SMD resistors offer a compact design and are ideal for automated surface-mount technology, providing higher circuit density and improved performance in modern electronic devices. Explore the rest of the article to understand how these differences impact your choice between SMD and through-hole resistors.

Table of Comparison

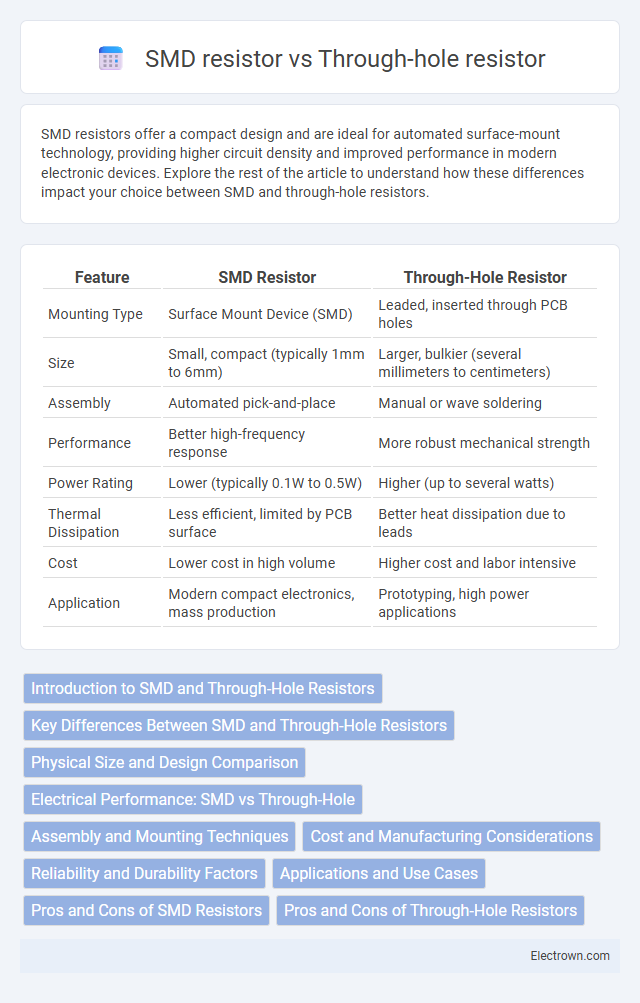

| Feature | SMD Resistor | Through-Hole Resistor |

|---|---|---|

| Mounting Type | Surface Mount Device (SMD) | Leaded, inserted through PCB holes |

| Size | Small, compact (typically 1mm to 6mm) | Larger, bulkier (several millimeters to centimeters) |

| Assembly | Automated pick-and-place | Manual or wave soldering |

| Performance | Better high-frequency response | More robust mechanical strength |

| Power Rating | Lower (typically 0.1W to 0.5W) | Higher (up to several watts) |

| Thermal Dissipation | Less efficient, limited by PCB surface | Better heat dissipation due to leads |

| Cost | Lower cost in high volume | Higher cost and labor intensive |

| Application | Modern compact electronics, mass production | Prototyping, high power applications |

Introduction to SMD and Through-Hole Resistors

Surface-mount device (SMD) resistors and through-hole resistors differ primarily in their mounting techniques: SMD resistors are compact components soldered directly onto the surface of printed circuit boards (PCBs), offering higher component density and improved performance at high frequencies. Through-hole resistors have leads that pass through drilled holes in the PCB and are soldered on the opposite side, providing stronger mechanical bonds suitable for prototype and high-stress environments. SMD resistors enable automated assembly processes, while through-hole resistors are preferred for ease of manual handling and repair.

Key Differences Between SMD and Through-Hole Resistors

SMD resistors are compact, surface-mounted components ideal for automated PCB assembly, offering high-density circuit designs and improved performance at high frequencies. Through-hole resistors feature leads inserted into drilled holes on the PCB, providing stronger mechanical bonds and ease of manual prototyping or repair. Your selection depends on space constraints, manufacturing methods, and durability requirements in your electronic projects.

