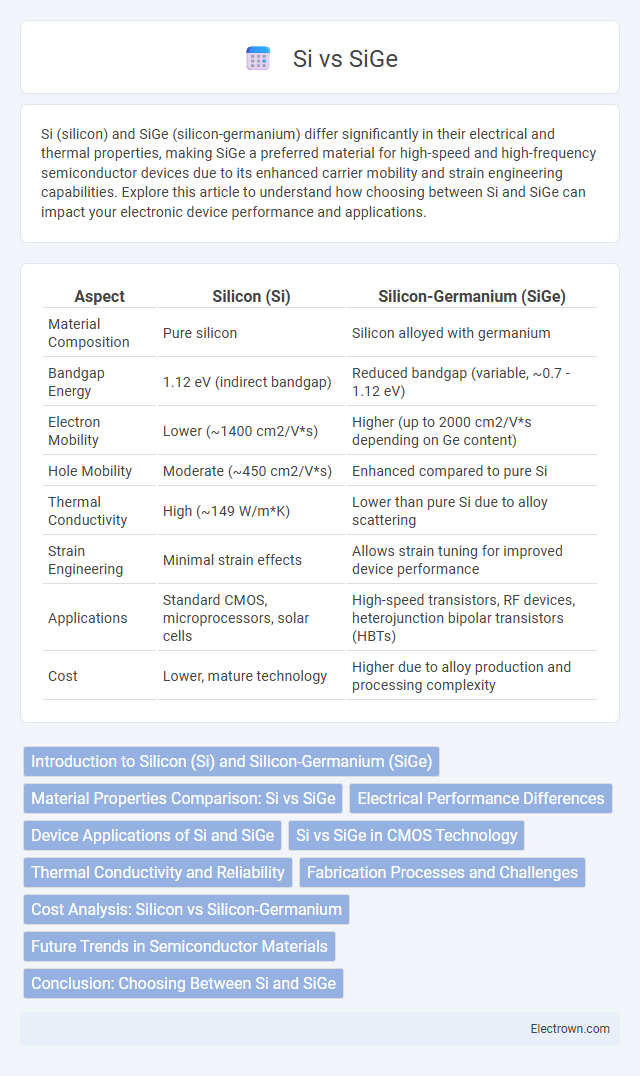

Si (silicon) and SiGe (silicon-germanium) differ significantly in their electrical and thermal properties, making SiGe a preferred material for high-speed and high-frequency semiconductor devices due to its enhanced carrier mobility and strain engineering capabilities. Explore this article to understand how choosing between Si and SiGe can impact your electronic device performance and applications.

Table of Comparison

| Aspect | Silicon (Si) | Silicon-Germanium (SiGe) |

|---|---|---|

| Material Composition | Pure silicon | Silicon alloyed with germanium |

| Bandgap Energy | 1.12 eV (indirect bandgap) | Reduced bandgap (variable, ~0.7 - 1.12 eV) |

| Electron Mobility | Lower (~1400 cm2/V*s) | Higher (up to 2000 cm2/V*s depending on Ge content) |

| Hole Mobility | Moderate (~450 cm2/V*s) | Enhanced compared to pure Si |

| Thermal Conductivity | High (~149 W/m*K) | Lower than pure Si due to alloy scattering |

| Strain Engineering | Minimal strain effects | Allows strain tuning for improved device performance |

| Applications | Standard CMOS, microprocessors, solar cells | High-speed transistors, RF devices, heterojunction bipolar transistors (HBTs) |

| Cost | Lower, mature technology | Higher due to alloy production and processing complexity |

Introduction to Silicon (Si) and Silicon-Germanium (SiGe)

Silicon (Si) is a fundamental semiconductor material widely used in electronic devices due to its excellent electrical properties and abundance. Silicon-Germanium (SiGe) is an alloy combining silicon and germanium, enabling enhanced carrier mobility and higher speed performance in integrated circuits compared to pure silicon. Choosing SiGe can improve your device's efficiency and frequency response in advanced semiconductor applications.

