UV curable ink offers faster drying times, eco-friendly properties, and vibrant color output compared to traditional solvent-based ink, which relies on chemical solvents that can emit harmful VOCs and require longer drying periods. Discover how choosing the right ink type can impact your printing quality, environmental footprint, and project efficiency by exploring the full article.

Table of Comparison

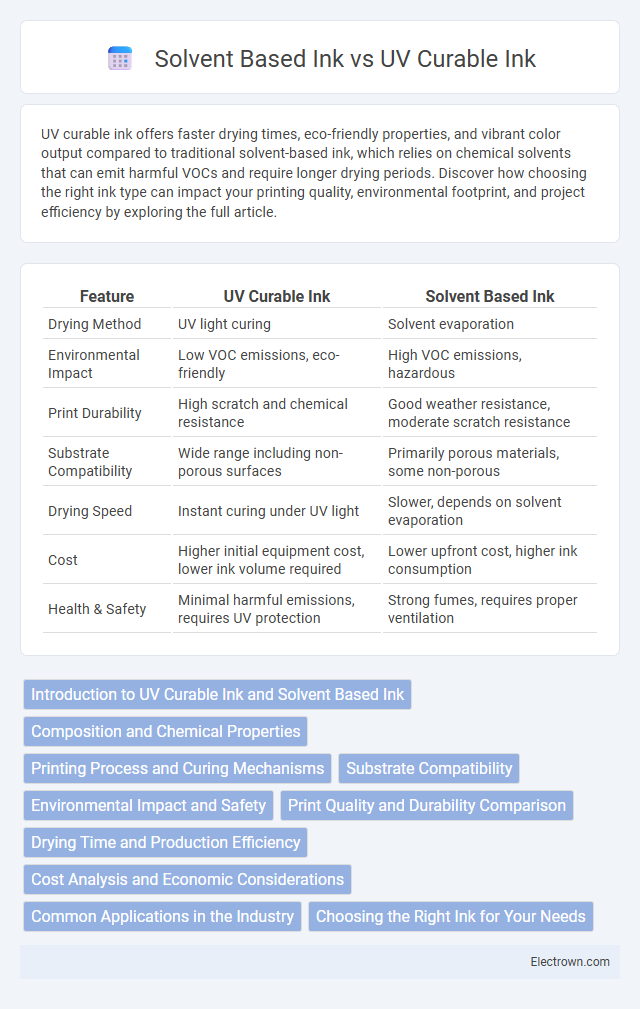

| Feature | UV Curable Ink | Solvent Based Ink |

|---|---|---|

| Drying Method | UV light curing | Solvent evaporation |

| Environmental Impact | Low VOC emissions, eco-friendly | High VOC emissions, hazardous |

| Print Durability | High scratch and chemical resistance | Good weather resistance, moderate scratch resistance |

| Substrate Compatibility | Wide range including non-porous surfaces | Primarily porous materials, some non-porous |

| Drying Speed | Instant curing under UV light | Slower, depends on solvent evaporation |

| Cost | Higher initial equipment cost, lower ink volume required | Lower upfront cost, higher ink consumption |

| Health & Safety | Minimal harmful emissions, requires UV protection | Strong fumes, requires proper ventilation |

Introduction to UV Curable Ink and Solvent Based Ink

UV curable ink consists of pigments dispersed in a liquid resin that hardens when exposed to ultraviolet light, offering faster drying times and enhanced durability compared to solvent-based ink, which relies on chemical solvents to evaporate and leave the pigment on the substrate. UV curable inks provide superior adhesion, environmental benefits due to low volatile organic compounds (VOCs), and are ideal for printing on a variety of non-porous surfaces. Solvent-based inks, known for their strong color vibrancy and flexibility, are widely used in outdoor applications but pose higher environmental and health risks due to the release of VOCs during the drying process.

