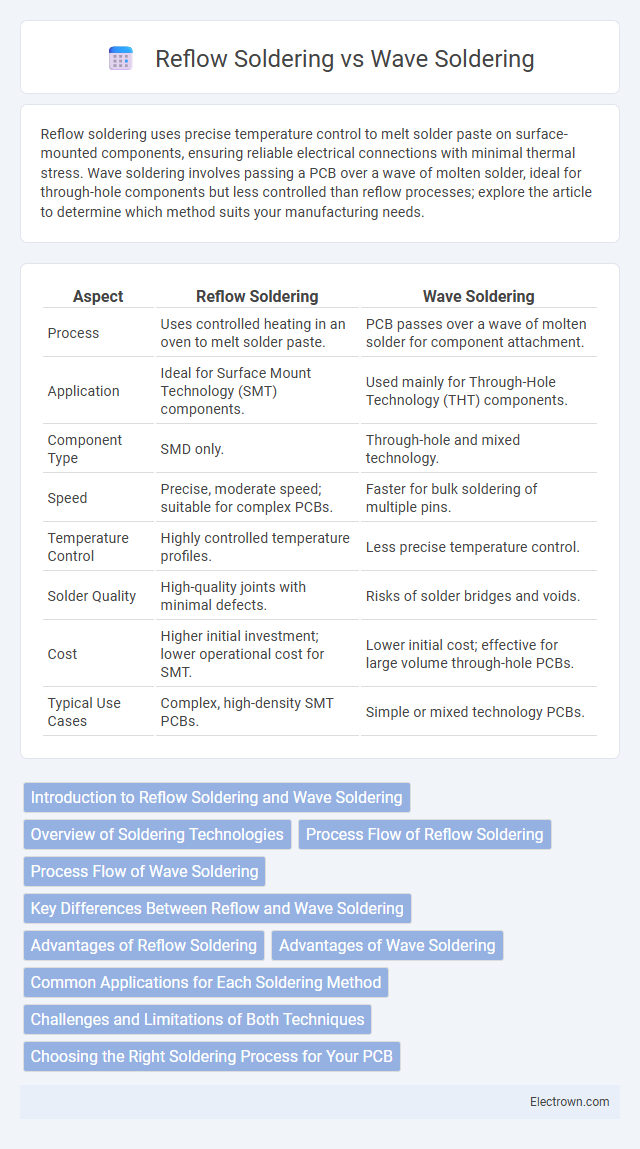

Reflow soldering uses precise temperature control to melt solder paste on surface-mounted components, ensuring reliable electrical connections with minimal thermal stress. Wave soldering involves passing a PCB over a wave of molten solder, ideal for through-hole components but less controlled than reflow processes; explore the article to determine which method suits your manufacturing needs.

Table of Comparison

| Aspect | Reflow Soldering | Wave Soldering |

|---|---|---|

| Process | Uses controlled heating in an oven to melt solder paste. | PCB passes over a wave of molten solder for component attachment. |

| Application | Ideal for Surface Mount Technology (SMT) components. | Used mainly for Through-Hole Technology (THT) components. |

| Component Type | SMD only. | Through-hole and mixed technology. |

| Speed | Precise, moderate speed; suitable for complex PCBs. | Faster for bulk soldering of multiple pins. |

| Temperature Control | Highly controlled temperature profiles. | Less precise temperature control. |

| Solder Quality | High-quality joints with minimal defects. | Risks of solder bridges and voids. |

| Cost | Higher initial investment; lower operational cost for SMT. | Lower initial cost; effective for large volume through-hole PCBs. |

| Typical Use Cases | Complex, high-density SMT PCBs. | Simple or mixed technology PCBs. |

Introduction to Reflow Soldering and Wave Soldering

Reflow soldering uses controlled heat to melt solder paste applied on surface-mount components, creating precise electrical and mechanical connections on PCBs. Wave soldering involves passing a PCB over a heated wave of molten solder, efficiently soldering through-hole components on the board's underside. Both methods optimize assembly processes by targeting different component types and PCB designs, ensuring reliable circuit performance.

