Silicon Carbide (SiC) wafers offer superior thermal conductivity and high electric field breakdown voltage, making them ideal for high-power electronics, while sapphire wafers excel in optical applications due to their excellent transparency and chemical stability. Discover how choosing between SiC and sapphire wafers can impact your semiconductor or optoelectronic projects by reading the full article.

Table of Comparison

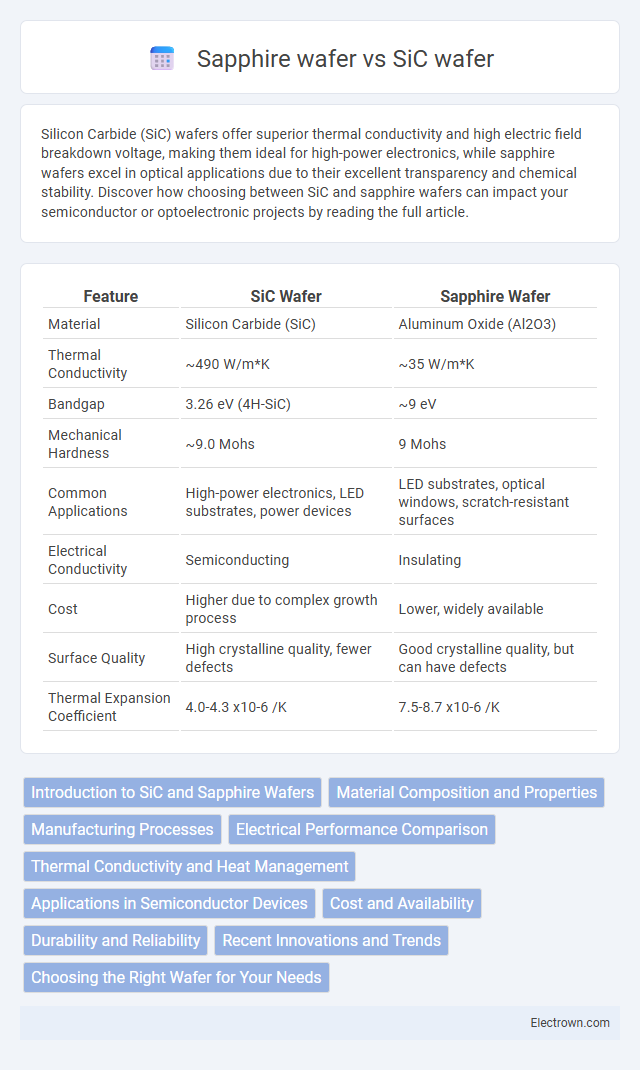

| Feature | SiC Wafer | Sapphire Wafer |

|---|---|---|

| Material | Silicon Carbide (SiC) | Aluminum Oxide (Al2O3) |

| Thermal Conductivity | ~490 W/m*K | ~35 W/m*K |

| Bandgap | 3.26 eV (4H-SiC) | ~9 eV |

| Mechanical Hardness | ~9.0 Mohs | 9 Mohs |

| Common Applications | High-power electronics, LED substrates, power devices | LED substrates, optical windows, scratch-resistant surfaces |

| Electrical Conductivity | Semiconducting | Insulating |

| Cost | Higher due to complex growth process | Lower, widely available |

| Surface Quality | High crystalline quality, fewer defects | Good crystalline quality, but can have defects |

| Thermal Expansion Coefficient | 4.0-4.3 x10-6 /K | 7.5-8.7 x10-6 /K |

Introduction to SiC and Sapphire Wafers

Silicon Carbide (SiC) wafers are semiconductor substrates known for their high thermal conductivity, wide bandgap, and robustness in high-temperature, high-power electronic applications. Sapphire wafers, made from single-crystal aluminum oxide, offer excellent optical transparency and mechanical hardness, making them ideal for LED production and optical devices. Both materials serve distinct roles in the semiconductor industry, with SiC favoring power electronics and Sapphire excelling in optoelectronics and substrates for gallium nitride (GaN) growth.