Physical Size and Design Comparison

SMD resistors exhibit a significantly smaller physical size than through-hole resistors, measuring typically between 0.6 mm to 3.2 mm in length, enabling high-density circuit board designs. Their compact, rectangular chip form contrasts with the larger cylindrical body and extended leads of through-hole resistors, which can range from 3 mm to 10 mm or more. This size difference influences PCB layout complexity and assembly processes, with SMD resistors favoring automated surface-mount technology and through-hole components supporting manual or wave soldering applications.

Electrical Performance: SMD vs Through-Hole

SMD resistors offer superior high-frequency performance and lower parasitic inductance compared to through-hole resistors, making them ideal for compact, high-speed circuits. Through-hole resistors typically provide better power dissipation and mechanical strength but exhibit higher lead inductance, affecting signal integrity in fast switching applications. Your choice between SMD and through-hole resistors should consider the electrical performance requirements of your specific circuit design.

Assembly and Mounting Techniques

Surface-mount device (SMD) resistors are mounted directly onto the surface of printed circuit boards using automated pick-and-place machines, facilitating high-speed, precise placements suitable for compact and mass production environments. Through-hole resistors require insertion into pre-drilled holes and are typically secured by soldering on the opposite side of the board, providing stronger mechanical bonds ideal for components subjected to mechanical stress. SMD assembly reduces board space and enhances circuit density, while through-hole techniques offer easier manual assembly and prototyping flexibility.

Cost and Manufacturing Considerations

SMD resistors typically offer lower manufacturing costs due to automated assembly processes and smaller package sizes, enabling higher production speeds and reduced material usage. Through-hole resistors involve higher labor costs and slower assembly times as they require manual or selective soldering techniques on PCBs. Cost efficiency in SMD resistors is favored in high-volume manufacturing, whereas through-hole components may remain viable for prototyping or applications needing greater mechanical stability.

Reliability and Durability Factors

SMD resistors offer enhanced reliability and durability due to their smaller size and surface-mount technology, which reduces mechanical stress and improves thermal performance under high-frequency conditions. Through-hole resistors, while generally more robust in high-vibration environments, are prone to solder joint fatigue and can suffer from mechanical strain over time. Choosing between SMD and through-hole resistors depends on your application's tolerance for vibration, thermal cycles, and long-term environmental exposure.

Applications and Use Cases

SMD resistors are ideal for compact electronic devices such as smartphones, laptops, and wearable technology due to their small size and ease of automated assembly, enhancing circuit density and performance. Through-hole resistors are preferred in applications requiring robust mechanical strength, like industrial equipment, power supplies, and prototyping, where durability and ease of manual soldering are critical. Choosing between SMD and through-hole resistors depends on your project's size constraints, manufacturing process, and environment for optimal reliability and functionality.

Pros and Cons of SMD Resistors

SMD resistors offer significant advantages such as smaller size, allowing for high-density circuit board designs and enabling automated assembly processes that increase manufacturing efficiency. Their low inductance and capacitance improve high-frequency performance, making them ideal for advanced electronics. However, drawbacks include difficulty in manual handling and repair, higher initial equipment costs, and limited power dissipation compared to larger through-hole resistors.

Pros and Cons of Through-Hole Resistors

Through-hole resistors offer robust mechanical strength and easier prototyping due to their larger size and leaded construction, which facilitates manual soldering and component replacement. Their primary drawbacks include limited suitability for high-density circuit boards and slower automated assembly processes compared to surface-mount device (SMD) resistors. Through-hole components are preferred in applications requiring strong mechanical bonds and high power dissipation but are less optimal for compact, high-speed electronics where space and weight savings are critical.

SMD resistor vs Through-hole resistor Infographic

electrown.com

electrown.com