Bulk heterojunction solar cells feature an interpenetrating network of donor and acceptor materials, enhancing charge separation and transport compared to the distinct layered structure of planar heterojunctions, which limits interface area but offers simpler fabrication. Understanding these differences can help optimize Your device design for better efficiency, so continue reading to explore their comparative advantages and applications.

Table of Comparison

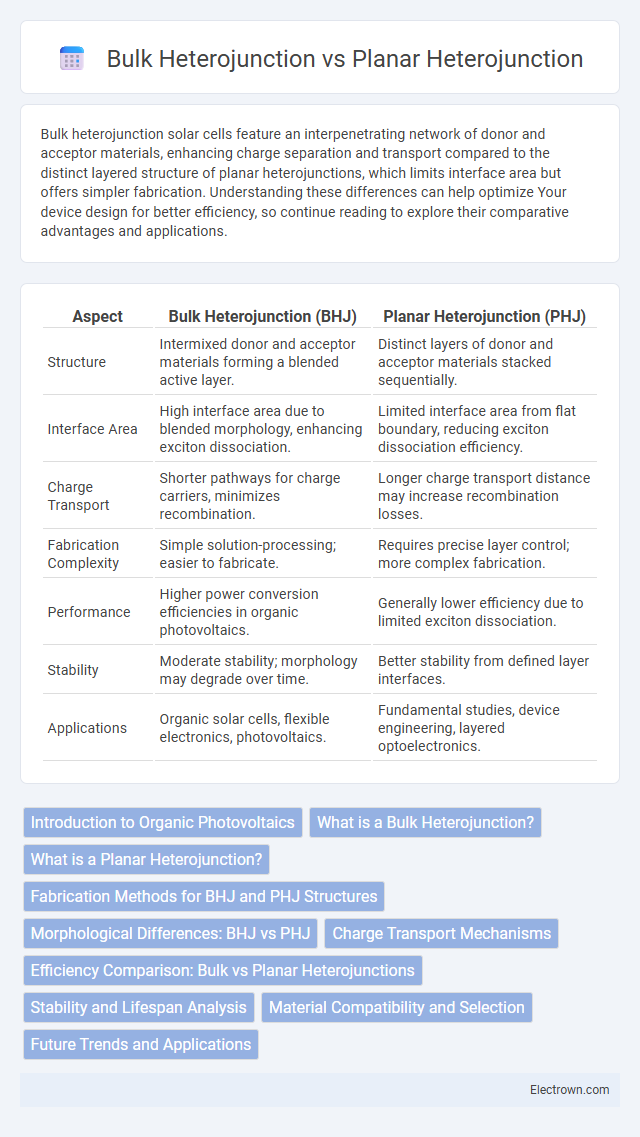

| Aspect | Bulk Heterojunction (BHJ) | Planar Heterojunction (PHJ) |

|---|---|---|

| Structure | Intermixed donor and acceptor materials forming a blended active layer. | Distinct layers of donor and acceptor materials stacked sequentially. |

| Interface Area | High interface area due to blended morphology, enhancing exciton dissociation. | Limited interface area from flat boundary, reducing exciton dissociation efficiency. |

| Charge Transport | Shorter pathways for charge carriers, minimizes recombination. | Longer charge transport distance may increase recombination losses. |

| Fabrication Complexity | Simple solution-processing; easier to fabricate. | Requires precise layer control; more complex fabrication. |

| Performance | Higher power conversion efficiencies in organic photovoltaics. | Generally lower efficiency due to limited exciton dissociation. |

| Stability | Moderate stability; morphology may degrade over time. | Better stability from defined layer interfaces. |

| Applications | Organic solar cells, flexible electronics, photovoltaics. | Fundamental studies, device engineering, layered optoelectronics. |

Introduction to Organic Photovoltaics

Organic photovoltaics (OPVs) utilize semiconducting polymers to convert sunlight into electricity, with bulk heterojunction (BHJ) and planar heterojunction (PHJ) being the primary device architectures. BHJ blends donor and acceptor materials within the active layer, maximizing interface area for exciton dissociation and improving charge transport, while PHJ features distinct layered donor and acceptor materials with limited interface contact. Your choice between these architectures impacts power conversion efficiency, stability, and fabrication complexity in organic solar cells.

What is a Bulk Heterojunction?