Material Composition and Properties

Silicon Carbide (SiC) wafers consist of silicon and carbon atoms forming a robust covalent bond matrix, resulting in exceptional thermal conductivity, high breakdown electric field, and superior chemical stability. Sapphire wafers are composed of crystalline aluminum oxide (Al2O3), offering excellent hardness, optical transparency, and high resistance to chemical corrosion but lower thermal conductivity than SiC. The disparity in material composition directly influences their electrical conductivity, thermal performance, and suitability for high-power and optoelectronic applications.

Manufacturing Processes

SiC wafers are manufactured using high-temperature physical vapor transport (PVT) or chemical vapor deposition (CVD), enabling precise crystal growth with minimal defects for high-power electronic applications. Sapphire wafers are primarily produced through the Kyropoulos or heat exchanger method (HEM), which melts aluminum oxide to form large single crystals suitable for LED substrates and optical devices. The manufacturing complexity and cost of SiC wafers are higher due to stringent purity and temperature requirements compared to the more established and cost-effective sapphire wafer production techniques.

Electrical Performance Comparison

Silicon carbide (SiC) wafers exhibit superior electrical performance compared to sapphire wafers due to higher electron mobility and greater breakdown electric field strength, enabling devices to operate at higher voltages and temperatures. SiC's wide bandgap of approximately 3.26 eV enhances thermal conductivity and reduces leakage current, resulting in improved efficiency for power electronics and high-frequency applications. Sapphire wafers, with a bandgap around 9.9 eV, primarily serve as insulating substrates, offering excellent isolation but limited electrical conduction capabilities relative to SiC.

Thermal Conductivity and Heat Management

Silicon Carbide (SiC) wafers exhibit significantly higher thermal conductivity, typically around 370 W/m*K, compared to Sapphire wafers, which have thermal conductivity near 35 W/m*K. This superior heat dissipation capability makes SiC wafers ideal for applications requiring efficient heat management and high-power electronic devices. Your choice of wafer material directly impacts the performance and reliability of devices operating under high thermal stress.

Applications in Semiconductor Devices

SiC wafers are widely used in power electronics and high-temperature semiconductor devices due to their excellent thermal conductivity and high breakdown voltage, making them ideal for applications like electric vehicles and power inverters. Sapphire wafers are preferred in optoelectronics and LED manufacturing because of their optical transparency and mechanical hardness, enhancing device efficiency and durability. Your choice between SiC and Sapphire wafers depends on whether your application requires high-power performance or superior optical properties.

Cost and Availability

Silicon carbide (SiC) wafers typically exhibit higher costs compared to sapphire wafers due to complex manufacturing processes and limited large-diameter substrate availability. Sapphire wafers benefit from well-established production techniques and larger-scale manufacturing, resulting in lower prices and greater availability. Industries requiring cost-effective solutions often prefer sapphire wafers, while high-performance applications justify the premium cost of SiC wafers.

Durability and Reliability

SiC wafers exhibit superior durability and reliability compared to sapphire wafers due to their exceptional hardness, thermal conductivity, and chemical stability, making them ideal for high-power and high-temperature applications. Sapphire wafers are more brittle and less efficient in dissipating heat, which can compromise long-term device performance under extreme conditions. Choosing SiC wafers enhances your product's lifespan and operational resilience in demanding environments.

Recent Innovations and Trends

Recent innovations in SiC wafer technology include enhanced crystal growth methods that improve wafer uniformity and reduce defects, significantly boosting power device performance. Sapphire wafers continue to evolve with advancements in bulk crystal growth and polishing techniques, optimizing their use in LED and semiconductor applications. Your choice between SiC and sapphire wafers should consider the latest developments tailored to high-power electronics versus optoelectronics needs.

Choosing the Right Wafer for Your Needs

SiC wafers offer superior thermal conductivity and high power handling, making them ideal for power electronics and high-frequency devices, while sapphire wafers excel in optical applications due to their exceptional transparency and chemical stability. Your choice depends on specific device requirements such as electrical performance, thermal management, or optical clarity. Carefully evaluating these factors ensures you select the wafer material that optimizes the efficiency and durability of your electronic or photonic device.

SiC wafer vs Sapphire wafer Infographic

electrown.com

electrown.com