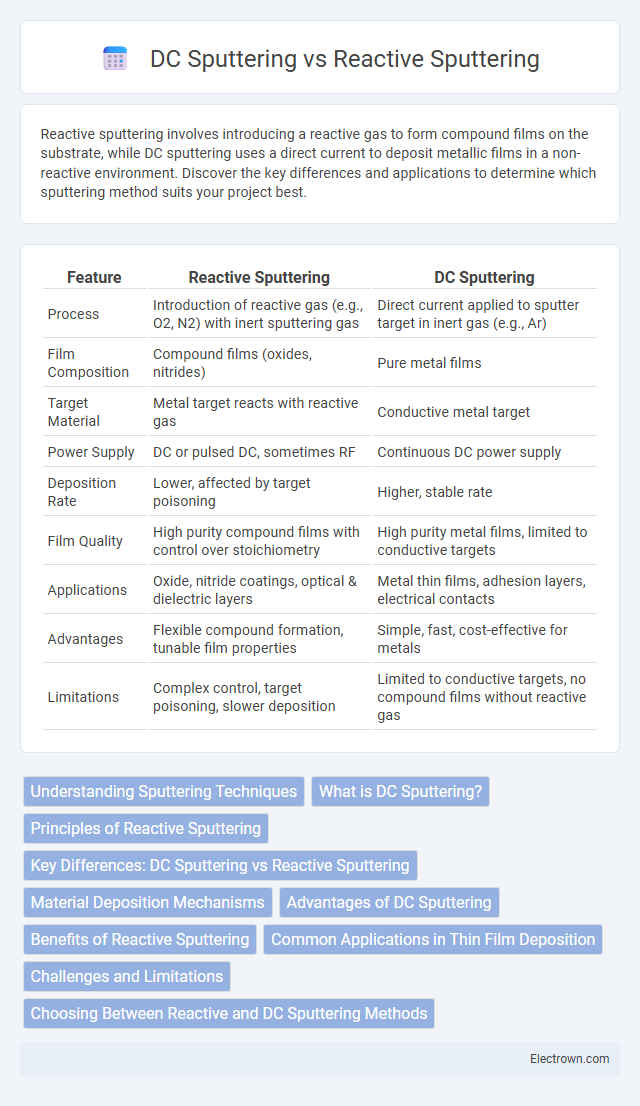

Reactive sputtering involves introducing a reactive gas to form compound films on the substrate, while DC sputtering uses a direct current to deposit metallic films in a non-reactive environment. Discover the key differences and applications to determine which sputtering method suits your project best.

Table of Comparison

| Feature | Reactive Sputtering | DC Sputtering |

|---|---|---|

| Process | Introduction of reactive gas (e.g., O2, N2) with inert sputtering gas | Direct current applied to sputter target in inert gas (e.g., Ar) |

| Film Composition | Compound films (oxides, nitrides) | Pure metal films |

| Target Material | Metal target reacts with reactive gas | Conductive metal target |

| Power Supply | DC or pulsed DC, sometimes RF | Continuous DC power supply |

| Deposition Rate | Lower, affected by target poisoning | Higher, stable rate |

| Film Quality | High purity compound films with control over stoichiometry | High purity metal films, limited to conductive targets |

| Applications | Oxide, nitride coatings, optical & dielectric layers | Metal thin films, adhesion layers, electrical contacts |

| Advantages | Flexible compound formation, tunable film properties | Simple, fast, cost-effective for metals |

| Limitations | Complex control, target poisoning, slower deposition | Limited to conductive targets, no compound films without reactive gas |

Understanding Sputtering Techniques

Reactive sputtering involves introducing a reactive gas, such as oxygen or nitrogen, into the sputtering chamber to form compound thin films like oxides or nitrides, enhancing film properties. DC sputtering uses a constant direct current to sputter conductive target materials, ideal for depositing pure metal films with high deposition rates and uniformity. Understanding these sputtering techniques helps you select the optimal process for your thin film application based on material type and desired film characteristics.

