Soft magnetic materials exhibit low coercivity and high permeability, making them ideal for applications requiring rapid magnetization and demagnetization, such as transformers and inductors. Explore the differences between soft and hard magnetic materials further to understand how your choice impacts device performance and efficiency.

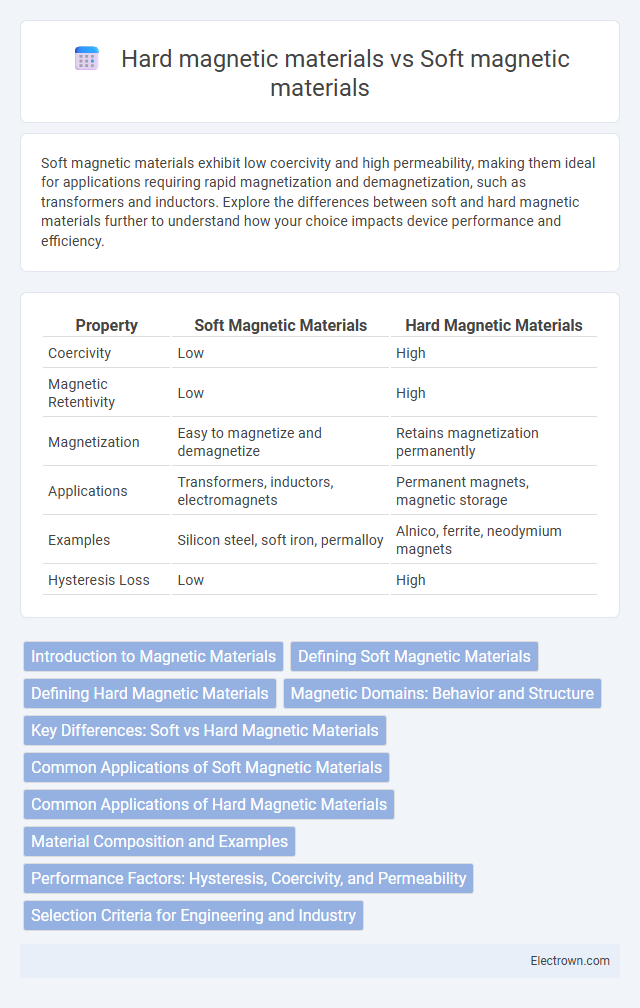

Table of Comparison

| Property | Soft Magnetic Materials | Hard Magnetic Materials |

|---|---|---|

| Coercivity | Low | High |

| Magnetic Retentivity | Low | High |

| Magnetization | Easy to magnetize and demagnetize | Retains magnetization permanently |

| Applications | Transformers, inductors, electromagnets | Permanent magnets, magnetic storage |

| Examples | Silicon steel, soft iron, permalloy | Alnico, ferrite, neodymium magnets |

| Hysteresis Loss | Low | High |

Introduction to Magnetic Materials

Soft magnetic materials exhibit low coercivity and high permeability, making them ideal for applications requiring rapid magnetization and demagnetization, such as transformers and inductors. Hard magnetic materials possess high coercivity and remanence, enabling permanent magnetization suitable for permanent magnets in motors and generators. The distinction between these materials lies in their atomic structure and magnetic domain behavior, which directly influence their magnetic hysteresis characteristics.

Defining Soft Magnetic Materials

Soft magnetic materials exhibit low coercivity and high magnetic permeability, allowing them to magnetize and demagnetize rapidly with minimal energy loss. Common examples include silicon steel and soft iron, widely used in transformer cores and inductors due to their efficient magnetic response. These materials enable efficient electromagnetic device performance by minimizing hysteresis losses during alternating magnetic field cycles.

Defining Hard Magnetic Materials

Hard magnetic materials are characterized by their high coercivity and ability to retain significant magnetization after an external magnetic field is removed, making them ideal for permanent magnets used in motors, sensors, and memory devices. These materials, such as Alnico, ferrites, and rare-earth alloys like neodymium-iron-boron, exhibit strong resistance to demagnetization and are essential in applications requiring stable and long-lasting magnetic performance. Understanding the properties of hard magnetic materials helps you select the right magnet type for durable and efficient electromagnetic systems.

Magnetic Domains: Behavior and Structure

Soft magnetic materials feature magnetic domains that easily realign under an external magnetic field, resulting in low coercivity and minimal energy loss during magnetization cycles. Hard magnetic materials possess rigidly pinned domains that maintain their orientation even after the external field is removed, giving them high coercivity and permanent magnetization. Understanding the behavior and structure of these magnetic domains enables you to select the right material for applications requiring efficient magnetic switching or stable, long-lasting magnetic retention.

Key Differences: Soft vs Hard Magnetic Materials

Soft magnetic materials exhibit low coercivity and high permeability, making them ideal for applications requiring easy magnetization and demagnetization, such as transformers and inductors. Hard magnetic materials possess high coercivity and remanence, ensuring permanent magnetization ideal for use in motors, generators, and magnetic storage devices. Understanding these key differences helps you select the appropriate material based on whether temporary or permanent magnetic properties are essential for your application.

Common Applications of Soft Magnetic Materials

Soft magnetic materials, known for their high permeability and low coercivity, are widely used in transformers, inductors, and electric motors to efficiently channel magnetic flux with minimal energy loss. These materials, such as silicon steel and soft iron, are essential in the cores of electromagnetic devices, enabling rapid magnetization and demagnetization cycles. Common applications also include magnetic shielding and actuators, where soft magnetic properties enhance performance and energy efficiency.

Common Applications of Hard Magnetic Materials

Hard magnetic materials are widely used in permanent magnets found in electric motors, generators, and magnetic storage devices due to their high coercivity and ability to retain magnetization. These materials are essential in speakers, magnetic locks, and various types of sensors where a stable magnetic field is crucial. Your choice of hard magnetic materials significantly impacts the efficiency and durability of these applications.

Material Composition and Examples

Soft magnetic materials, such as silicon steel and permalloy, are primarily composed of iron with small amounts of silicon or nickel, optimizing their low coercivity and high permeability for applications like transformers and inductors. Hard magnetic materials, including alnico alloys and neodymium-iron-boron (NdFeB), consist of iron, cobalt, nickel, and rare earth elements, designed for high coercivity to maintain permanent magnetization in motors and magnetic storage. Your choice between these materials depends on the required magnetic properties for efficient performance in specific applications.

Performance Factors: Hysteresis, Coercivity, and Permeability

Soft magnetic materials exhibit low coercivity and narrow hysteresis loops, enabling high permeability and efficient magnetization reversal with minimal energy loss, making them ideal for transformer cores and inductors. Hard magnetic materials possess high coercivity and wide hysteresis loops, which provide strong remanence and resistance to demagnetization, essential for permanent magnets in motors and data storage. Understanding these performance factors helps you select the right magnetic material tailored to your specific application needs.

Selection Criteria for Engineering and Industry

Soft magnetic materials are chosen for applications requiring rapid magnetization and demagnetization, such as transformers, inductors, and electric motors, due to their high permeability and low coercivity. Hard magnetic materials are preferred in permanent magnets, data storage, and sensors where sustained magnetic performance and resistance to demagnetization are critical, characterized by high coercivity and remanence. Selection depends on factors like operational frequency, magnetic field strength, thermal stability, and mechanical properties tailored to specific industrial requirements.

Soft magnetic vs Hard magnetic materials Infographic

electrown.com

electrown.com