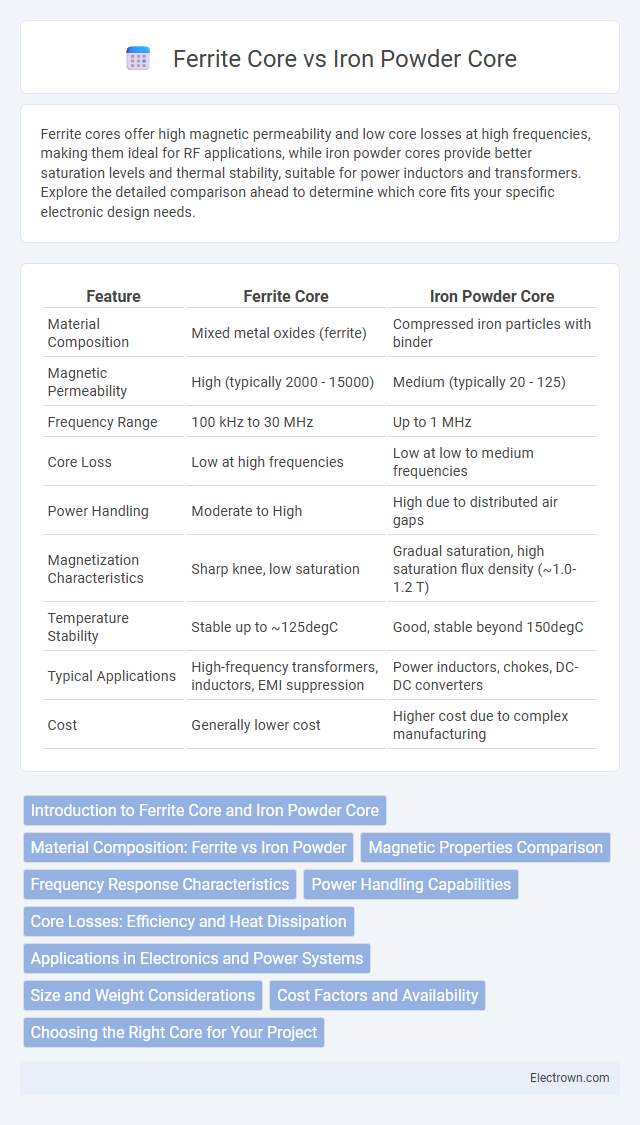

Ferrite cores offer high magnetic permeability and low core losses at high frequencies, making them ideal for RF applications, while iron powder cores provide better saturation levels and thermal stability, suitable for power inductors and transformers. Explore the detailed comparison ahead to determine which core fits your specific electronic design needs.

Table of Comparison

| Feature | Ferrite Core | Iron Powder Core |

|---|---|---|

| Material Composition | Mixed metal oxides (ferrite) | Compressed iron particles with binder |

| Magnetic Permeability | High (typically 2000 - 15000) | Medium (typically 20 - 125) |

| Frequency Range | 100 kHz to 30 MHz | Up to 1 MHz |

| Core Loss | Low at high frequencies | Low at low to medium frequencies |

| Power Handling | Moderate to High | High due to distributed air gaps |

| Magnetization Characteristics | Sharp knee, low saturation | Gradual saturation, high saturation flux density (~1.0-1.2 T) |

| Temperature Stability | Stable up to ~125degC | Good, stable beyond 150degC |

| Typical Applications | High-frequency transformers, inductors, EMI suppression | Power inductors, chokes, DC-DC converters |

| Cost | Generally lower cost | Higher cost due to complex manufacturing |

Introduction to Ferrite Core and Iron Powder Core

Ferrite cores are made from ceramic compounds consisting of iron oxide mixed with metallic elements, offering high magnetic permeability and low electrical conductivity, which reduces eddy current losses at high frequencies. Iron powder cores consist of compressed iron particles combined with a binder, providing distributed air gaps that improve saturation characteristics and minimize core losses in medium-frequency applications. Understanding these core types helps optimize your magnetic components for specific electrical and magnetic performance needs.

