Forward polarity protection ensures your device operates safely by allowing current to flow only when the power supply is connected correctly, preventing damage from reversed connections. Understanding the differences between forward and reverse polarity protection can help you safeguard your electronics effectively--explore the rest of the article to learn more.

Table of Comparison

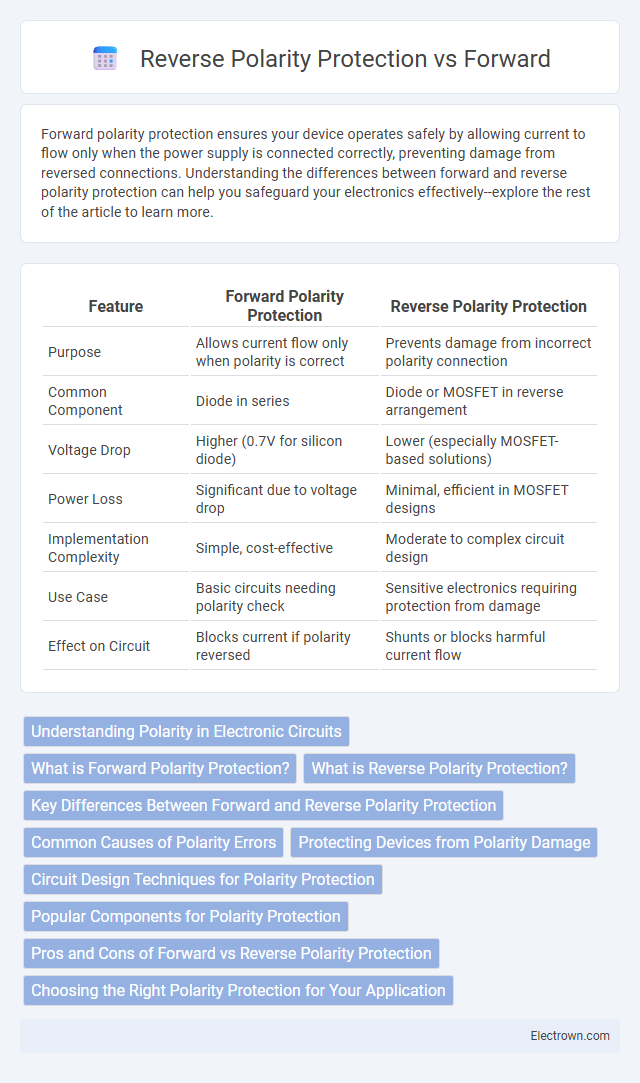

| Feature | Forward Polarity Protection | Reverse Polarity Protection |

|---|---|---|

| Purpose | Allows current flow only when polarity is correct | Prevents damage from incorrect polarity connection |

| Common Component | Diode in series | Diode or MOSFET in reverse arrangement |

| Voltage Drop | Higher (0.7V for silicon diode) | Lower (especially MOSFET-based solutions) |

| Power Loss | Significant due to voltage drop | Minimal, efficient in MOSFET designs |

| Implementation Complexity | Simple, cost-effective | Moderate to complex circuit design |

| Use Case | Basic circuits needing polarity check | Sensitive electronics requiring protection from damage |

| Effect on Circuit | Blocks current if polarity reversed | Shunts or blocks harmful current flow |

Understanding Polarity in Electronic Circuits

Polarity in electronic circuits refers to the correct direction of current flow, essential for devices like diodes and capacitors to operate properly. Forward polarity protection allows current to flow in the intended direction, preventing damage from incorrect voltage application. Reverse polarity protection safeguards your circuit by blocking or diverting current when connections are reversed, ensuring component safety and system reliability.

What is Forward Polarity Protection?

Forward polarity protection ensures that electrical devices function correctly when the power supply's positive and negative terminals are connected as intended, preventing damage caused by incorrect polarity. This protection method typically uses components such as diodes or specialized circuits to allow current flow only in the correct direction. Understanding forward polarity protection helps you safeguard your electronics from common wiring errors and improves device reliability.

What is Reverse Polarity Protection?

Reverse Polarity Protection is a circuit design feature that prevents damage to electronic devices caused by incorrect connection of power supply terminals. It detects if the positive and negative voltage inputs are swapped and either blocks current flow or safely redirects it, ensuring device functionality and safety. Common methods include diode-based protection and MOSFET-based circuits, optimized for minimal voltage drop and efficient power handling.

Key Differences Between Forward and Reverse Polarity Protection

Forward polarity protection allows current to flow only when the voltage is applied correctly, preventing damage to circuits by blocking incorrect polarity connections from the start. Reverse polarity protection actively prevents harm by blocking or redirecting current flow when voltage is applied in reverse, often using diodes or MOSFETs for rapid response. Understanding these key differences helps ensure Your electronics remain safe from damage caused by incorrect power supply connections.

Common Causes of Polarity Errors

Common causes of polarity errors include incorrect wiring during device installation, damaged cables with reversed conductor positions, and human error when connecting power sources to electronic components. Mislabeling of terminals and inconsistent industry standards for positive and negative connections also contribute to polarity reversal incidents. These errors can result in circuit malfunction, device damage, or hazardous electrical faults if not detected and protected against.

Protecting Devices from Polarity Damage

Forward polarity protection ensures your device receives the correct voltage by allowing current flow only when the polarity is correct, preventing damage from accidental reverse connections. Reverse polarity protection uses components like diodes or MOSFETs to block or redirect current when the polarity is reversed, safeguarding sensitive electronics from potential harm. Choosing the right protection method depends on your device's voltage sensitivity and power efficiency requirements.

Circuit Design Techniques for Polarity Protection

Circuit design techniques for polarity protection include using diodes and MOSFETs to prevent damage from incorrect battery or power supply connections. Forward polarity protection typically employs a series diode to allow normal current flow while blocking reverse polarity, but it introduces voltage drop and power loss. Reverse polarity protection often utilizes P-channel MOSFETs in a low-side switch configuration or N-channel MOSFETs with a high-side driver, offering low resistance and minimal voltage drop for efficient protection.

Popular Components for Polarity Protection

Popular components for polarity protection include diodes, MOSFETs, and P-channel transistors, each offering distinct advantages for forward and reverse polarity scenarios. Schottky diodes are favored for their low forward voltage drop in forward polarity protection, while MOSFETs provide efficient reverse polarity protection with minimal power loss due to their low on-resistance. P-channel MOSFETs simplify circuit design by automatically blocking reverse currents, ensuring device safety in various electronic applications.

Pros and Cons of Forward vs Reverse Polarity Protection

Forward polarity protection offers low voltage drop and high efficiency, making it ideal for power-sensitive applications, but it provides limited protection against accidental reverse connections. Reverse polarity protection effectively safeguards circuits by blocking current flow during incorrect polarity, often using components like diodes or MOSFETs, but it can introduce higher voltage drops and power loss. Choosing between the two depends on balancing efficiency requirements with the level of protection needed against wiring errors.

Choosing the Right Polarity Protection for Your Application

Selecting the right polarity protection depends on the specific requirements of your circuit, including voltage, current, and power efficiency. Forward polarity protection uses diodes for simplicity but incurs voltage drop and power loss, while reverse polarity protection often employs MOSFET-based solutions to reduce energy dissipation and maintain circuit integrity. Evaluating factors such as response speed, component size, and thermal performance ensures optimal protection tailored to your application's demands.

Forward vs Reverse Polarity Protection Infographic

electrown.com

electrown.com