Ag paste offers excellent electrical conductivity and cost-effectiveness, making it a popular choice for electronic applications, while Au paste provides superior corrosion resistance and enhanced bonding strength for high-reliability devices. Explore the rest of the article to understand which paste aligns with your specific needs and application requirements.

Table of Comparison

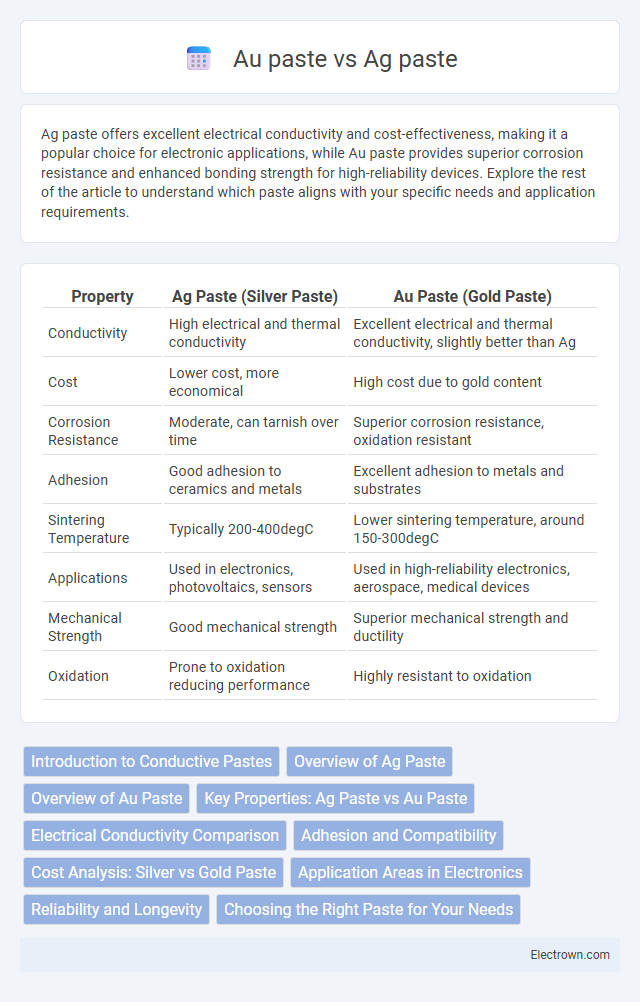

| Property | Ag Paste (Silver Paste) | Au Paste (Gold Paste) |

|---|---|---|

| Conductivity | High electrical and thermal conductivity | Excellent electrical and thermal conductivity, slightly better than Ag |

| Cost | Lower cost, more economical | High cost due to gold content |

| Corrosion Resistance | Moderate, can tarnish over time | Superior corrosion resistance, oxidation resistant |

| Adhesion | Good adhesion to ceramics and metals | Excellent adhesion to metals and substrates |

| Sintering Temperature | Typically 200-400degC | Lower sintering temperature, around 150-300degC |

| Applications | Used in electronics, photovoltaics, sensors | Used in high-reliability electronics, aerospace, medical devices |

| Mechanical Strength | Good mechanical strength | Superior mechanical strength and ductility |

| Oxidation | Prone to oxidation reducing performance | Highly resistant to oxidation |

Introduction to Conductive Pastes

Conductive pastes, such as Ag paste and Au paste, are essential materials designed to establish reliable electrical connections in electronic devices. Ag paste, primarily composed of silver particles, offers excellent conductivity and cost-effectiveness, making it widely used in photovoltaic cells and printed circuit boards. Au paste, containing gold particles, provides superior corrosion resistance and strong adhesion, ideal for high-performance applications where durability and reliability are critical for your device's longevity.

Overview of Ag Paste

Ag paste, commonly known as silver paste, is a conductive material extensively used in photovoltaic cell manufacturing and electronic packaging due to its excellent electrical conductivity and thermal stability. Its composition typically includes fine silver particles suspended in a glass frit and organic binder, enabling strong adhesion and efficient current collection on solar cells. Compared to Au paste, Ag paste offers a cost-effective alternative with superior conductivity, making it the preferred choice for large-scale industrial applications.

Overview of Au Paste

Au paste, or gold paste, offers superior electrical conductivity and corrosion resistance compared to Ag paste, making it ideal for high-reliability electronic applications such as semiconductor packaging and photovoltaic cells. Its chemical stability under extreme temperatures ensures long-term performance in harsh environments, while the fine particle size facilitates excellent adhesion and precise circuit patterning. Despite higher costs, Au paste's enhanced durability and consistent conductivity provide significant advantages in advanced microelectronics manufacturing.

Key Properties: Ag Paste vs Au Paste

Ag paste offers superior electrical conductivity and cost-effectiveness compared to Au paste, which is highly valued for its excellent corrosion resistance and stability at high temperatures. Au paste provides better long-term reliability in harsh environmental conditions, while Ag paste is preferred for applications requiring efficient conductivity and budget-friendly materials. Your choice depends on balancing conductivity needs with durability and environmental factors.

Electrical Conductivity Comparison

Ag paste exhibits superior electrical conductivity compared to Au paste due to silver's higher intrinsic conductivity, making it the preferred choice in applications requiring efficient current flow. Au paste offers stable conductivity with excellent corrosion resistance but generally has lower conductivity and higher cost, affecting performance in tightly budgeted projects. Your choice depends on balancing conductivity needs with durability and budget constraints.

Adhesion and Compatibility

Ag paste exhibits superior adhesion to ceramic and silicon substrates due to its high conductivity and moderate sintering temperature, promoting strong interfacial bonding. Au paste offers excellent compatibility with a wide range of semiconductor materials and resists oxidation, ensuring stable electrical connections in high-reliability applications. Both materials demonstrate good adhesion, but Ag paste is often preferred for cost-effective solutions while Au paste is favored for high-performance, corrosion-resistant contacts.

Cost Analysis: Silver vs Gold Paste

Silver (Ag) paste offers a significantly lower cost compared to gold (Au) paste due to the abundance and lower market price of silver, making it a more economical choice for large-scale applications. Gold paste provides superior conductivity and corrosion resistance but comes with a high price premium that can substantially increase overall manufacturing expenses. Your decision between Ag and Au paste should weigh the balance between budget constraints and performance requirements specific to your project.

Application Areas in Electronics

Ag paste excels in printed circuit boards (PCBs), LED packaging, and semiconductor devices due to its superior thermal and electrical conductivity. Au paste is preferred in high-reliability applications like aerospace, medical devices, and advanced microelectronics for its excellent corrosion resistance and stable connectivity. Your choice depends on the required conductivity, durability, and environmental conditions of the electronic components.

Reliability and Longevity

Ag paste offers superior electrical conductivity and better thermal stability, enhancing reliability in high-temperature applications. Au paste provides exceptional oxidation resistance and corrosion resistance, ensuring longer lifespan in harsh environments. Both materials contribute to device longevity, with choice depending on specific operational conditions and cost considerations.

Choosing the Right Paste for Your Needs

Selecting between Ag paste and Au paste depends on your specific application requirements such as conductivity, cost, and environmental stability. Ag paste offers excellent electrical conductivity and cost-effectiveness for general use in solar cells and electronic devices, whereas Au paste provides superior corrosion resistance and reliability in high-temperature or harsh environments. Evaluating your performance needs and budget constraints will guide you to choose the right paste for your project.

Ag paste vs Au paste Infographic

electrown.com

electrown.com