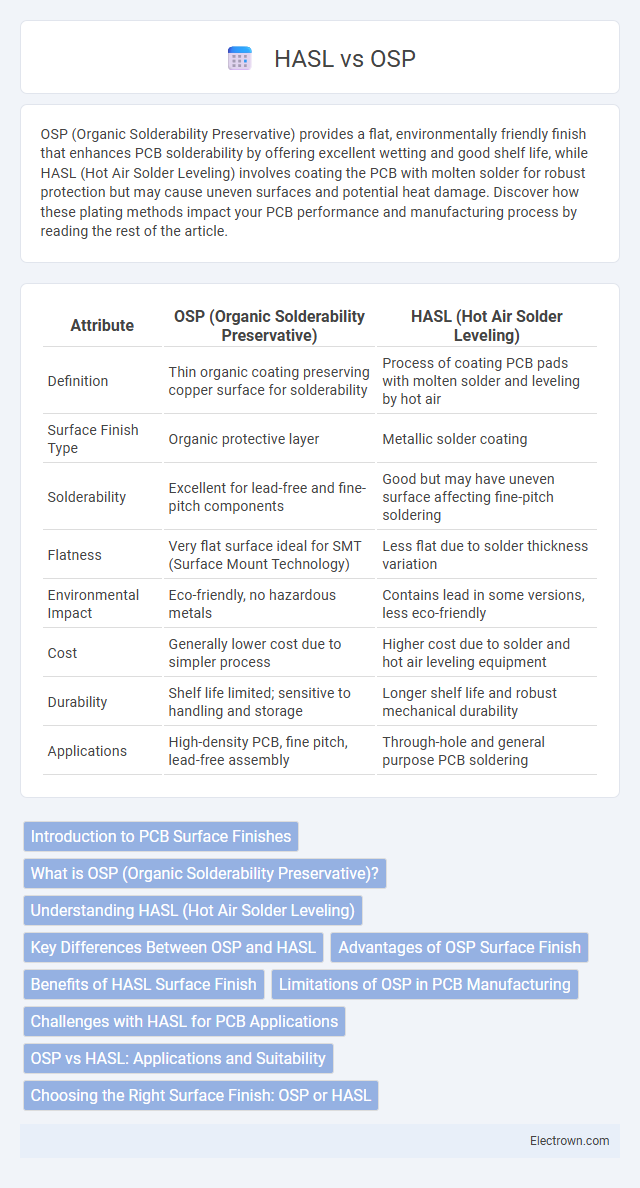

OSP (Organic Solderability Preservative) provides a flat, environmentally friendly finish that enhances PCB solderability by offering excellent wetting and good shelf life, while HASL (Hot Air Solder Leveling) involves coating the PCB with molten solder for robust protection but may cause uneven surfaces and potential heat damage. Discover how these plating methods impact your PCB performance and manufacturing process by reading the rest of the article.

Table of Comparison

| Attribute | OSP (Organic Solderability Preservative) | HASL (Hot Air Solder Leveling) |

|---|---|---|

| Definition | Thin organic coating preserving copper surface for solderability | Process of coating PCB pads with molten solder and leveling by hot air |

| Surface Finish Type | Organic protective layer | Metallic solder coating |

| Solderability | Excellent for lead-free and fine-pitch components | Good but may have uneven surface affecting fine-pitch soldering |

| Flatness | Very flat surface ideal for SMT (Surface Mount Technology) | Less flat due to solder thickness variation |

| Environmental Impact | Eco-friendly, no hazardous metals | Contains lead in some versions, less eco-friendly |

| Cost | Generally lower cost due to simpler process | Higher cost due to solder and hot air leveling equipment |

| Durability | Shelf life limited; sensitive to handling and storage | Longer shelf life and robust mechanical durability |

| Applications | High-density PCB, fine pitch, lead-free assembly | Through-hole and general purpose PCB soldering |

Introduction to PCB Surface Finishes

PCB surface finishes like Organic Solderability Preservative (OSP) and Hot Air Solder Leveling (HASL) play crucial roles in protecting copper circuits and ensuring solderability during assembly. OSP offers a thin, organic coating ideal for fine-pitch components and environmental friendliness, while HASL provides a robust, traditional finish with excellent solderability through a layer of molten solder evenly applied and leveled by hot air knives. Choosing the right finish affects your PCB's reliability, assembly process, and long-term performance in electronic applications.

What is OSP (Organic Solderability Preservative)?

