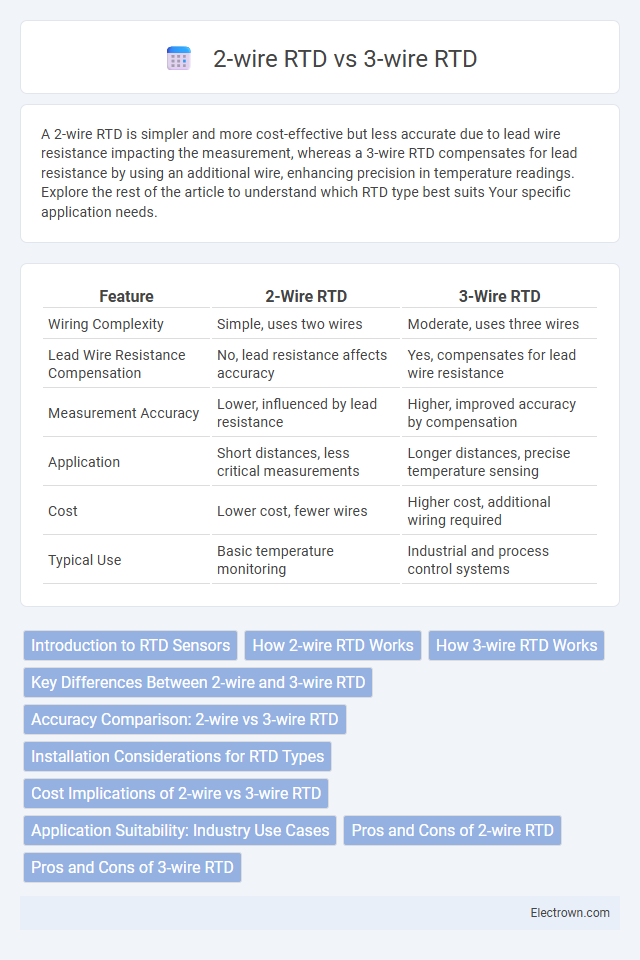

A 2-wire RTD is simpler and more cost-effective but less accurate due to lead wire resistance impacting the measurement, whereas a 3-wire RTD compensates for lead resistance by using an additional wire, enhancing precision in temperature readings. Explore the rest of the article to understand which RTD type best suits Your specific application needs.

Table of Comparison

| Feature | 2-Wire RTD | 3-Wire RTD |

|---|---|---|

| Wiring Complexity | Simple, uses two wires | Moderate, uses three wires |

| Lead Wire Resistance Compensation | No, lead resistance affects accuracy | Yes, compensates for lead wire resistance |

| Measurement Accuracy | Lower, influenced by lead resistance | Higher, improved accuracy by compensation |

| Application | Short distances, less critical measurements | Longer distances, precise temperature sensing |

| Cost | Lower cost, fewer wires | Higher cost, additional wiring required |

| Typical Use | Basic temperature monitoring | Industrial and process control systems |

Introduction to RTD Sensors

RTD sensors measure temperature by correlating the resistance of a metal with temperature changes, with 2-wire RTDs having a simplified design where lead wire resistance affects accuracy. 3-wire RTDs enhance measurement precision by compensating for lead resistance, making them ideal for industrial applications requiring higher accuracy. The choice between 2-wire and 3-wire RTDs depends on the required accuracy and environmental factors influencing resistance measurement.

How 2-wire RTD Works

2-wire RTDs measure temperature by passing current through two wires connected to the sensor and measuring the voltage drop, which correlates with resistance changes caused by temperature variations. However, this setup includes resistance from the lead wires, leading to measurement inaccuracies, especially in long wire runs. The simple configuration makes 2-wire RTDs cost-effective but less precise compared to 3-wire RTDs that compensate for lead wire resistance.

How 3-wire RTD Works

A 3-wire RTD compensates for lead wire resistance by using three separate wires, allowing the measurement device to subtract the resistance of one lead from the total resistance, resulting in accurate temperature readings. The two leads carry the current through the RTD sensor, while the third lead serves as a reference to measure and eliminate the resistance of the lead wires. This configuration significantly improves measurement accuracy compared to the standard 2-wire RTD, which cannot account for lead wire resistance.

Key Differences Between 2-wire and 3-wire RTD

2-wire RTDs have two lead wires and are prone to measurement errors caused by lead wire resistance, making them less accurate for long-distance measurements. In contrast, 3-wire RTDs include a third lead wire to compensate for lead resistance, improving accuracy by allowing the measurement system to subtract the lead wire resistance from the total resistance. The 3-wire configuration is preferred in industrial applications where precise temperature readings are essential, especially in environments with longer cable runs.

Accuracy Comparison: 2-wire vs 3-wire RTD

2-wire RTDs are less accurate due to the resistance of the lead wires affecting the measurement, introducing potential errors especially over long distances. In contrast, 3-wire RTDs improve accuracy by compensating for lead wire resistance, making them more reliable for precise temperature monitoring in industrial applications. Your choice should consider the trade-off between simplicity and the need for accurate temperature readings, where 3-wire RTDs typically offer better performance.

Installation Considerations for RTD Types

2-wire RTDs offer simpler installation with fewer wiring requirements but are more susceptible to lead wire resistance errors, which can affect measurement accuracy. 3-wire RTDs improve accuracy by compensating for lead wire resistance, making them ideal for industrial environments where longer cable runs are common. When selecting your RTD type, consider the balance between installation complexity and the precision needed for your temperature measurements.

Cost Implications of 2-wire vs 3-wire RTD

2-wire RTDs are generally more cost-effective due to fewer components and simpler installation, reducing material and labor expenses. However, they are less accurate because lead wire resistance affects the measurement, which might result in additional calibration costs. 3-wire RTDs offer improved accuracy by compensating for lead resistance, potentially lowering long-term maintenance and calibration expenses despite the higher initial cost.

Application Suitability: Industry Use Cases

2-wire RTDs are commonly used in low-cost, non-critical industrial applications where lead wire resistance has minimal impact, such as HVAC systems and simple temperature monitoring. 3-wire RTDs are preferred in more precise industrial environments like chemical processing and power plants, where compensating for lead wire resistance is essential for accurate temperature measurement. Your choice depends on the required accuracy and the complexity of the installation environment.

Pros and Cons of 2-wire RTD

2-wire RTDs offer simplicity and cost-effectiveness due to fewer wiring requirements, making them suitable for short-distance temperature measurements where accuracy demands are lower. However, they are less accurate because wire resistance adds to the measurement, causing errors that increase with lead length. This limitation makes 2-wire RTDs less ideal for industrial applications requiring precise temperature control compared to 3-wire RTDs, which compensate for lead resistance and improve accuracy.

Pros and Cons of 3-wire RTD

A 3-wire RTD offers improved accuracy by compensating for lead wire resistance, making it more reliable for precise temperature measurements compared to a 2-wire RTD. Its main advantage is reduced measurement error, especially in long cable runs, but it requires an extra wire, increasing complexity and installation cost. Your choice depends on the balance between cost constraints and the need for measurement accuracy in your application.

2-wire RTD vs 3-wire RTD Infographic

electrown.com

electrown.com