Composition and Chemical Properties

UV curable ink consists of acrylate monomers and oligomers that polymerize instantly under UV light, offering excellent adhesion and vibrant color stability without volatile organic compounds (VOCs). Solvent-based ink contains organic solvents that dissolve pigments and facilitate drying through evaporation, which can emit VOCs and require proper ventilation during use. Understanding these chemical properties helps you select the right ink for durability, environmental impact, and substrate compatibility.

Printing Process and Curing Mechanisms

UV curable ink undergoes rapid polymerization when exposed to ultraviolet light, which instantly cures the ink by transforming liquid monomers into a solid film, enabling faster printing speeds and immediate handling. In contrast, solvent-based ink relies on the evaporation of solvents during the drying process, which takes longer and produces volatile organic compounds that require ventilation. Your choice between these inks impacts printing efficiency, environmental safety, and substrate compatibility due to their distinct curing mechanisms and processing times.

Substrate Compatibility

UV curable ink offers excellent substrate compatibility, adhering well to a wide range of non-porous materials such as plastics, glass, metals, and coated papers, making it ideal for applications requiring quick curing and durable prints. Solvent-based ink excels on porous substrates like vinyl, banners, and uncoated papers, providing deep penetration and vibrant colors, but it may cause material degradation or require ventilation due to strong odor and VOC emissions. Choosing between UV curable and solvent-based ink depends heavily on the substrate type and desired print durability, with UV inks favored for smooth, rigid surfaces and solvent inks preferred for flexible, porous media.

Environmental Impact and Safety

UV curable ink significantly reduces environmental impact by emitting fewer volatile organic compounds (VOCs) compared to solvent-based ink, which releases higher levels of harmful VOCs during drying. UV inks cure instantly under ultraviolet light, minimizing hazardous air pollutants and reducing the risk of toxic exposure to your workspace. Choosing UV curable ink enhances safety for operators while supporting eco-friendly printing practices.

Print Quality and Durability Comparison

UV curable ink delivers superior print quality with vibrant colors, sharp details, and excellent adhesion on various substrates due to its instant curing process. Solvent-based ink offers strong durability and resistance to outdoor elements but may exhibit longer drying times and potential odor issues. Your choice depends on the required print longevity and the specific application environment.

Drying Time and Production Efficiency

UV curable inks dry almost instantly when exposed to ultraviolet light, significantly reducing drying time compared to solvent-based inks that rely on evaporation, which can take minutes to hours. This rapid curing process with UV inks enhances production efficiency by allowing immediate handling and faster turnaround times without waiting for solvent evaporation. Your printing workflow benefits from minimized downtime and higher throughput when using UV curable inks over solvent-based alternatives.

Cost Analysis and Economic Considerations

UV curable ink typically involves higher upfront costs due to specialized curing equipment, but offers lower long-term expenses with faster drying times and reduced material waste, enhancing overall economic efficiency. Solvent-based ink generally has lower initial investment but incurs ongoing costs linked to ventilation, storage, and environmental regulations, impacting total cost of ownership. Your choice should weigh initial capital outlay against operational savings and compliance expenses to optimize cost-effectiveness.

Common Applications in the Industry

UV curable ink is widely used in packaging, labels, and promotional products due to its fast curing time and environmental benefits. Solvent-based ink is preferred for outdoor signage, vehicle wraps, and industrial printing because of its durability and resistance to harsh weather conditions. Both inks serve critical roles in high-demand industries, with UV curable ink excelling in eco-friendly, high-quality prints and solvent-based ink dominating in robust, long-lasting applications.

Choosing the Right Ink for Your Needs

UV curable ink offers rapid drying times and superior adhesion on a variety of substrates, making it ideal for high-speed production and eco-friendly applications. Solvent-based ink provides deep color saturation and durability, excelling in outdoor signage and heavy-duty industrial printing. Selecting the right ink depends on factors such as substrate compatibility, environmental impact, print quality, and production speed requirements.

UV curable ink vs Solvent based ink Infographic

electrown.com

electrown.com