OSP (Organic Solderability Preservative) is a thin, organic coating applied to copper surfaces on printed circuit boards (PCBs) to prevent oxidation and maintain solderability during storage and assembly. It offers a cost-effective, environmentally friendly alternative to HASL (Hot Air Solder Leveling) by providing a flat, lead-free surface ideal for fine-pitch components and high-density PCB designs. Your choice of OSP ensures excellent solder joint reliability while simplifying the soldering process and reducing cleaning requirements.

Understanding HASL (Hot Air Solder Leveling)

HASL (Hot Air Solder Leveling) is a surface finish process in PCB manufacturing where molten solder is applied to the board, then leveled by hot air knives to create a uniform coating. This finish provides excellent solderability and protects copper pads from oxidation, ensuring reliable electrical connections. While HASL is cost-effective and widely used, it may introduce uneven surfaces compared to OSP (Organic Solderability Preservative), which offers a flat surface suitable for fine-pitch components.

Key Differences Between OSP and HASL

OSP (Organic Solderability Preservative) provides a thin, environmentally friendly organic layer that preserves copper pads from oxidation on printed circuit boards, ensuring excellent solderability and flatness crucial for fine-pitch components. HASL (Hot Air Solder Leveling) involves coating PCB pads with molten solder followed by hot air leveling, resulting in a thicker, more durable finish with better mechanical strength but less flatness compared to OSP. The primary differences lie in OSP's lead-free, planar surface suited for precise assemblies versus HASL's robust, thicker solder layer beneficial for through-hole components and heavier solder joints.

Advantages of OSP Surface Finish

OSP (Organic Solderability Preservative) offers superior flatness and a thin, uniform coating that improves solderability compared to HASL (Hot Air Solder Leveling). It reduces the risk of thermal stress and warping on delicate PCB substrates, enhancing reliability for fine-pitch components and high-density interconnects. OSP also provides an environmentally friendly, lead-free alternative with excellent wettability and longer shelf life for PCB assemblies.

Benefits of HASL Surface Finish

HASL surface finish offers excellent solderability due to its smooth, uniform coating of molten solder, ensuring reliable electrical connections for your printed circuit boards. This finish provides robust protection against oxidation and corrosion, extending the PCB's lifespan in demanding environments. Compared to OSP, HASL's thermal resilience supports multiple reflow cycles, making it ideal for complex assembly processes and high-reliability applications.

Limitations of OSP in PCB Manufacturing

OSP (Organic Solderability Preservative) in PCB manufacturing faces limitations such as lower thermal durability and susceptibility to damage during multiple reflows, which can affect solder joint reliability. Unlike HASL (Hot Air Solder Leveling), OSP coatings are thinner and provide less mechanical protection, making them less suitable for complex or multilayer boards requiring extended shelf life. Your choice between OSP and HASL should consider these factors to ensure optimal solderability and board performance.

Challenges with HASL for PCB Applications

HASL (Hot Air Solder Leveling) presents challenges in PCB applications due to its uneven surface finish, which can impair fine-pitch component soldering and lead to poor solder joint reliability. The process involves exposure to high temperatures, causing potential thermal stress and warping of sensitive substrates such as FR-4 or HDI boards. In contrast, OSP (Organic Solderability Preservative) offers a flat and uniform finish that enhances solderability and reduces the risk of solder bridging, making it more suitable for modern, high-density PCB designs.

OSP vs HASL: Applications and Suitability

OSP (Organic Solderability Preservative) provides superior protection against oxidation, making it ideal for high-frequency and fine-pitch applications, while HASL (Hot Air Solder Leveling) offers a robust and cost-effective option suitable for through-hole and general-purpose PCB assemblies. OSP ensures excellent solderability for lead-free processes and is favored in consumer electronics, whereas HASL's durability suits harsher environmental conditions and manual soldering. Choosing between OSP and HASL depends on Your PCB design requirements, production volume, and the specific electrical and mechanical performance needed.

Choosing the Right Surface Finish: OSP or HASL

Choosing between Organic Solderability Preservative (OSP) and Hot Air Solder Leveling (HASL) depends on factors like board complexity, environmental considerations, and thermal tolerance. OSP offers a thin, flat, and environmentally friendly coating ideal for fine-pitch components and multiple reflows but has a limited shelf life. HASL provides excellent solderability with a thicker, more robust finish suitable for through-hole components and boards requiring high thermal resistance but may cause uneven surfaces and is less eco-friendly.

OSP vs HASL Infographic

electrown.com

electrown.com