Flange mount motors offer compact installation with precise alignment, ideal for applications requiring direct coupling, while foot mount motors provide versatile support and easier maintenance for machinery with standard base frames. Explore the article to determine which motor mounting style best suits Your specific needs and operational demands.

Table of Comparison

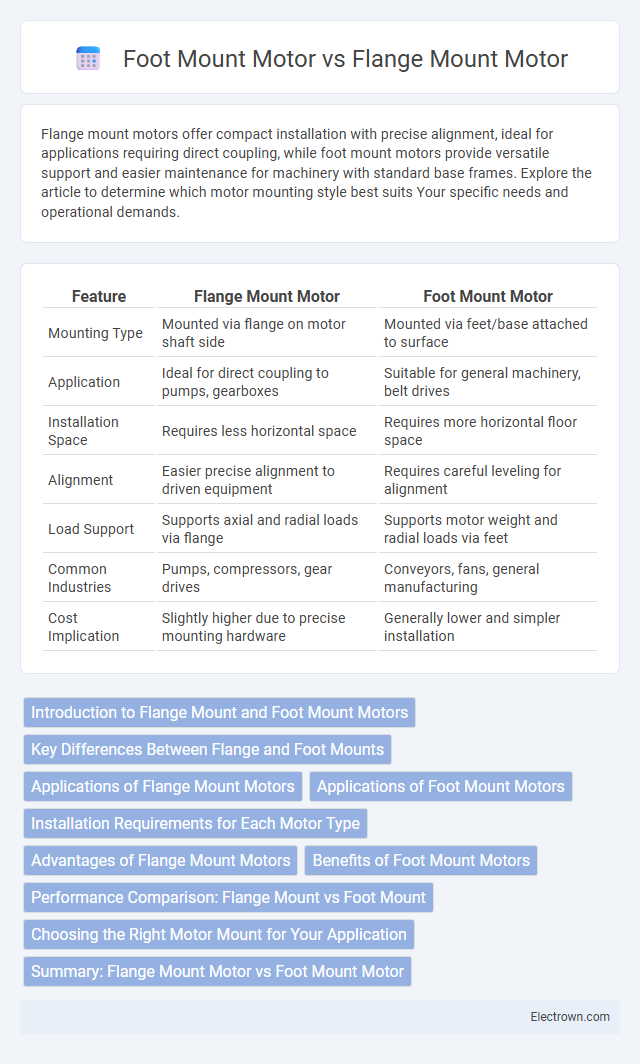

| Feature | Flange Mount Motor | Foot Mount Motor |

|---|---|---|

| Mounting Type | Mounted via flange on motor shaft side | Mounted via feet/base attached to surface |

| Application | Ideal for direct coupling to pumps, gearboxes | Suitable for general machinery, belt drives |

| Installation Space | Requires less horizontal space | Requires more horizontal floor space |

| Alignment | Easier precise alignment to driven equipment | Requires careful leveling for alignment |

| Load Support | Supports axial and radial loads via flange | Supports motor weight and radial loads via feet |

| Common Industries | Pumps, compressors, gear drives | Conveyors, fans, general manufacturing |

| Cost Implication | Slightly higher due to precise mounting hardware | Generally lower and simpler installation |

Introduction to Flange Mount and Foot Mount Motors

Flange mount motors feature a protruding, flat mounting surface with pre-drilled holes, allowing secure attachment directly to machinery or equipment faces, which optimizes space and alignment in compact setups. Foot mount motors include sturdy base plates with bolt holes, enabling stable installation on flat surfaces where vibration resistance and easy access for maintenance are priorities. Selecting between flange mount and foot mount motors depends on your specific application needs, spatial constraints, and installation preferences.

Key Differences Between Flange and Foot Mounts

Flange mount motors are designed with a circular plate allowing direct attachment to machinery, providing precise alignment and saving space in compact applications. Foot mount motors feature a base with mounting feet, offering flexibility in installation and better stability on flat surfaces. The choice between flange and foot mounts hinges on equipment design, space constraints, and required motor alignment.

Applications of Flange Mount Motors

Flange mount motors are commonly used in applications requiring precise alignment and compact installation, such as conveyor systems, pumps, and machine tools. Their design allows for direct connection to the driven equipment, minimizing misalignment and simplifying maintenance. If your setup demands efficient space utilization and secure mounting, flange mount motors provide a reliable solution tailored to industrial automation and manufacturing processes.

Applications of Foot Mount Motors

Foot mount motors are widely used in industrial applications requiring stable and secure motor positioning, such as conveyor systems, pumps, and compressors. Their base-mounted design allows easy installation and alignment on flat surfaces, making them ideal for heavy-duty applications with significant vibration and load. These motors provide enhanced durability and maintenance accessibility in manufacturing plants, material handling, and HVAC systems.

Installation Requirements for Each Motor Type

Flange mount motors require precise alignment with the equipment's flange, demanding accurate bolt hole matching and tight tolerances during installation to ensure secure attachment and optimal performance. Foot mount motors need a stable and flat base surface for proper mounting, with careful attention to bolt placement and vibration isolation to prevent misalignment or operational issues. Your choice depends on the machinery design and available space, as flange mount motors are ideal for compact setups, while foot mount motors suit applications needing stable foundation support.

Advantages of Flange Mount Motors

Flange mount motors offer superior alignment precision and space-saving installation compared to foot mount motors, making them ideal for applications with limited floor space. Their direct coupling capability reduces shaft misalignment and vibration, which enhances operational efficiency and extends motor lifespan. Additionally, flange mount motors provide better support for axial and radial loads, improving overall system stability and performance.

Benefits of Foot Mount Motors

Foot mount motors offer superior stability and easier alignment in heavy-duty applications, reducing vibration and mechanical stress on your equipment. Their design allows for simpler installation and maintenance in machinery with horizontal shafts or limited space. These benefits make foot mount motors ideal for industrial settings requiring robust, reliable performance.

Performance Comparison: Flange Mount vs Foot Mount

Flange mount motors offer higher precision alignment and reduced shaft deflection, making them ideal for applications requiring accurate torque transmission and compact installation. Foot mount motors provide greater stability and ease of maintenance due to their robust base, supporting heavier loads and vibrations in industrial settings. Performance differences between the two primarily depend on the specific requirements of torque, load capacity, and spatial constraints in the intended machinery.

Choosing the Right Motor Mount for Your Application

Selecting the right motor mount depends on the application's space constraints and load requirements. Flange mount motors offer compact installation with direct coupling to equipment, ideal for precise alignment and minimal footprint. Foot mount motors provide stability and support in larger setups, ensuring your motor remains securely positioned under heavy loads.

Summary: Flange Mount Motor vs Foot Mount Motor

Flange mount motors offer compact installation by attaching directly to equipment via a flange, making them ideal for applications requiring precise alignment and space efficiency. Foot mount motors provide robust support through a base with feet, suited for heavy-duty operations requiring stable, vibration-resistant setups. Your choice depends on spatial constraints and mounting surface, with flange mounts optimizing machinery integration and foot mounts ensuring structural stability.

Flange Mount Motor vs Foot Mount Motor Infographic

electrown.com

electrown.com