Green PCB soldermask offers superior visibility of traces and is the industry standard due to its proven reliability and availability, whereas Blue PCB soldermask provides a unique aesthetic and better contrast for inspection under certain lighting conditions. Discover which soldermask is best suited for Your project's performance and appearance by reading the rest of the article.

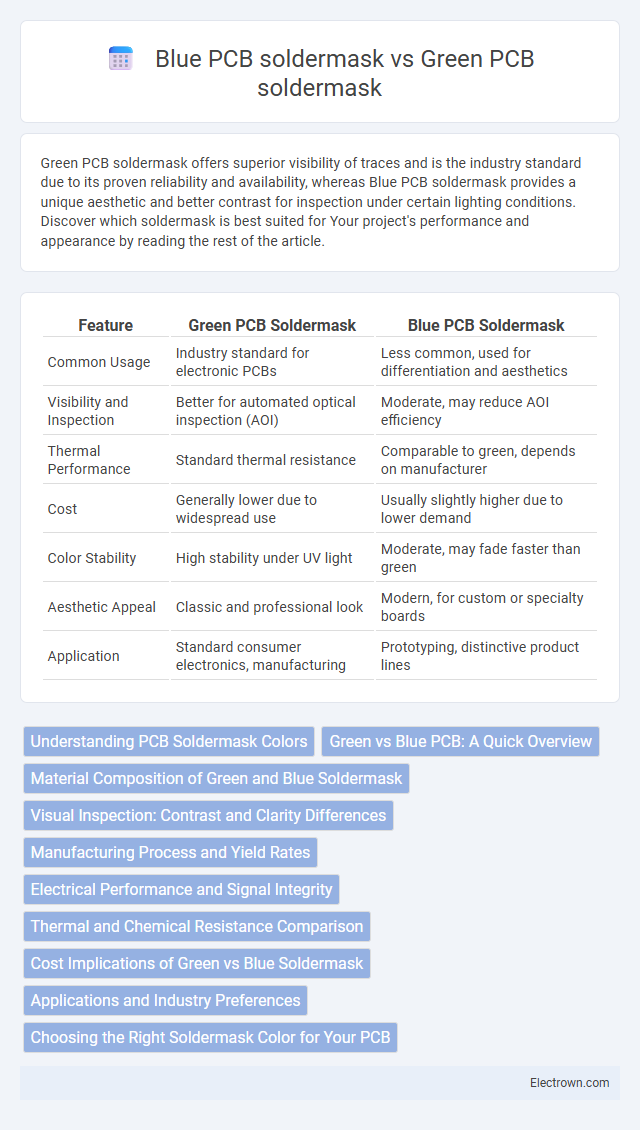

Table of Comparison

| Feature | Green PCB Soldermask | Blue PCB Soldermask |

|---|---|---|

| Common Usage | Industry standard for electronic PCBs | Less common, used for differentiation and aesthetics |

| Visibility and Inspection | Better for automated optical inspection (AOI) | Moderate, may reduce AOI efficiency |

| Thermal Performance | Standard thermal resistance | Comparable to green, depends on manufacturer |

| Cost | Generally lower due to widespread use | Usually slightly higher due to lower demand |

| Color Stability | High stability under UV light | Moderate, may fade faster than green |

| Aesthetic Appeal | Classic and professional look | Modern, for custom or specialty boards |

| Application | Standard consumer electronics, manufacturing | Prototyping, distinctive product lines |

Understanding PCB Soldermask Colors

Green PCB soldermask remains the industry standard due to its superior visibility and inspection contrast, enhancing defect detection and assembly accuracy. Blue PCB soldermask offers improved aesthetics and is favored for custom or high-end projects, though it may slightly reduce contrast under inspection lighting. Choosing between green and blue soldermasks depends on balancing visibility requirements, cost considerations, and design preferences for specific PCB applications.

