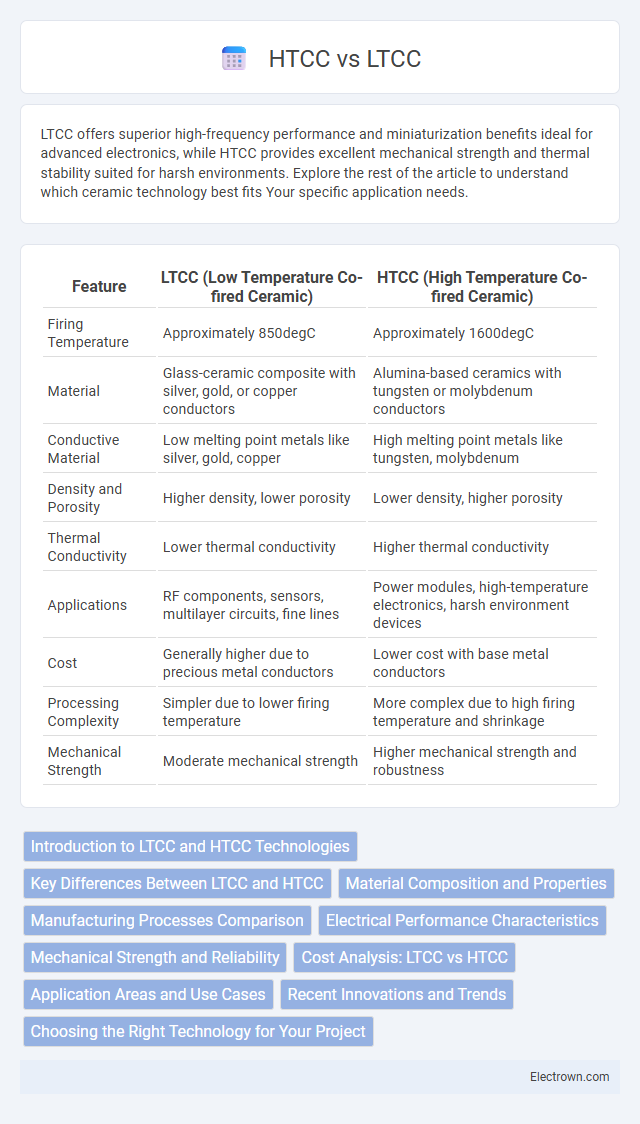

LTCC offers superior high-frequency performance and miniaturization benefits ideal for advanced electronics, while HTCC provides excellent mechanical strength and thermal stability suited for harsh environments. Explore the rest of the article to understand which ceramic technology best fits Your specific application needs.

Table of Comparison

| Feature | LTCC (Low Temperature Co-fired Ceramic) | HTCC (High Temperature Co-fired Ceramic) |

|---|---|---|

| Firing Temperature | Approximately 850degC | Approximately 1600degC |

| Material | Glass-ceramic composite with silver, gold, or copper conductors | Alumina-based ceramics with tungsten or molybdenum conductors |

| Conductive Material | Low melting point metals like silver, gold, copper | High melting point metals like tungsten, molybdenum |

| Density and Porosity | Higher density, lower porosity | Lower density, higher porosity |

| Thermal Conductivity | Lower thermal conductivity | Higher thermal conductivity |

| Applications | RF components, sensors, multilayer circuits, fine lines | Power modules, high-temperature electronics, harsh environment devices |

| Cost | Generally higher due to precious metal conductors | Lower cost with base metal conductors |

| Processing Complexity | Simpler due to lower firing temperature | More complex due to high firing temperature and shrinkage |

| Mechanical Strength | Moderate mechanical strength | Higher mechanical strength and robustness |

Introduction to LTCC and HTCC Technologies

Low Temperature Cofired Ceramics (LTCC) technology involves multilayer ceramic substrates fired at temperatures below 1000degC, offering fine feature resolution and excellent electrical performance for high-frequency applications. High Temperature Cofired Ceramics (HTCC) uses ceramic substrates fired above 1400degC, providing superior mechanical strength and thermal stability ideal for power electronics and harsh environments. Both LTCC and HTCC enable integration of passive components but differ significantly in processing temperatures, material compositions, and application suitability.

Key Differences Between LTCC and HTCC

LTCC (Low Temperature Co-fired Ceramic) and HTCC (High Temperature Co-fired Ceramic) differ primarily in their firing temperatures, with LTCC operating around 850degC and HTCC exceeding 1600degC. LTCC allows the integration of low-resistance metals like silver or gold, making it ideal for high-frequency applications, whereas HTCC uses refractory metals such as tungsten or molybdenum for enhanced mechanical strength and thermal stability. Your choice between LTCC and HTCC will depend on factors like required firing temperature, material compatibility, and the specific electrical and mechanical properties needed for the application.

