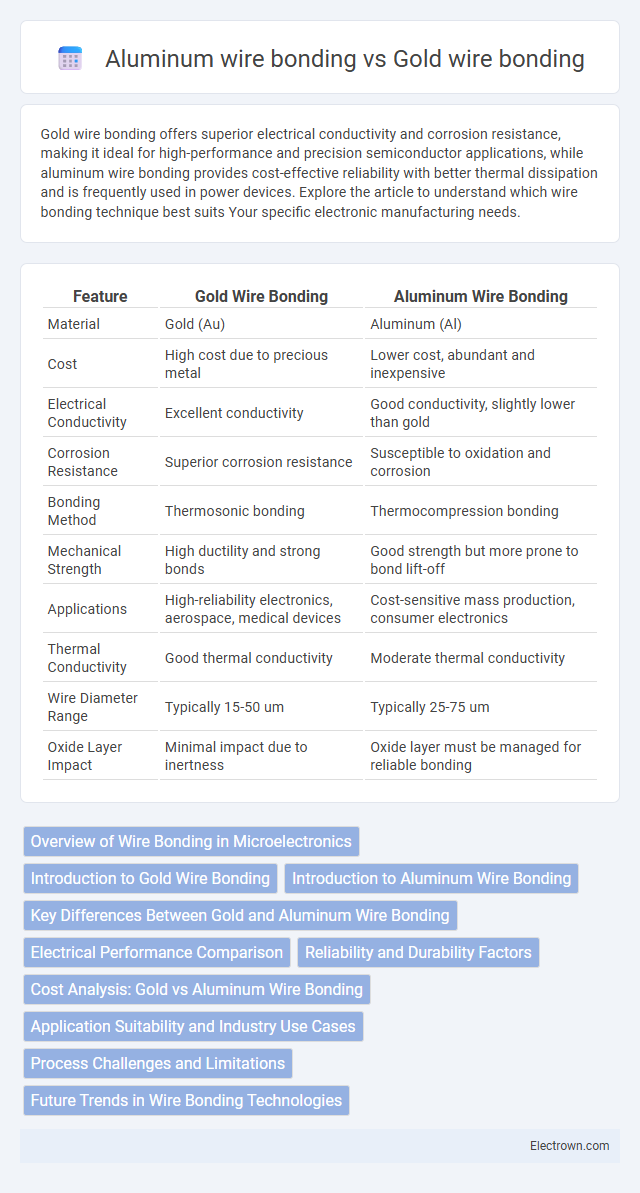

Gold wire bonding offers superior electrical conductivity and corrosion resistance, making it ideal for high-performance and precision semiconductor applications, while aluminum wire bonding provides cost-effective reliability with better thermal dissipation and is frequently used in power devices. Explore the article to understand which wire bonding technique best suits Your specific electronic manufacturing needs.

Table of Comparison

| Feature | Gold Wire Bonding | Aluminum Wire Bonding |

|---|---|---|

| Material | Gold (Au) | Aluminum (Al) |

| Cost | High cost due to precious metal | Lower cost, abundant and inexpensive |

| Electrical Conductivity | Excellent conductivity | Good conductivity, slightly lower than gold |

| Corrosion Resistance | Superior corrosion resistance | Susceptible to oxidation and corrosion |

| Bonding Method | Thermosonic bonding | Thermocompression bonding |

| Mechanical Strength | High ductility and strong bonds | Good strength but more prone to bond lift-off |

| Applications | High-reliability electronics, aerospace, medical devices | Cost-sensitive mass production, consumer electronics |

| Thermal Conductivity | Good thermal conductivity | Moderate thermal conductivity |

| Wire Diameter Range | Typically 15-50 um | Typically 25-75 um |

| Oxide Layer Impact | Minimal impact due to inertness | Oxide layer must be managed for reliable bonding |

Overview of Wire Bonding in Microelectronics

Wire bonding in microelectronics is a critical interconnection technology that uses fine metal wires to connect semiconductor devices to their packages. Gold wire bonding excels in reliability, corrosion resistance, and conductivity, making it ideal for high-performance and high-reliability applications such as aerospace and medical implants. Aluminum wire bonding offers cost-effectiveness and better compatibility with aluminum pads, commonly used in mass production of consumer electronics and integrated circuits.