Green vs Blue PCB: A Quick Overview

Green PCB soldermask offers industry-standard visibility and contrast, making it easier to inspect and repair circuits compared to Blue PCB soldermask, which provides a sleek, modern aesthetic favored in specialized applications. The green color enhances solder joint inspection under various lighting conditions, while blue tends to absorb more light, potentially complicating visual inspections. Your choice between green and blue PCB soldermask should balance functional requirements with design preferences for optimal performance and appearance.

Material Composition of Green and Blue Soldermask

Green and blue PCB soldermasks primarily use epoxy-based materials, but their pigment additives differ, impacting UV resistance and thermal stability. The green soldermask contains chromophore compounds providing excellent contrast for automated optical inspection, while the blue variant incorporates cobalt or copper phthalocyanine pigments that enhance aesthetic appeal and slightly alter curing characteristics. Your choice between green and blue soldermask should consider these material properties for optimal performance in specific electronic applications.

Visual Inspection: Contrast and Clarity Differences

Green PCB soldermask offers higher contrast against white silkscreen and metal traces, enhancing visual inspection accuracy by making component markings and defects easier to identify. Blue PCB soldermask provides good clarity but can sometimes cause lower contrast with certain component colors, potentially requiring closer examination during quality checks. Your choice between green and blue soldermask can impact inspection efficiency by influencing the visibility of critical details on the PCB surface.

Manufacturing Process and Yield Rates

Green PCB soldermask benefits from a well-established manufacturing process with higher yield rates due to its widespread industry adoption and optimized curing techniques. Blue PCB soldermask, while providing aesthetically distinct results, often involves slightly adjusted processing parameters that can impact yield rates depending on the manufacturer's experience with this color variant. Your choice between green and blue soldermask should consider the trade-off between manufacturing efficiency and desired visual outcomes.

Electrical Performance and Signal Integrity

Green PCB soldermask typically offers superior electrical performance and signal integrity due to its proven material composition and lower dielectric constant, which minimizes signal loss and crosstalk. Blue PCB soldermasks, while visually distinct, may have slightly higher dielectric constants that can affect high-frequency signal transmission and increase impedance variations. Choosing the right soldermask color, particularly green, can enhance your PCB's reliability in high-speed and sensitive electronic applications.

Thermal and Chemical Resistance Comparison

Green PCB soldermask typically exhibits superior thermal resistance, withstanding temperatures up to 260degC during the soldering process, whereas blue PCB soldermask may have slightly lower thermal thresholds, often around 250degC. Chemically, green soldermask offers enhanced resistance to flux, cleaning agents, and solvents commonly used in PCB assembly, reducing the risk of corrosion and degradation. These differences make green soldermask more suitable for high-thermal and chemically demanding environments compared to blue soldermask options.

Cost Implications of Green vs Blue Soldermask

Green soldermask is typically more cost-effective due to its widespread use and established manufacturing processes, resulting in lower production expenses. Blue soldermask, while offering aesthetic appeal and improved contrast for inspection, often incurs higher costs because of less common usage and specialized pigment formulations. Your choice between green and blue soldermask should consider the budget constraints and the specific requirements for visual inspection and product differentiation.

Applications and Industry Preferences

Green PCB soldermask is widely preferred in electronics manufacturing due to its excellent visibility for inspection and strong contrast with component markings, making it ideal for consumer electronics, automotive, and telecommunications industries. Blue PCB soldermask, favored in aerospace and defense sectors, offers enhanced optical clarity and reduced eye strain during assembly and testing in specialized applications requiring precise visual inspection. Industry preferences lean towards green for cost-effectiveness and established standards, while blue caters to niche markets demanding higher inspection accuracy and aesthetic differentiation.

Choosing the Right Soldermask Color for Your PCB

Choosing the right soldermask color for your PCB impacts not only its aesthetic appeal but also functionality and inspection efficiency. Green soldermask offers industry-standard visibility for automated optical inspection and is widely available with proven reliability, while blue soldermask enhances contrast for easier manual inspection and offers a modern visual appeal. Your decision should consider factors such as optical clarity, manufacturing standards, and the specific inspection methods used in your production process.

Green PCB vs Blue PCB soldermask Infographic

electrown.com

electrown.com