What is DC Sputtering?

DC sputtering is a physical vapor deposition (PVD) technique where a direct current power source creates a plasma to eject atoms from a target material onto a substrate. It is commonly used for conductive materials and offers high deposition rates with excellent film uniformity. Your choice between DC and reactive sputtering depends on the desired film composition, as reactive sputtering introduces a reactive gas to form compound films, while DC sputtering mainly deposits pure metal films.

Principles of Reactive Sputtering

Reactive sputtering involves introducing a reactive gas, such as oxygen or nitrogen, into the sputtering chamber to form compound films on the substrate by chemically reacting with the target material. This process allows the deposition of compound thin films like oxides, nitrides, or carbides, which differ from pure elemental films produced by DC sputtering that uses an inert gas like argon. Control over parameters such as gas flow rates, pressure, and target power is critical in reactive sputtering to maintain film stoichiometry and achieve desired material properties.

Key Differences: DC Sputtering vs Reactive Sputtering

DC sputtering utilizes a constant direct current to eject atoms from a pure metal target, producing thin films of the target material. Reactive sputtering introduces a reactive gas, such as oxygen or nitrogen, which combines with the sputtered atoms to form compound thin films like oxides or nitrides. The primary difference lies in the film composition control: DC sputtering deposits elemental films, while reactive sputtering enables the synthesis of compound materials through in-situ chemical reactions.

Material Deposition Mechanisms

Reactive sputtering involves the introduction of reactive gases such as oxygen or nitrogen into the plasma during the sputtering process, enabling the formation of compound films like oxides or nitrides through chemical reactions on the substrate surface. DC sputtering uses a direct current power source to eject atoms from a target material, depositing them directly onto the substrate without chemical modification, making it suitable primarily for metallic film deposition. The material deposition mechanism in reactive sputtering is dominated by both physical sputtering and chemical reactions, while DC sputtering relies solely on physical sputtering to build thin films.

Advantages of DC Sputtering

DC sputtering offers high deposition rates and excellent control over film thickness, making it ideal for conductive materials. This method provides stable plasma conditions, resulting in uniform coatings with superior adhesion and density. It is also cost-effective and simpler to implement compared to reactive sputtering, which often requires complex gas mixtures and process control.

Benefits of Reactive Sputtering

Reactive sputtering enables precise control over film composition by introducing reactive gases, leading to the deposition of compound films such as oxides, nitrides, and carbides with tailored properties. This method enhances film adhesion, uniformity, and stoichiometry, making it ideal for semiconductor, optical, and corrosion-resistant coatings. Compared to DC sputtering, reactive sputtering offers superior versatility in producing complex materials with improved chemical and mechanical stability.

Common Applications in Thin Film Deposition

Reactive sputtering is widely used for depositing compound thin films such as oxides, nitrides, and carbides in applications like semiconductor devices, solar cells, and hard coatings. DC sputtering primarily deposits metallic thin films, making it ideal for conductive layers in microelectronics, interconnects, and reflective coatings. The choice between reactive and DC sputtering depends on the desired film composition, electrical properties, and adhesion requirements in thin film deposition processes.

Challenges and Limitations

Reactive sputtering faces challenges such as target poisoning, where the reactive gas forms a compound layer on the target surface, leading to instability in deposition rates and film composition. DC sputtering is limited to conductive targets, restricting its use with insulating materials, and often suffers from arc formation that can damage the substrate and reduce film quality. Your choice between these methods must consider these limitations based on the material and film properties required for your application.

Choosing Between Reactive and DC Sputtering Methods

Choosing between reactive sputtering and DC sputtering depends on the desired film composition and application requirements. Reactive sputtering introduces a reactive gas to form compound films such as oxides or nitrides, enabling precise control over film stoichiometry, while DC sputtering is ideal for depositing pure metallic layers with high deposition rates. Your specific coating needs and material compatibility will determine the most effective sputtering technique for optimal thin film performance.

reactive sputtering vs DC sputtering Infographic

electrown.com

electrown.com