LCP (Largest Contentful Paint) measures the loading performance of the largest visible element on your page, while PET (Perceptual Experience Time) focuses on the user's perception of when the page is ready for interaction. Understanding the differences between LCP and PET can help you optimize your website's user experience--read on to discover how to improve both metrics effectively.

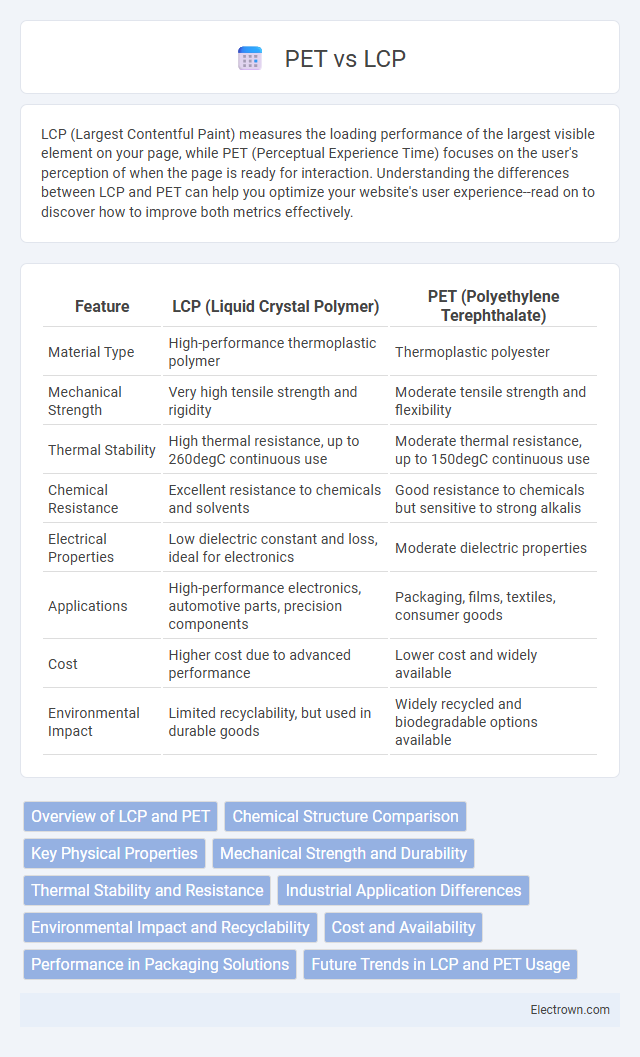

Table of Comparison

| Feature | LCP (Liquid Crystal Polymer) | PET (Polyethylene Terephthalate) |

|---|---|---|

| Material Type | High-performance thermoplastic polymer | Thermoplastic polyester |

| Mechanical Strength | Very high tensile strength and rigidity | Moderate tensile strength and flexibility |

| Thermal Stability | High thermal resistance, up to 260degC continuous use | Moderate thermal resistance, up to 150degC continuous use |

| Chemical Resistance | Excellent resistance to chemicals and solvents | Good resistance to chemicals but sensitive to strong alkalis |

| Electrical Properties | Low dielectric constant and loss, ideal for electronics | Moderate dielectric properties |

| Applications | High-performance electronics, automotive parts, precision components | Packaging, films, textiles, consumer goods |

| Cost | Higher cost due to advanced performance | Lower cost and widely available |

| Environmental Impact | Limited recyclability, but used in durable goods | Widely recycled and biodegradable options available |

Overview of LCP and PET

Liquid Crystal Polymer (LCP) is a high-performance engineering thermoplastic known for its exceptional mechanical strength, thermal stability, and chemical resistance, making it ideal for applications in electronics, automotive, and aerospace industries. Polyethylene Terephthalate (PET) is a widely used polyester polymer recognized for its versatility, clarity, and excellent barrier properties, commonly employed in packaging, fibers, and beverage containers. Comparing LCP and PET highlights LCP's advanced durability and thermal resistance against PET's cost-effectiveness and ease of processing.