Material Composition and Properties

LTCC (Low Temperature Co-fired Ceramic) primarily uses glass-ceramic composites with firing temperatures around 850-900degC, offering excellent dielectric properties and compatibility with thick film conductors. HTCC (High Temperature Co-fired Ceramic) consists mainly of alumina or other high-purity ceramics sintered above 1600degC, providing superior mechanical strength and thermal stability but limited conductor options. Understanding these material compositions helps optimize Your circuit design for specific thermal and electrical performance requirements.

Manufacturing Processes Comparison

LTCC (Low Temperature Co-fired Ceramic) manufacturing involves layering ceramic tapes with metal pastes fired at temperatures around 850degC, enabling the use of silver or gold conductors and allowing complex multilayer circuit integration. HTCC (High Temperature Co-fired Ceramic) manufacturing requires firing at higher temperatures above 1,600degC, typically using alumina-based ceramics with tungsten or molybdenum conductors, resulting in denser, more robust substrates but with limited conductor material options. Your choice depends on factors like desired electrical performance, temperature tolerance, and compatibility with conductor materials in the manufacturing process.

Electrical Performance Characteristics

LTCC (Low Temperature Co-fired Ceramic) offers superior high-frequency electrical performance and lower dielectric losses compared to HTCC (High Temperature Co-fired Ceramic), making it ideal for RF and microwave applications. HTCC provides better mechanical strength and higher thermal conductivity but typically exhibits higher dielectric constants and losses, which can affect signal integrity in high-speed circuits. Understanding your application's frequency requirements and thermal management is crucial to selecting between LTCC and HTCC for optimal electrical performance.

Mechanical Strength and Reliability

LTCC (Low-Temperature Co-fired Ceramic) offers superior mechanical strength due to its compatibility with glassy phases, resulting in reduced microcracks and enhanced fracture toughness. HTCC (High-Temperature Co-fired Ceramic), processed at higher temperatures, achieves greater material density but can experience increased brittleness and residual stresses affecting long-term reliability. In applications demanding robust mechanical stability and consistent performance under thermal cycling, LTCC generally outperforms HTCC in reliability metrics.

Cost Analysis: LTCC vs HTCC

LTCC (Low Temperature Cofired Ceramic) generally offers lower overall manufacturing costs due to its compatibility with standard metal conductors like silver and gold, enabling cost-effective mass production. HTCC (High Temperature Cofired Ceramic), while more expensive because of high-temperature processes and platinum-based conductors, provides superior mechanical strength and high-temperature performance ideal for specialized applications. Your choice depends on balancing budget constraints with performance requirements, as LTCC suits cost-sensitive projects while HTCC excels in demanding environments.

Application Areas and Use Cases

LTCC (Low Temperature Co-fired Ceramic) is widely used in RF modules, telecommunications, and medical devices due to its ability to integrate multiple layers with embedded passive components and high-frequency performance. HTCC (High Temperature Co-fired Ceramic) is preferred in power electronics, automotive sensors, and aerospace due to its superior thermal and mechanical stability under extreme conditions. Your choice between LTCC and HTCC depends on the specific requirements of your application, such as operating temperature, frequency, and environmental robustness.

Recent Innovations and Trends

Recent innovations in LTCC (Low Temperature Cofired Ceramics) emphasize enhanced multilayer integration and fine-line capabilities, supporting compact and high-frequency electronic modules. HTCC (High Temperature Cofired Ceramics) advancements focus on improved material compositions for higher thermal stability and mechanical strength, enabling robust applications in harsh environments. Trends reveal a growing preference for LTCC in RF and microwave circuits due to its superior electrical performance, while HTCC remains favored in power electronics and automotive sectors for its durability.

Choosing the Right Technology for Your Project

Selecting between Low Temperature Co-fired Ceramic (LTCC) and High Temperature Co-fired Ceramic (HTCC) depends heavily on application requirements such as operating temperature, material properties, and cost constraints. LTCC offers advantages in high-frequency circuits due to its low dielectric loss and compatibility with integrated passive components, making it ideal for RF modules and sensors. HTCC provides superior mechanical strength and thermal stability, suited for power electronics and harsh environment applications where durability is critical.

LTCC vs HTCC Infographic

electrown.com

electrown.com