Aluminum Nitride (AlN) offers superior thermal conductivity and electrical insulation compared to Aluminum Oxide (Al2O3), making it ideal for high-performance electronic substrates and heat dissipation applications. Explore the article to understand which material best suits Your specific needs and how their properties impact industrial uses.

Table of Comparison

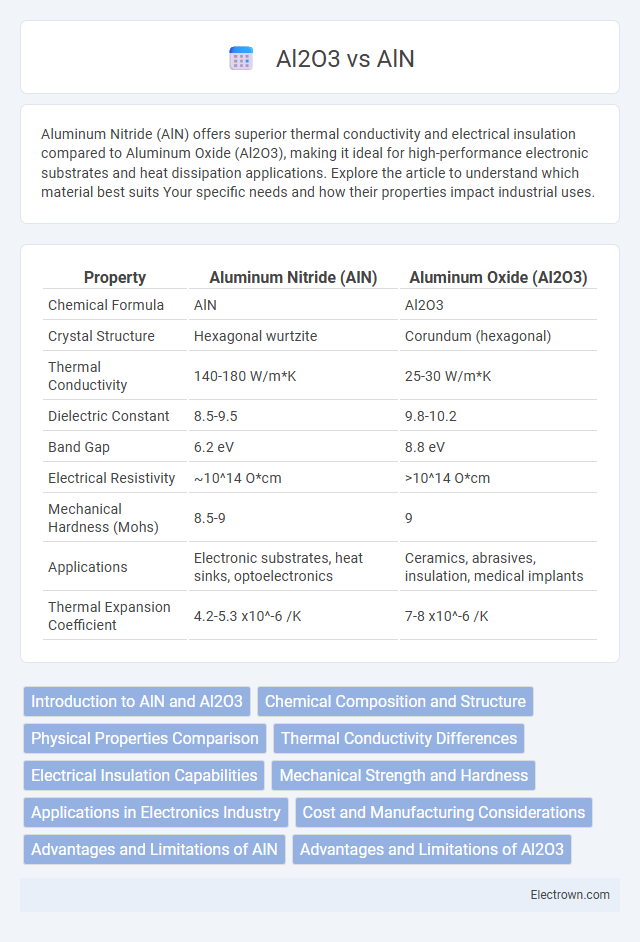

| Property | Aluminum Nitride (AlN) | Aluminum Oxide (Al2O3) |

|---|---|---|

| Chemical Formula | AlN | Al2O3 |

| Crystal Structure | Hexagonal wurtzite | Corundum (hexagonal) |

| Thermal Conductivity | 140-180 W/m*K | 25-30 W/m*K |

| Dielectric Constant | 8.5-9.5 | 9.8-10.2 |

| Band Gap | 6.2 eV | 8.8 eV |

| Electrical Resistivity | ~10^14 O*cm | >10^14 O*cm |

| Mechanical Hardness (Mohs) | 8.5-9 | 9 |

| Applications | Electronic substrates, heat sinks, optoelectronics | Ceramics, abrasives, insulation, medical implants |

| Thermal Expansion Coefficient | 4.2-5.3 x10^-6 /K | 7-8 x10^-6 /K |

Introduction to AlN and Al2O3

Aluminum Nitride (AlN) is a ceramic material known for its high thermal conductivity and electrical insulation properties, making it ideal for electronic substrates and heat sinks. Aluminum Oxide (Al2O3), or alumina, is a widely used ceramic characterized by excellent hardness, chemical stability, and electrical insulation, commonly found in cutting tools, wear-resistant applications, and insulators. Both materials serve critical roles in industrial, electronic, and thermal management applications due to their unique combinations of mechanical and thermal properties.

Chemical Composition and Structure

AlN (Aluminum Nitride) consists of aluminum and nitrogen atoms arranged in a hexagonal wurtzite crystal structure, providing high thermal conductivity and electrical insulation. Al2O3 (Aluminum Oxide), also known as alumina, is composed of aluminum and oxygen atoms forming a dense corundum crystal structure, known for its excellent hardness and chemical stability. The distinct chemical bonding in AlN results in polar covalent characteristics, while Al2O3 exhibits strong ionic and covalent bonding, influencing their respective physical and chemical properties.

