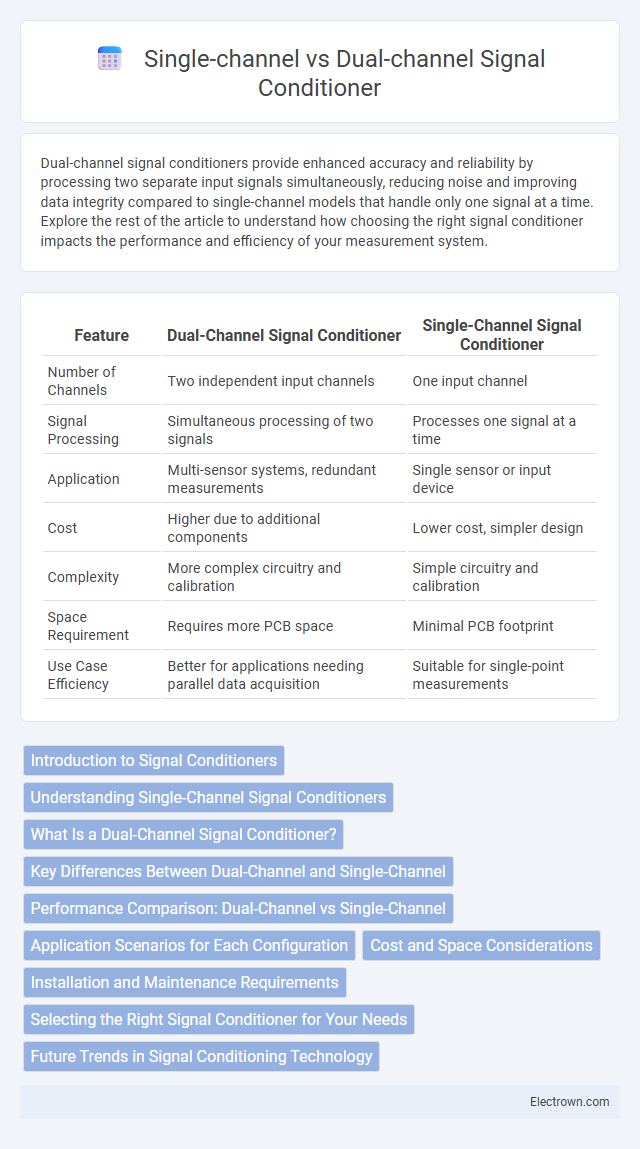

Dual-channel signal conditioners provide enhanced accuracy and reliability by processing two separate input signals simultaneously, reducing noise and improving data integrity compared to single-channel models that handle only one signal at a time. Explore the rest of the article to understand how choosing the right signal conditioner impacts the performance and efficiency of your measurement system.

Table of Comparison

| Feature | Dual-Channel Signal Conditioner | Single-Channel Signal Conditioner |

|---|---|---|

| Number of Channels | Two independent input channels | One input channel |

| Signal Processing | Simultaneous processing of two signals | Processes one signal at a time |

| Application | Multi-sensor systems, redundant measurements | Single sensor or input device |

| Cost | Higher due to additional components | Lower cost, simpler design |

| Complexity | More complex circuitry and calibration | Simple circuitry and calibration |

| Space Requirement | Requires more PCB space | Minimal PCB footprint |

| Use Case Efficiency | Better for applications needing parallel data acquisition | Suitable for single-point measurements |

Introduction to Signal Conditioners

Signal conditioners are essential devices that modify electrical signals to make them compatible with measurement or control systems. Dual-channel signal conditioners simultaneously process two input signals, offering synchronized data acquisition and reduced wiring complexity, while single-channel models handle one signal at a time, suitable for simpler applications. Your choice between dual-channel and single-channel depends on the complexity of your measurement needs and the requirement for signal isolation or multiplexing.

Understanding Single-Channel Signal Conditioners

Single-channel signal conditioners process input signals from a single sensor or source, ensuring precise amplification, filtering, and isolation for accurate data acquisition. These devices are ideal for applications requiring straightforward monitoring of one parameter, reducing complexity and cost. Your measurement system's accuracy depends heavily on selecting the right single-channel conditioner tailored to the specific signal type and range.