Chemical Structure Comparison

LCP (Liquid Crystal Polymer) and PET (Polyethylene Terephthalate) differ significantly in chemical structure, impacting their performance characteristics. LCP features rigid aromatic polymer chains with mesogenic groups that provide extraordinary thermal stability and mechanical strength. PET, a semi-crystalline polyester made from terephthalic acid and ethylene glycol, offers good flexibility and chemical resistance but lacks the high-temperature resilience of LCP.

Key Physical Properties

LCP (Liquid Crystal Polymer) exhibits exceptional tensile strength, high melting point around 280degC, and excellent chemical resistance, making it ideal for high-performance applications. PET (Polyethylene Terephthalate) offers good mechanical strength, a melting point near 250degC, and superior clarity with moderate chemical resistance. Your choice between LCP and PET should consider the specific physical properties required, such as thermal stability, flexibility, and strength for your application.

Mechanical Strength and Durability

LCP (Liquid Crystal Polymer) exhibits superior mechanical strength and exceptional durability compared to PET (Polyethylene Terephthalate), making it ideal for high-performance applications requiring resistance to wear and stress. LCP's molecular structure provides high tensile strength and excellent thermal stability, ensuring longevity even under harsh conditions. Your choice of LCP over PET can significantly enhance product resilience and lifespan in demanding environments.

Thermal Stability and Resistance

LCP (Liquid Crystal Polymer) exhibits superior thermal stability compared to PET (Polyethylene Terephthalate), withstanding continuous use at temperatures up to 280degC versus PET's limit around 150degC. The inherent molecular structure of LCP provides enhanced resistance to thermal deformation and chemical degradation, making it ideal for high-temperature applications. Your choice between these materials will depend on the necessity of high thermal resistance and durability in demanding environments.

Industrial Application Differences

LCP (Liquid Crystal Polymer) excels in high-temperature resistance and mechanical strength, making it ideal for advanced electronics, automotive components, and aerospace applications where durability under extreme conditions is critical. PET (Polyethylene Terephthalate) offers excellent chemical resistance and clarity, commonly utilized in packaging, fibers, and electrical insulation due to its cost-effectiveness and flexibility. Your choice between LCP and PET depends on the specific industrial requirements for thermal stability, mechanical performance, and environmental exposure.

Environmental Impact and Recyclability

LCP (Liquid Crystal Polymer) offers superior chemical resistance and mechanical strength but poses challenges in recycling due to limited recycling streams and higher processing costs. PET (Polyethylene Terephthalate) is widely recycled with established infrastructure, significantly reducing environmental impact through effective reuse and lower carbon footprint. In terms of lifecycle assessment, PET demonstrates greater sustainability potential, while LCP requires advancements in recycling technology to mitigate its ecological effects.

Cost and Availability

LCP (Liquid Crystal Polymer) typically incurs higher costs compared to PET (Polyethylene Terephthalate) due to its advanced mechanical properties and specialized manufacturing processes. PET is widely available and cost-effective, benefiting from large-scale production and extensive supply chains in packaging and textile industries. While LCP offers superior thermal resistance and chemical stability, PET's affordability and easy accessibility make it the preferred choice for mass-market applications.

Performance in Packaging Solutions

LCP (Liquid Crystal Polymer) offers superior barrier properties and chemical resistance, making it ideal for high-performance packaging solutions requiring durability and protection. PET (Polyethylene Terephthalate) provides excellent clarity, toughness, and recyclability, commonly used for food and beverage containers to ensure freshness and consumer safety. Your choice between LCP and PET should consider factors like mechanical strength, moisture barrier efficiency, and environmental impact to optimize packaging performance.

Future Trends in LCP and PET Usage

Future trends in LCP (Liquid Crystal Polymer) and PET (Polyethylene Terephthalate) usage highlight increasing adoption of LCP in high-performance electronics and medical devices due to its superior heat resistance and mechanical strength. PET continues to dominate packaging and textile industries because of its recyclability and cost-effectiveness, with innovations geared toward enhancing biodegradability and sustainability. Your choice between LCP and PET should consider the evolving market demands and material advancements aligning with environmental regulations and application-specific requirements.

LCP vs PET Infographic

electrown.com

electrown.com