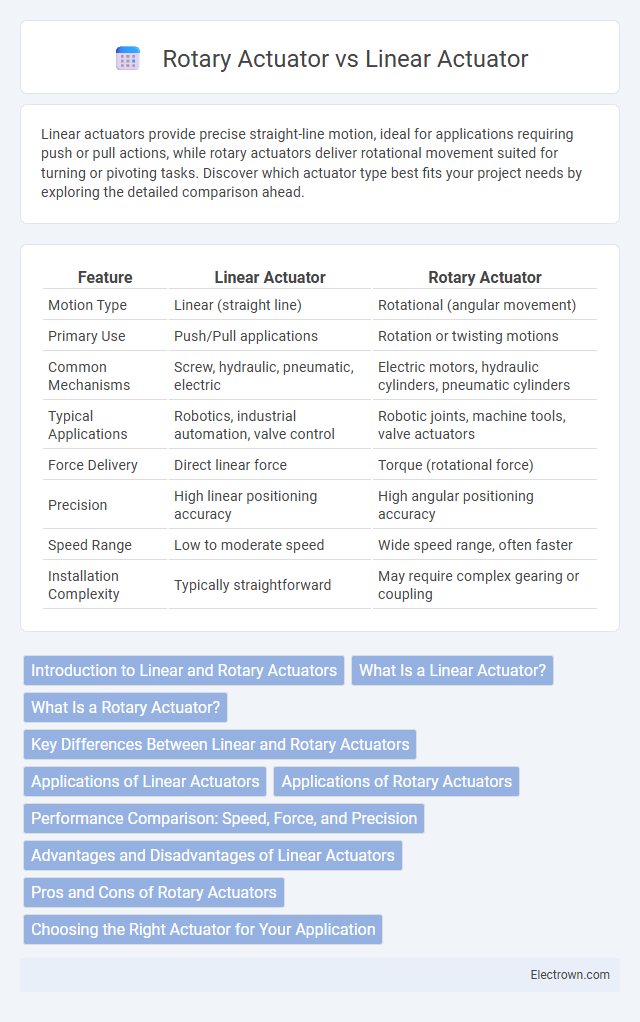

Linear actuators provide precise straight-line motion, ideal for applications requiring push or pull actions, while rotary actuators deliver rotational movement suited for turning or pivoting tasks. Discover which actuator type best fits your project needs by exploring the detailed comparison ahead.

Table of Comparison

| Feature | Linear Actuator | Rotary Actuator |

|---|---|---|

| Motion Type | Linear (straight line) | Rotational (angular movement) |

| Primary Use | Push/Pull applications | Rotation or twisting motions |

| Common Mechanisms | Screw, hydraulic, pneumatic, electric | Electric motors, hydraulic cylinders, pneumatic cylinders |

| Typical Applications | Robotics, industrial automation, valve control | Robotic joints, machine tools, valve actuators |

| Force Delivery | Direct linear force | Torque (rotational force) |

| Precision | High linear positioning accuracy | High angular positioning accuracy |

| Speed Range | Low to moderate speed | Wide speed range, often faster |

| Installation Complexity | Typically straightforward | May require complex gearing or coupling |

Introduction to Linear and Rotary Actuators

Linear actuators convert energy into straight-line motion, commonly used in applications requiring precise positioning, such as robotics and industrial machinery. Rotary actuators generate rotational motion, ideal for tasks involving torque and angular displacement, often found in valve control and automated systems. Understanding your specific motion needs helps determine whether a linear or rotary actuator is best suited for your application.

What Is a Linear Actuator?

A linear actuator is a mechanical device that creates motion in a straight line, essential for applications requiring precise linear displacement and force. It operates by converting energy, typically electrical, hydraulic, or pneumatic, into linear motion, enabling automation in various industries such as robotics, aerospace, and manufacturing. Linear actuators are valued for their accuracy, reliability, and ability to handle heavy loads with smooth, controlled movements.

What Is a Rotary Actuator?

A rotary actuator is a mechanical device that converts energy into rotational motion, enabling precise angular displacement in various applications such as robotics, automation, and industrial machinery. Unlike linear actuators that provide straight-line movement, rotary actuators generate torque to rotate components around a fixed axis. Common types include electric, hydraulic, and pneumatic rotary actuators, each optimized for specific torque, speed, and control requirements.

Key Differences Between Linear and Rotary Actuators

Linear actuators produce motion in a straight line, ideal for applications requiring precise linear displacement, while rotary actuators generate rotational movement, suited for tasks involving continuous or limited rotation. Key differences include their motion type, design complexity, and typical use cases: linear actuators often utilize screw drives or pneumatic cylinders, whereas rotary actuators may employ gears or motors to achieve angular movement. Understanding these distinctions helps you select the appropriate actuator based on your project's motion requirements and spatial constraints.

Applications of Linear Actuators

Linear actuators are widely used in industrial automation, robotics, and medical equipment for precise control of motion in a straight line. Your projects benefit from their ability to convert energy into linear displacement, making them ideal for applications such as adjustable hospital beds, conveyor systems, and solar panel positioning. Compared to rotary actuators, linear actuators offer direct, linear movement that enhances efficiency and accuracy in tasks requiring push-pull actions.

Applications of Rotary Actuators

Rotary actuators are widely used in industrial automation for precise control of angular motion, including valve operation, robotic arm movement, and packaging machinery. Their ability to deliver controlled torque and rotate within a specified angle range makes them essential in aerospace systems, automotive steering mechanisms, and conveyor belt turntables. Common applications include indexing tables, machine tools, and automated assembly lines where accurate, repeatable rotation is critical.

Performance Comparison: Speed, Force, and Precision

Linear actuators typically deliver higher force and precise linear motion suited for applications requiring direct push or pull actions, while rotary actuators excel in speed and continuous rotational movement with smoother torque control. Speed in rotary actuators often surpasses that of linear actuators due to their design, enabling rapid angular displacement, whereas linear actuators prioritize controlled, steady movement for accuracy. Precision in linear actuators relies on lead screw or ball screw mechanisms allowing fine positional adjustments, contrasting with rotary actuators that depend on encoders and gearing systems for angular resolution.

Advantages and Disadvantages of Linear Actuators

Linear actuators offer precise control and direct motion along a straight path, making them ideal for applications requiring accurate positioning and force control. Their simplicity in design and ease of integration provide reliable and low-maintenance operation, but limitations include slower speeds and shorter stroke lengths compared to rotary actuators. Linear actuators are less suited for continuous rotational motion and may require more space for installation due to their extended linear travel.

Pros and Cons of Rotary Actuators

Rotary actuators provide precise angular movement and are ideal for applications requiring rotational motion with high torque and speed control, such as robotics and valve operation. Their compact design and ability to deliver continuous rotation make them suitable for tight spaces and repetitive tasks, but they may struggle with linear force applications and can be less efficient in converting rotational motion to linear displacement. Maintenance complexity and cost can be higher due to gear systems and the need for accurate calibration compared to simpler linear actuators.

Choosing the Right Actuator for Your Application

Selecting the right actuator depends on the specific movement requirements and load types in your application. Linear actuators provide precise straight-line motion, ideal for lifting, pushing, or pulling tasks, while rotary actuators offer rotational movement suited for turning or pivoting operations. Consider factors such as stroke length, torque, speed, and environmental conditions to optimize performance and efficiency.

Linear Actuator vs Rotary Actuator Infographic

electrown.com

electrown.com