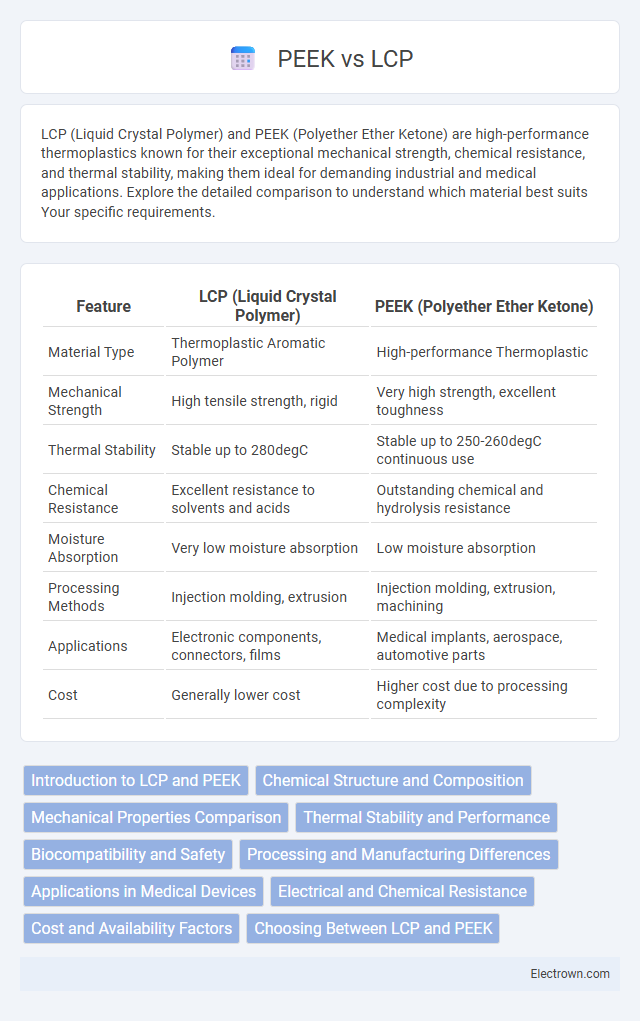

LCP (Liquid Crystal Polymer) and PEEK (Polyether Ether Ketone) are high-performance thermoplastics known for their exceptional mechanical strength, chemical resistance, and thermal stability, making them ideal for demanding industrial and medical applications. Explore the detailed comparison to understand which material best suits Your specific requirements.

Table of Comparison

| Feature | LCP (Liquid Crystal Polymer) | PEEK (Polyether Ether Ketone) |

|---|---|---|

| Material Type | Thermoplastic Aromatic Polymer | High-performance Thermoplastic |

| Mechanical Strength | High tensile strength, rigid | Very high strength, excellent toughness |

| Thermal Stability | Stable up to 280degC | Stable up to 250-260degC continuous use |

| Chemical Resistance | Excellent resistance to solvents and acids | Outstanding chemical and hydrolysis resistance |

| Moisture Absorption | Very low moisture absorption | Low moisture absorption |

| Processing Methods | Injection molding, extrusion | Injection molding, extrusion, machining |

| Applications | Electronic components, connectors, films | Medical implants, aerospace, automotive parts |

| Cost | Generally lower cost | Higher cost due to processing complexity |

Introduction to LCP and PEEK

Liquid Crystal Polymer (LCP) is a high-performance thermoplastic known for its exceptional mechanical strength, thermal stability, and chemical resistance, making it ideal for electronics and automotive components. Polyether Ether Ketone (PEEK) is a semi-crystalline engineering polymer prized for its outstanding mechanical properties, high-temperature resistance up to 250degC, and excellent chemical inertness, widely used in aerospace, medical, and industrial applications. Both materials offer unique advantages in durability and performance, with LCP excelling in precision molding and PEEK in structural applications requiring long-term stability under harsh conditions.

Chemical Structure and Composition

LCP (Liquid Crystal Polymer) consists of aromatic polyester chains with rigid rod-like molecular structures, providing high mechanical strength and thermal stability. PEEK (Polyether Ether Ketone) features a semi-crystalline polymer backbone containing ether and ketone linkages, offering exceptional chemical resistance and toughness. Your choice between LCP and PEEK depends on specific chemical composition requirements impacting performance in demanding environments.