A Bulk Heterojunction (BHJ) is an interpenetrating network of electron-donating and electron-accepting materials used in organic photovoltaic cells to enhance charge separation and transport. Unlike planar heterojunctions, BHJs offer a larger interface area between donor and acceptor phases, improving exciton dissociation efficiency and overall device performance. This morphology enables more efficient photocurrent generation by facilitating continuous pathways for both electrons and holes within the active layer.

What is a Planar Heterojunction?

A planar heterojunction is a type of interface in organic solar cells where two distinct semiconductor layers--one donor and one acceptor--are stacked in a flat, well-defined boundary, facilitating charge separation. This structure contrasts with a bulk heterojunction, which features an interpenetrating network of donor and acceptor materials on a nanoscale, enhancing exciton dissociation. Your choice between planar and bulk heterojunctions impacts device efficiency, as the planar design offers easier fabrication and controlled morphology but may limit exciton diffusion compared to bulk heterojunctions.

Fabrication Methods for BHJ and PHJ Structures

Bulk heterojunction (BHJ) fabrication involves blending donor and acceptor materials into a single active layer using solution processing techniques like spin coating or inkjet printing, enabling a nanoscale interpenetrating network essential for efficient charge separation. Planar heterojunction (PHJ) structures are fabricated by sequentially depositing distinct donor and acceptor layers through methods such as thermal evaporation or layer-by-layer spin coating, resulting in a sharp interface that facilitates exciton dissociation. Your choice of fabrication method directly impacts the morphology and performance of organic photovoltaic devices.

Morphological Differences: BHJ vs PHJ

Bulk heterojunction (BHJ) solar cells feature an interpenetrating network of donor and acceptor materials, creating a large interface area that enhances exciton dissociation and charge transport. Planar heterojunction (PHJ) devices have a distinct, flat interface between the donor and acceptor layers, resulting in limited exciton diffusion and potentially lower charge separation efficiency. Your choice between BHJ and PHJ morphologies depends on balancing interface area with charge carrier mobility for optimized device performance.

Charge Transport Mechanisms

Bulk heterojunction solar cells feature an interpenetrating network of donor and acceptor materials, which facilitates efficient exciton dissociation and short charge transport pathways, enhancing charge collection. Planar heterojunction devices rely on a distinct layered structure, where excitons must diffuse to the interface for separation, often leading to limited charge mobility and higher recombination rates. Understanding these charge transport mechanisms can help optimize your device architecture for improved photovoltaic performance.

Efficiency Comparison: Bulk vs Planar Heterojunctions

Bulk heterojunction solar cells typically achieve higher power conversion efficiencies than planar heterojunctions due to their larger donor-acceptor interface area, which facilitates more efficient exciton dissociation and charge transport. Planar heterojunctions suffer from limited interface contact, resulting in lower exciton separation rates and reduced photocurrent generation. To maximize your device efficiency, bulk heterojunction architectures are generally preferred in organic photovoltaic applications.

Stability and Lifespan Analysis

Bulk heterojunction solar cells exhibit enhanced stability due to their interpenetrating network that reduces exciton recombination and improves charge transport, resulting in longer device lifespan under operational stress. Planar heterojunctions often face stability challenges from interface degradation and phase separation, leading to faster performance decline. Advanced encapsulation techniques and material engineering continue to improve the durability of bulk heterojunction architectures compared to planar counterparts.

Material Compatibility and Selection

Bulk heterojunction solar cells offer greater material compatibility by blending donor and acceptor materials into a single active layer, enabling enhanced exciton dissociation and charge transport. Planar heterojunction structures require precise selection of materials with well-aligned energy levels and excellent interfacial properties to ensure efficient charge separation across a sharp interface. Your choice depends on balancing material miscibility and electronic properties to optimize device performance in specific applications.

Future Trends and Applications

Bulk heterojunction solar cells dominate future renewable energy trends due to their superior charge separation efficiency and flexibility in organic photovoltaic devices. Planar heterojunctions, while offering better layer control and stability, face scalability challenges but hold potential in niche applications like tandem solar cells and specialized photodetectors. Your choice of heterojunction technology will influence the efficiency and application scope in emerging optoelectronic devices, including wearable electronics and large-area solar panels.

bulk heterojunction vs planar heterojunction Infographic

electrown.com

electrown.com