Introduction to Gold Wire Bonding

Gold wire bonding utilizes high-purity gold wires, typically 99.99% pure, to create reliable electrical connections in semiconductor devices, offering superior conductivity and corrosion resistance compared to other metals. This method is favored in high-performance and high-reliability applications such as aerospace, medical devices, and advanced microelectronics due to gold's excellent ductility and bondability. The process involves thermosonic bonding, which combines ultrasonic energy, pressure, and heat to form strong metallurgical bonds between the gold wire and the substrate.

Introduction to Aluminum Wire Bonding

Aluminum wire bonding offers a cost-effective and reliable alternative to gold wire bonding, especially in high-volume semiconductor manufacturing. Its superior resistance to electromigration and better compatibility with certain substrates make aluminum a preferred choice for high-frequency and power devices. Choosing aluminum wire bonding enhances your production efficiency while maintaining excellent electrical connectivity and mechanical strength.

Key Differences Between Gold and Aluminum Wire Bonding

Gold wire bonding offers superior electrical conductivity and corrosion resistance compared to aluminum wire bonding, making it ideal for high-reliability applications in aerospace and medical devices. Aluminum wire bonding is more cost-effective and provides better thermal dissipation, frequently used in consumer electronics and power devices. The choice between gold and aluminum wire bonding depends on factors like cost sensitivity, reliability requirements, and environmental conditions.

Electrical Performance Comparison

Gold wire bonding offers superior electrical conductivity and lower contact resistance compared to aluminum wire bonding, making it ideal for high-frequency and high-reliability applications. Aluminum wire bonding, while having higher resistivity, provides better performance in terms of thermal stability and electromigration resistance in power devices. Both materials exhibit distinct electrical characteristics influencing their selection based on device requirements and operating conditions.

Reliability and Durability Factors

Gold wire bonding offers superior reliability due to its excellent corrosion resistance, stable electrical conductivity, and ability to withstand high temperatures, making it ideal for high-performance microelectronic applications. Aluminum wire bonding provides cost-effective durability with strong mechanical properties and good oxidation resistance, but it may suffer from issues like aluminum balling and higher susceptibility to corrosion under harsh environmental conditions. The choice between gold and aluminum wire bonding depends on balancing long-term reliability demands with budget constraints and specific application requirements.

Cost Analysis: Gold vs Aluminum Wire Bonding

Gold wire bonding offers superior electrical conductivity and reliability but comes at a significantly higher cost compared to aluminum wire bonding, which is more economical and widely used in large-scale semiconductor production. The price of gold fluctuates due to market conditions, impacting the overall production cost, while aluminum's stable pricing enables better budget predictability for your projects. Choosing between gold and aluminum wire bonding depends largely on balancing performance requirements with cost efficiency.

Application Suitability and Industry Use Cases

Gold wire bonding offers superior corrosion resistance and excellent electrical conductivity, making it ideal for high-reliability applications in aerospace, medical devices, and high-frequency communication systems. Aluminum wire bonding provides cost-effective solutions with good thermal conductivity, extensively used in automotive electronics, power modules, and consumer electronics where budget and heat dissipation are critical. The choice between gold and aluminum wire bonding hinges on specific industry requirements, balancing performance, cost, and environmental factors.

Process Challenges and Limitations

Gold wire bonding faces challenges such as higher material cost and susceptibility to gold-aluminum intermetallic formation leading to bond reliability issues in mixed-metal interfaces. Aluminum wire bonding encounters limitations including increased susceptibility to corrosion and oxide layer formation, which complicates the bonding process and may require specialized equipment or surface treatments. Both processes demand precise control over temperature, ultrasonic energy, and bonding force, with gold providing better conductivity but aluminum offering cost-effective scalability despite its process sensitivities.

Future Trends in Wire Bonding Technologies

Gold wire bonding remains favored for its superior electrical conductivity and resistance to corrosion, making it essential in high-reliability applications like aerospace and medical devices. Aluminum wire bonding is gaining momentum due to cost efficiency and compatibility with silicon-based devices, driving innovation in automotive and consumer electronics industries. Emerging trends emphasize ultra-fine wire diameters, advanced wedge bonding methods, and the integration of copper wire bonding to balance performance, durability, and production scalability in semiconductor packaging.

Gold wire bonding vs Aluminum wire bonding Infographic

electrown.com

electrown.com