Mechanical Properties Comparison

LCP (Liquid Crystal Polymer) exhibits exceptional tensile strength, stiffness, and dimensional stability, making it ideal for high-performance mechanical applications. PEEK (Polyether Ether Ketone) offers superior impact resistance and fatigue strength with excellent chemical and thermal stability up to 250degC. Comparing mechanical properties, LCP provides higher modulus and rigidity, while PEEK delivers enhanced toughness and long-term durability under cyclic loads.

Thermal Stability and Performance

LCP (Liquid Crystal Polymer) exhibits superior thermal stability with a melting point above 280degC, making it ideal for high-temperature applications, whereas PEEK (Polyether Ether Ketone) offers outstanding thermal performance with a continuous use temperature up to 250degC and exceptional chemical resistance. LCP's unique molecular structure provides excellent dimensional stability under thermal stress, while PEEK balances high mechanical strength with thermal endurance in extreme environments. Both materials deliver reliable performance in aerospace, automotive, and electronics, but LCP is preferred for very high-temperature scenarios and fast processing cycles, whereas PEEK excels in long-term thermal stability and toughness.

Biocompatibility and Safety

LCP (Liquid Crystal Polymer) and PEEK (Polyether Ether Ketone) both exhibit excellent biocompatibility, making them suitable for medical implants and devices. LCP offers superior chemical resistance and minimal moisture absorption, reducing the risk of inflammatory responses, while PEEK's mechanical properties closely mimic human bone, promoting safer long-term implantation. Safety profiles indicate both materials are non-toxic and exhibit low allergenic potential, but PEEK's radiolucency allows better imaging follow-up post-implantation.

Processing and Manufacturing Differences

LCP (Liquid Crystal Polymer) offers high-temperature resistance and fast cycle times with injection molding, enabling complex shapes and thin walls, whereas PEEK (Polyether Ether Ketone) demands higher processing temperatures and slower cooling, leading to longer cycle times and specialized equipment. PEEK's semicrystalline structure requires precise temperature control during extrusion and molding to maintain mechanical properties, while LCP's unique molecular orientation allows for easier flow and better dimensional stability. Manufacturing with PEEK often involves higher energy consumption and costs compared to LCP, impacting overall production efficiency and scalability.

Applications in Medical Devices

LCP (Liquid Crystal Polymer) and PEEK (Polyether Ether Ketone) are both high-performance polymers widely used in medical devices due to their biocompatibility and sterilization resistance. LCP is favored in microelectronic medical components and catheters because of its excellent dimensional stability and low moisture absorption, while PEEK is commonly used for implants, spinal cages, and orthopedic devices due to its superior mechanical strength and chemical resistance. When selecting materials for your medical device, consider LCP for intricate, electrically sensitive parts and PEEK for load-bearing implants that require long-term durability.

Electrical and Chemical Resistance

LCP (Liquid Crystal Polymer) offers superior electrical resistance with low dielectric constant and stable insulating properties, making it ideal for high-frequency electronic applications. PEEK (Polyether Ether Ketone) exhibits excellent chemical resistance, maintaining integrity against solvents, acids, and alkalis, which suits harsh chemical environments. Your choice depends on whether electrical performance or chemical durability is the primary concern for your application.

Cost and Availability Factors

LCP (Liquid Crystal Polymer) generally has a higher cost compared to PEEK (Polyether Ether Ketone) due to its specialized manufacturing processes and limited production scale. PEEK is more widely available in various grades and forms, benefiting from broader industrial applications that drive economies of scale and reduce material costs. The global supply chain for PEEK is more established, ensuring consistent availability and competitive pricing relative to the niche market positioning of LCP.

Choosing Between LCP and PEEK

Choosing between LCP and PEEK depends heavily on your application's mechanical and thermal requirements. LCP offers superior strength, chemical resistance, and dimensional stability, making it ideal for high-performance electronic components and precision parts. PEEK provides excellent thermal resistance and biocompatibility, often favored for medical implants and aerospace applications where long-term durability under extreme conditions is essential.

LCP vs PEEK Infographic

electrown.com

electrown.com