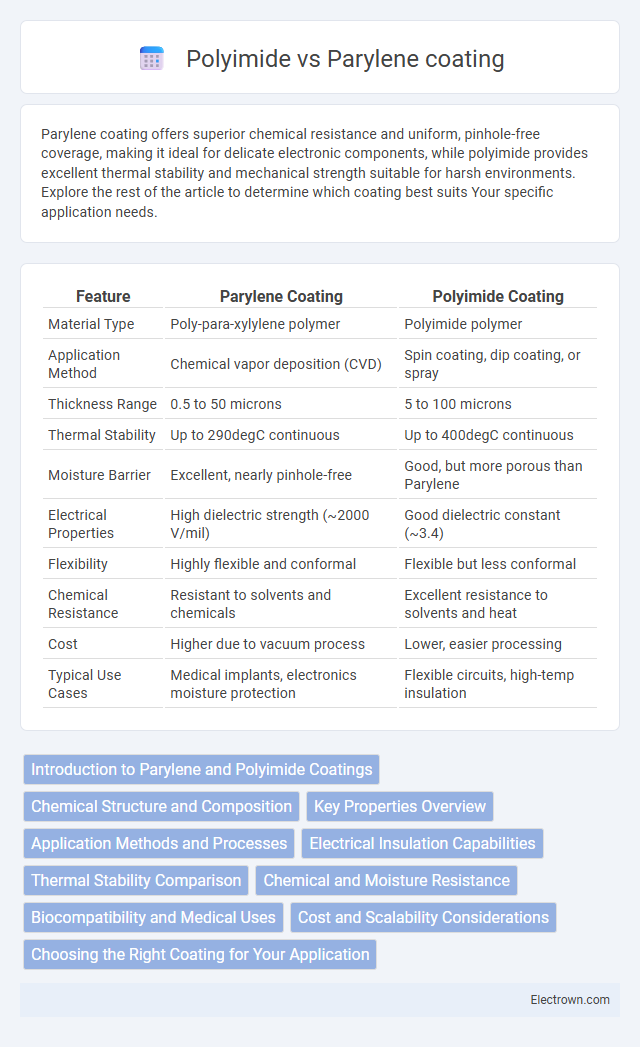

Parylene coating offers superior chemical resistance and uniform, pinhole-free coverage, making it ideal for delicate electronic components, while polyimide provides excellent thermal stability and mechanical strength suitable for harsh environments. Explore the rest of the article to determine which coating best suits Your specific application needs.

Table of Comparison

| Feature | Parylene Coating | Polyimide Coating |

|---|---|---|

| Material Type | Poly-para-xylylene polymer | Polyimide polymer |

| Application Method | Chemical vapor deposition (CVD) | Spin coating, dip coating, or spray |

| Thickness Range | 0.5 to 50 microns | 5 to 100 microns |

| Thermal Stability | Up to 290degC continuous | Up to 400degC continuous |

| Moisture Barrier | Excellent, nearly pinhole-free | Good, but more porous than Parylene |

| Electrical Properties | High dielectric strength (~2000 V/mil) | Good dielectric constant (~3.4) |

| Flexibility | Highly flexible and conformal | Flexible but less conformal |

| Chemical Resistance | Resistant to solvents and chemicals | Excellent resistance to solvents and heat |

| Cost | Higher due to vacuum process | Lower, easier processing |

| Typical Use Cases | Medical implants, electronics moisture protection | Flexible circuits, high-temp insulation |

Introduction to Parylene and Polyimide Coatings

Parylene coating is a thin, uniform polymer layer known for its excellent dielectric properties, chemical resistance, and biocompatibility, commonly used in medical devices and electronics. Polyimide coating offers high thermal stability, mechanical strength, and excellent electrical insulation, making it ideal for flexible circuits and aerospace applications. Both materials provide protective barriers but differ significantly in deposition methods and performance characteristics under extreme environmental conditions.