Overview of Soldering Technologies

Reflow soldering uses controlled heat to melt solder paste applied on surface-mount components, ensuring precise and uniform joints ideal for complex and high-density PCB assemblies. Wave soldering involves passing a PCB over a wave of molten solder to connect through-hole components quickly and efficiently, making it suitable for larger production runs or boards with mixed technology. Your choice between these soldering technologies depends on the specific assembly requirements, component types, and production volume.

Process Flow of Reflow Soldering

Reflow soldering begins with applying solder paste onto PCB pads, followed by precise component placement using automated pick-and-place machines. The assembly then passes through a reflow oven where controlled temperature zones gradually melt the solder, ensuring strong metallurgical bonds between components and PCB. This process enhances solder joint reliability and minimizes thermal stress compared to wave soldering methods.

Process Flow of Wave Soldering

Wave soldering involves a process flow that begins with flux application to clean and prepare the PCB surface, followed by preheating to activate the flux and reduce thermal shock. The PCB then moves over a wave of molten solder, where solder adheres to exposed metal surfaces and component leads, creating reliable electrical connections. Cooling solidifies the solder joints, ensuring durability and electrical integrity for your assembled circuit boards.

Key Differences Between Reflow and Wave Soldering

Reflow soldering uses solder paste heated by infrared or convection to attach surface-mounted components, while wave soldering involves passing the PCB over a molten solder wave to solder through-hole components. Reflow soldering delivers precise temperature control and is ideal for fine-pitch components, whereas wave soldering offers faster processing for double-sided or through-hole assemblies. Your choice depends on component type and production volume, as reflow caters to surface mount technology and wave suits bulkier or mixed-technology boards.

Advantages of Reflow Soldering

Reflow soldering offers precise temperature control, enabling uniform heating and reducing thermal stress on components, which enhances the reliability of your electronic assemblies. This method is highly suitable for complex and fine-pitch SMT components, providing superior solder joints with minimal defects compared to wave soldering. Its adaptability to automated production lines increases efficiency and consistency, making reflow soldering advantageous for high-volume manufacturing.

Advantages of Wave Soldering

Wave soldering offers high throughput and consistent solder joint quality, making it ideal for mass production of through-hole components. It provides excellent solder coverage for complex PCB assemblies and reduces manual labor compared to manual soldering techniques. The process is highly reliable, with superior thermal control minimizing defects and ensuring strong mechanical and electrical connections.

Common Applications for Each Soldering Method

Reflow soldering is commonly used for surface mount technology (SMT) components in printed circuit board (PCB) assembly, especially in consumer electronics, automotive electronics, and medical devices requiring precise, small-scale solder joints. Wave soldering is typically applied for through-hole components and mixed-technology boards in industries such as telecommunications, industrial control systems, and large-scale manufacturing where high volume and consistent soldering are essential. Choosing the right method for your production depends on the component types and assembly volume, optimizing efficiency and reliability.

Challenges and Limitations of Both Techniques

Reflow soldering faces challenges with uneven heat distribution, which can cause component damage or incomplete solder joints on complex PCBs. Wave soldering is limited by its inability to effectively solder fine-pitch or densely packed components, leading to bridging or insufficient soldering. Both techniques require precise thermal profiling and process control to minimize defects, but their suitability varies depending on PCB design complexity and component type.

Choosing the Right Soldering Process for Your PCB

Selecting the appropriate soldering process for your PCB depends on factors such as component type, production volume, and thermal sensitivity. Reflow soldering is ideal for surface-mount technology (SMT) components, offering precise temperature control and reduced risk of damage, while wave soldering suits through-hole components and high-volume production with faster throughput. Evaluating PCB design complexity, component layout, and cost considerations ensures optimal solder joint quality and manufacturing efficiency.

reflow soldering vs wave soldering Infographic

electrown.com

electrown.com