Material Properties Comparison: Si vs SiGe

Silicon (Si) offers excellent thermal conductivity and a stable crystal structure ideal for traditional semiconductor devices, while Silicon-Germanium (SiGe) provides enhanced carrier mobility and increased strain engineering flexibility, improving transistor performance and speed. SiGe alloys exhibit adjustable bandgap energies, enabling better control over electronic and optoelectronic properties compared to pure Si. Your choice between Si and SiGe can significantly impact device efficiency, especially in high-frequency analog and RF applications.

Electrical Performance Differences

Silicon-Germanium (SiGe) offers superior electrical performance compared to pure Silicon (Si) due to its higher electron mobility and lower base resistance, which enhances transistor speed and frequency response. SiGe heterojunction bipolar transistors (HBTs) enable better amplification and lower noise figures, making them ideal for high-frequency and RF applications. When optimizing Your semiconductor devices, choosing SiGe can result in faster switching speeds and improved power efficiency compared to traditional Si materials.

Device Applications of Si and SiGe

Silicon (Si) primarily dominates traditional semiconductor device applications such as microprocessors, memory chips, and power devices due to its well-established fabrication technology and cost-effectiveness. Silicon-Germanium (SiGe) alloys enhance device performance in high-frequency and high-speed applications like RF transistors, heterojunction bipolar transistors (HBTs), and photonic devices by offering improved carrier mobility and strain engineering benefits. SiGe's integration in compatible Si processes enables cost-effective, high-performance mixed-signal and communication systems, making it ideal for advanced wireless and optical communication technologies.

Si vs SiGe in CMOS Technology

SiGe (Silicon-Germanium) offers enhanced electron mobility compared to pure Si (Silicon), significantly improving the performance of CMOS technology by enabling faster switching speeds and lower power consumption. SiGe integration in CMOS devices allows for better strain engineering, which optimizes carrier transport properties and scaling beyond traditional Si limitations. Your advanced CMOS designs can achieve higher frequency operation and improved thermal stability using SiGe channels instead of conventional Si.

Thermal Conductivity and Reliability

Silicon (Si) exhibits higher thermal conductivity, approximately 150 W/m*K, compared to silicon-germanium (SiGe), which ranges around 30-50 W/m*K depending on the Ge content, making Si more efficient for heat dissipation in high-power applications. SiGe alloys often face increased thermal stress due to their lower thermal conductivity, potentially impacting device reliability over prolonged operation. Your design choice should weigh SiGe's enhanced electronic properties against its reduced thermal performance to ensure optimal device longevity.

Fabrication Processes and Challenges

SiGe fabrication involves epitaxial growth of silicon-germanium alloys on silicon wafers, requiring precise control of temperature and gas flow to prevent defects like dislocations and strain relaxation. Silicon processing benefits from mature CMOS technology with well-established doping, oxidation, and etching techniques, leading to high uniformity and yield. You face challenges in SiGe integration due to lattice mismatch and thermal expansion differences, complicating device reliability in heterojunction applications.

Cost Analysis: Silicon vs Silicon-Germanium

Silicon remains more cost-effective than silicon-germanium (SiGe) due to its abundant availability and mature manufacturing processes, leading to lower wafer and fabrication expenses. SiGe, while offering superior performance in high-frequency and analog applications, incurs higher production costs caused by complex epitaxial growth and doping techniques. For your semiconductor projects, silicon offers budget-friendly scalability, whereas SiGe delivers performance gains at a premium cost.

Future Trends in Semiconductor Materials

SiGe (Silicon-Germanium) alloys are gaining traction over traditional Si (Silicon) in semiconductor materials due to their superior electron mobility and thermal stability, which enhance device performance and energy efficiency. Future trends emphasize integrating SiGe with Si substrates to support high-speed, low-power applications in 5G, AI, and quantum computing technologies. Your choice of semiconductor material will significantly impact the scalability and performance of next-generation electronic devices.

Conclusion: Choosing Between Si and SiGe

Choosing between Silicon (Si) and Silicon-Germanium (SiGe) depends on your application's performance and cost requirements. SiGe offers superior high-frequency performance, improved carrier mobility, and enhanced speed, making it ideal for RF and high-speed analog circuits, while Si remains cost-effective and efficient for digital and mainstream semiconductor devices. Your decision should balance SiGe's advanced capabilities with Si's established manufacturing infrastructure and lower production costs.

Si vs SiGe Infographic

electrown.com

electrown.com