What Is a Dual-Channel Signal Conditioner?

A dual-channel signal conditioner processes two separate input signals simultaneously, enabling more efficient monitoring and data acquisition from multiple sensors. You benefit from improved accuracy and flexibility in industrial automation or instrumentation systems by handling diverse sensor outputs without needing multiple devices. Compared to single-channel conditioners, dual-channel models reduce equipment complexity and save space while maintaining signal integrity.

Key Differences Between Dual-Channel and Single-Channel

Dual-channel signal conditioners process two input signals simultaneously, offering enhanced accuracy and redundancy, while single-channel conditioners handle only one input signal at a time, making them simpler and more cost-effective. Dual-channel models excel in applications requiring fault tolerance and comparative analysis between signals, whereas single-channel units are ideal for straightforward, low-budget setups. Choosing the right conditioner depends on your specific needs for reliability, complexity, and budget constraints.

Performance Comparison: Dual-Channel vs Single-Channel

Dual-channel signal conditioners offer enhanced performance by simultaneously processing two input signals, improving accuracy and reducing noise interference compared to single-channel units. Single-channel conditioners are simpler and cost-effective but may introduce latency and lower signal integrity in multi-signal systems. The dual-channel design excels in applications requiring synchronized data acquisition and higher precision measurements.

Application Scenarios for Each Configuration

Dual-channel signal conditioners are ideal for applications requiring simultaneous measurement of two signals, such as differential sensor outputs, vibration monitoring systems, or temperature and humidity data logging in industrial automation. Single-channel signal conditioners are best suited for straightforward, isolated signal processing tasks like individual sensor calibration, pressure measurement in HVAC systems, or simple voltage signal conditioning in lab testing. Choosing between configurations depends on the complexity of signal acquisition, required accuracy, and real-time monitoring needs in fields like aerospace, manufacturing, or environmental monitoring.

Cost and Space Considerations

Dual-channel signal conditioners typically incur higher costs due to integrated circuitry handling two input signals, but they save valuable panel space compared to using two single-channel units. Single-channel conditioners tend to be less expensive individually but require more physical space and additional wiring complexity when multiple channels are needed. Your choice depends on budget constraints and available installation space, with dual-channel models offering a compact, potentially cost-effective solution for multi-signal applications.

Installation and Maintenance Requirements

Dual-channel signal conditioners typically require more complex installation due to the need for additional wiring and proper channel isolation, increasing initial setup time. Maintenance demands for dual-channel units are higher as technicians must troubleshoot and calibrate two channels separately, ensuring consistent performance and minimizing signal interference. Single-channel signal conditioners offer simpler installation and easier maintenance with fewer components, reducing downtime and labor costs during routine checks or repairs.

Selecting the Right Signal Conditioner for Your Needs

Choosing the right signal conditioner depends on your application's complexity and measurement accuracy requirements, where dual-channel signal conditioners offer simultaneous processing of two input signals for improved data correlation and efficiency. Single-channel signal conditioners, ideal for straightforward applications, provide dedicated signal isolation and conditioning for one input, reducing cost and system complexity. Evaluating factors such as required input channels, signal types, noise reduction capabilities, and budget constraints ensures optimal performance and reliability in your data acquisition system.

Future Trends in Signal Conditioning Technology

Dual-channel signal conditioners are evolving to support advanced data acquisition systems by providing enhanced accuracy, improved noise reduction, and simultaneous multi-sensor processing, which single-channel conditioners cannot match. Innovations like integrated IoT connectivity, AI-driven signal analysis, and miniaturized, low-power designs are driving the next generation of signal conditioning technology to enable smarter, real-time decision-making in industrial automation and remote monitoring applications. These future trends emphasize scalability and interoperability, ensuring seamless integration with Industry 4.0 frameworks and edge computing platforms.

Dual-channel vs Single-channel signal conditioner Infographic

electrown.com

electrown.com