Physical Properties Comparison

Aluminum Nitride (AlN) exhibits a high thermal conductivity of around 140-180 W/m*K, significantly outperforming Aluminum Oxide (Al2O3), which typically ranges between 20-30 W/m*K. AlN also has a lower dielectric constant (~8.5) compared to Al2O3 (~9-10), making it more suitable for high-frequency electronic applications. Your choice depends on whether thermal management or electrical insulation is the priority, as AlN offers superior heat dissipation while Al2O3 provides excellent hardness and chemical stability.

Thermal Conductivity Differences

Aluminum Nitride (AlN) exhibits a significantly higher thermal conductivity, typically around 140-180 W/m*K, compared to Aluminum Oxide (Al2O3), which ranges from 20-35 W/m*K. This makes AlN a superior choice for applications requiring efficient heat dissipation, such as in high-power electronics and LED substrates. Your devices benefit from AlN's enhanced thermal management, reducing the risk of overheating and improving overall performance.

Electrical Insulation Capabilities

AlN (Aluminum Nitride) and Al2O3 (Aluminum Oxide) both serve as excellent electrical insulators, but AlN offers superior thermal conductivity while maintaining high electrical resistance, making it ideal for high-power electronics. Al2O3 exhibits higher dielectric strength, providing better insulation in applications requiring robust voltage endurance. Your choice depends on balancing thermal management with insulation demands in electronic component design.

Mechanical Strength and Hardness

Aluminum nitride (AlN) exhibits superior mechanical strength with a tensile strength typically around 200 MPa, making it suitable for applications requiring high durability under mechanical stress. Its hardness measures roughly 11 GPa on the Vickers scale, offering significant resistance to wear and deformation. In comparison, aluminum oxide (Al2O3) shows higher hardness values, often exceeding 20 GPa, but generally has lower tensile strength, around 150 MPa, making it more brittle despite its excellent abrasion resistance.

Applications in Electronics Industry

Aluminum Nitride (AlN) offers superior thermal conductivity and electrical insulation, making it ideal for heat dissipation in power electronics and LED substrates. Aluminum Oxide (Al2O3), renowned for its excellent dielectric properties and mechanical strength, is commonly used in insulating substrates and protective coatings in electronic devices. Your choice between AlN and Al2O3 depends on the balance between thermal management needs and insulation requirements in your specific electronic application.

Cost and Manufacturing Considerations

AlN (Aluminum Nitride) typically incurs higher production costs compared to Al2O3 (Aluminum Oxide) due to its complex synthesis processes such as chemical vapor deposition and the need for high-temperature environments. Al2O3 benefits from well-established, large-scale manufacturing techniques like sintering and extrusion, making it more cost-effective and widely available. The choice between AlN and Al2O3 often hinges on balancing cost constraints with specific performance requirements in thermal conductivity and electrical insulation.

Advantages and Limitations of AlN

Aluminum Nitride (AlN) offers superior thermal conductivity of around 140-180 W/mK compared to Aluminum Oxide (Al2O3), which typically ranges from 20-30 W/mK, making AlN ideal for high-performance electronic substrates and heat dissipation applications. AlN exhibits excellent electrical insulation properties alongside low thermal expansion that closely matches silicon, reducing device stress and enhancing reliability in semiconductor packaging. However, its higher production cost and sensitivity to moisture limit widespread use, whereas Al2O3 provides better mechanical strength and chemical stability at a more affordable price point.

Advantages and Limitations of Al2O3

Al2O3 (aluminum oxide) offers excellent thermal stability, high hardness, and outstanding electrical insulation, making it ideal for electronic substrates and protective coatings. Its limitations include lower thermal conductivity compared to AlN (aluminum nitride), which restricts its use in high-power or high-frequency electronic applications where efficient heat dissipation is critical. Despite this, Al2O3 remains cost-effective and chemically inert, providing superior corrosion resistance in harsh environments.

AlN vs Al2O3 Infographic

electrown.com

electrown.com