Material Composition: Ferrite vs Iron Powder

Ferrite cores are composed primarily of ceramic compounds made from iron oxide combined with metallic elements such as manganese, zinc, or nickel, resulting in high magnetic permeability and low electrical conductivity. Iron powder cores consist of finely ground iron particles mixed with a binder, offering moderate permeability with improved mechanical strength and lower core losses at high frequencies. The distinct material compositions of ferrite and iron powder cores directly influence their magnetic performance, frequency response, and application suitability in electronic inductors and transformers.

Magnetic Properties Comparison

Ferrite cores exhibit high magnetic permeability and low core loss at high frequencies, making them ideal for RF applications and transformers operating above 100 kHz. Iron powder cores offer moderate permeability with distributed air gaps, resulting in lower permeability but better saturation characteristics and reduced eddy current losses in power inductors. Your choice between ferrite and iron powder cores should consider frequency range, saturation flux density, and core loss to optimize magnetic performance in your design.

Frequency Response Characteristics

Ferrite cores exhibit excellent performance at high frequencies, typically ranging from 50 kHz up to several MHz, due to their low eddy current losses and high magnetic permeability. Iron powder cores, in contrast, are better suited for lower frequency applications, usually below 500 kHz, as they have higher core losses at elevated frequencies caused by eddy currents. Your choice between ferrite and iron powder cores will depend on the frequency range of your application, with ferrite cores offering superior frequency response for high-frequency designs.

Power Handling Capabilities

Ferrite cores offer higher power handling capabilities due to their low core losses and high magnetic permeability, making them ideal for high-frequency applications. Iron powder cores, while having lower permeability, excel in handling higher DC bias currents without saturation, which benefits circuits requiring stable inductance under heavy load. Your choice depends on whether the application prioritizes high-frequency efficiency or robust DC current management.

Core Losses: Efficiency and Heat Dissipation

Ferrite cores exhibit lower core losses at high frequencies, resulting in improved efficiency and reduced heat dissipation compared to iron powder cores. Iron powder cores, while offering better mechanical strength and saturation characteristics, tend to generate higher core losses that increase heat buildup under high-frequency operation. Selecting ferrite cores is optimal for applications requiring minimal energy loss and effective thermal management in switching power supplies and RF transformers.

Applications in Electronics and Power Systems

Ferrite cores are widely used in high-frequency transformers and inductors due to their low eddy current losses and excellent magnetic properties, making them ideal for applications in switching power supplies, RF circuits, and EMI suppression. Iron powder cores provide higher saturation flux density and better performance in DC bias conditions, which suits them well for power inductors in DC-DC converters and audio frequency applications. Choosing the right core material for your electronics or power system depends on factors like operating frequency, thermal stability, and magnetic saturation requirements.

Size and Weight Considerations

Ferrite cores typically offer a smaller size and lighter weight compared to iron powder cores, making them ideal for compact electronic devices where space and weight are critical. Iron powder cores, due to their higher mass and larger volume, are better suited for applications requiring higher power handling and thermal stability. You should consider ferrite cores for lightweight designs but opt for iron powder cores when durability and heat dissipation are priorities.

Cost Factors and Availability

Ferrite cores generally offer a lower cost and higher availability compared to iron powder cores due to their widespread use in high-frequency applications and mass production efficiency. Iron powder cores tend to be more expensive and less readily available since they are specialized for applications requiring higher saturation flux density and better losses at medium frequencies. Your choice should consider budget constraints and supply chain accessibility to ensure optimal performance and cost-effectiveness.

Choosing the Right Core for Your Project

Ferrite cores offer high magnetic permeability and low eddy current losses, making them ideal for high-frequency applications such as transformers and inductors in RF circuits. Iron powder cores provide stable permeability and higher saturation levels, which suit power inductors and chokes needing greater energy storage and thermal stability. Selecting between ferrite and iron powder cores depends on your project's frequency range, power handling requirements, and thermal conditions for optimal performance.

ferrite core vs iron powder core Infographic

electrown.com

electrown.com