Chemical Structure and Composition

Parylene coatings consist of a polymer form of para-xylylene with a linear, highly crystalline structure that provides excellent chemical inertness and moisture resistance. Polyimide coatings feature aromatic polyimide compounds characterized by imide linkages (-CO-N-CO-) in the backbone, offering exceptional thermal stability and chemical resistance. The distinct chemical compositions influence their performance in electronics and medical device protection applications.

Key Properties Overview

Parylene coatings offer exceptional conformality, chemical resistance, and excellent dielectric properties, making them ideal for protecting sensitive electronic components and medical devices. Polyimide coatings provide high thermal stability, mechanical strength, and flexibility, which are essential for applications in flexible circuits and high-temperature environments. Both materials exhibit strong moisture resistance, but Parylene's ultra-thin, pinhole-free coating surpasses Polyimide in creating hermetic barriers.

Application Methods and Processes

Parylene coating is applied through a vapor deposition process that ensures a uniform, pinhole-free conformal layer ideal for intricate electronic components, while polyimide coating is typically applied via spin coating or dip coating techniques followed by curing at high temperatures to form a durable film. The vapor deposition method for Parylene requires a vacuum chamber to polymerize the monomer directly onto substrates, providing excellent moisture and chemical resistance without adding significant weight. Polyimide's application processes allow for precise thickness control and flexibility, making it suitable for flexible circuits and insulation in harsh environments, so selecting the right method depends on your project's performance and environmental needs.

Electrical Insulation Capabilities

Parylene coating provides superior electrical insulation due to its excellent dielectric properties and uniform, pinhole-free coverage, effectively preventing moisture and contaminants from compromising sensitive electronic components. Polyimide coatings offer robust thermal stability and mechanical strength but may exhibit higher dielectric constants and less uniformity in thin-film applications compared to Parylene. For high-performance electronic insulation where moisture resistance and dielectric reliability are critical, Parylene is often the preferred choice over Polyimide.

Thermal Stability Comparison

Parylene coatings exhibit excellent thermal stability with continuous service temperatures up to 290degC, making them suitable for high-temperature applications. Polyimide coatings, in contrast, can endure much higher temperatures, often exceeding 400degC, which is ideal for extreme thermal environments. The choice between Parylene and Polyimide depends on the specific thermal requirements and operating conditions of the application.

Chemical and Moisture Resistance

Parylene coating offers superior chemical resistance and exceptional moisture barrier properties, making it ideal for protecting sensitive electronic components in harsh environments. Polyimide coating also provides strong chemical resistance and thermal stability but is generally more permeable to moisture compared to Parylene. The choice between Parylene and Polyimide depends on the specific application requirements for chemical exposure and moisture protection.

Biocompatibility and Medical Uses

Parylene coatings exhibit superior biocompatibility due to their chemical inertness, often used in implantable medical devices such as pacemakers and neural probes, ensuring minimal tissue reaction. Polyimide coatings, while offering excellent thermal stability and mechanical strength, have moderate biocompatibility suitable for flexible medical electronics like biosensors and catheter components. Your choice between Parylene and Polyimide should consider specific medical application requirements, balancing biocompatibility and mechanical properties.

Cost and Scalability Considerations

Parylene coating involves a vapor deposition process that typically results in higher initial costs due to specialized equipment and slower throughput but offers superior uniformity and moisture barrier properties. Polyimide coating provides a more cost-effective solution with scalable application methods such as spin coating and screen printing, allowing for faster production cycles in large-volume manufacturing. Considering total cost of ownership and production scale, polyimide is often favored for high-volume electronics, while parylene suits high-reliability, low-volume applications despite its premium pricing.

Choosing the Right Coating for Your Application

Parylene offers exceptional moisture and chemical resistance with a uniform, pinhole-free conformal coating ideal for sensitive electronics and medical devices, whereas Polyimide provides high thermal stability and mechanical strength suited for flexible circuits and high-temperature environments. Selecting the right coating depends on specific application requirements such as operating temperature, chemical exposure, flexibility, and electrical insulation needs. For environments demanding ultra-thin, transparent, and biocompatible protection, Parylene stands out, while Polyimide excels in durability under thermal stress and mechanical wear.

Parylene vs Polyimide coating Infographic

electrown.com

electrown.com