering emphasize longer preheat times and controlled cooling rates to ensure reliable joints, while using flux formulations compatible with lead-free alloys enhances wetting and reduces oxidation. Equipment such as reflow ovens and soldering irons must accommodate the increased thermal demands and be calibrated regularly to maintain optimal solder joint integrity in lead-free applications.

Cost Comparison and Availability

Lead-free solder generally costs more than leaded solder due to the use of precious metals such as silver and copper, increasing material expenses. Leaded solder remains widely available and less expensive, making it a preferred choice for budget-conscious manufacturers despite regulatory restrictions. Your decision should consider the trade-off between immediate cost savings and long-term compliance with environmental and health regulations.

Applications and Suitability

Lead-free solder is primarily used in electronics manufacturing to comply with environmental regulations like RoHS, making it suitable for consumer electronics, automotive, and aerospace industries where safety and eco-friendliness are paramount. Leaded solder, known for its lower melting point and better wettability, remains preferred in high-reliability applications such as aerospace, military, and industrial equipment where mechanical strength and thermal cycling resistance are critical. The choice between lead-free and leaded solder depends on factors like regulatory compliance, mechanical requirements, and the intended operating environment of the electronic assembly.

Future Trends in Solder Materials

Future trends in solder materials emphasize the shift from leaded solder to lead-free solder due to environmental regulations such as RoHS and WEEE directives. Lead-free solders, primarily made from tin-silver-copper (SAC) alloys, offer improved thermal fatigue resistance and are continuously being optimized for enhanced joint reliability and reduced melting points. Research explores innovative alloys and nano-enhanced solders to meet the increasing demands of miniaturized electronics and high-temperature applications.

Lead-free solder vs Leaded solder Infographic

electrown.com

electrown.com