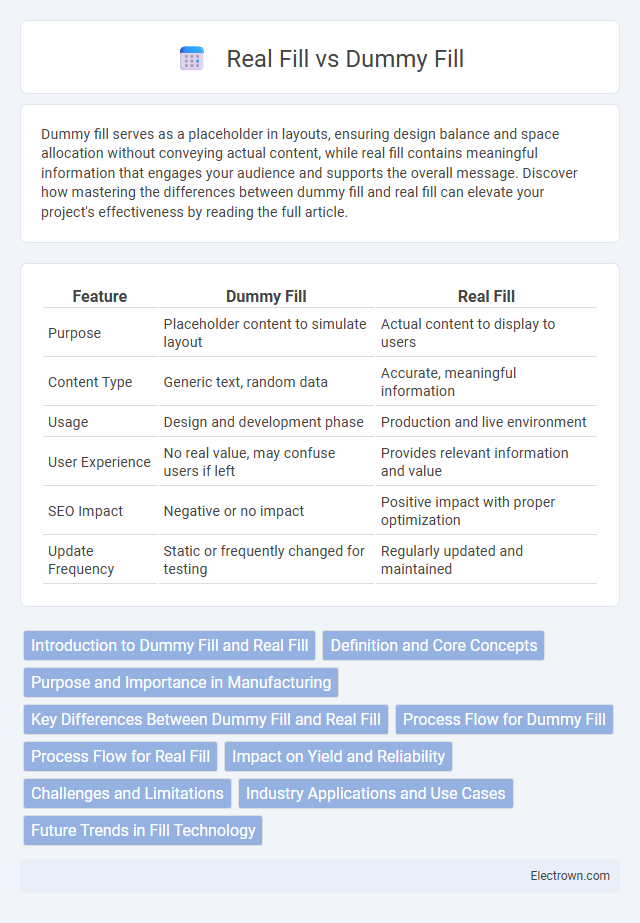

Dummy fill serves as a placeholder in layouts, ensuring design balance and space allocation without conveying actual content, while real fill contains meaningful information that engages your audience and supports the overall message. Discover how mastering the differences between dummy fill and real fill can elevate your project's effectiveness by reading the full article.

Table of Comparison

| Feature | Dummy Fill | Real Fill |

|---|---|---|

| Purpose | Placeholder content to simulate layout | Actual content to display to users |

| Content Type | Generic text, random data | Accurate, meaningful information |

| Usage | Design and development phase | Production and live environment |

| User Experience | No real value, may confuse users if left | Provides relevant information and value |

| SEO Impact | Negative or no impact | Positive impact with proper optimization |

| Update Frequency | Static or frequently changed for testing | Regularly updated and maintained |

Introduction to Dummy Fill and Real Fill

Dummy fill and real fill are terms used in semiconductor manufacturing to improve the planarization and uniformity of wafer surfaces during chemical mechanical polishing (CMP). Dummy fill involves adding non-functional patterns to areas of a chip to ensure even density, preventing dishing and erosion, while real fill consists of functional metal or features contributing directly to circuit operation. Understanding these techniques helps you optimize fabrication processes, enhancing device reliability and performance.

Definition and Core Concepts

Dummy fill refers to the temporary insertion of placeholder content or data used to simulate real input during testing or design phases, ensuring layout integrity and system functionality without relying on actual user information. Real fill involves populating fields or databases with genuine, verified data that reflects authentic user input or operational records, enabling accurate analysis and decision-making. Understanding the distinction between dummy fill and real fill is essential for effective data validation, user interface testing, and system reliability.

Purpose and Importance in Manufacturing

Dummy fill serves as a placeholder in manufacturing to maintain structural integrity, thermal balance, and layout symmetry during circuit board production, preventing defects such as warping or uneven heat distribution. Real fill involves using actual functional materials to complete a component or layer, ensuring proper electrical performance and product reliability. The distinction between dummy and real fills is crucial for optimizing manufacturing efficiency, reducing costs, and achieving high-quality end products.

Key Differences Between Dummy Fill and Real Fill

Dummy fill consists of placeholder data used in design or testing phases to simulate content without representing actual information, while real fill contains authentic, finalized data used in production environments. Key differences include the purpose--dummy fill aids in layout visualization and performance testing, whereas real fill ensures accuracy and functionality of the final product. Understanding these distinctions helps you avoid errors and ensures that your project transitions smoothly from concept to implementation.

Process Flow for Dummy Fill

The process flow for Dummy Fill involves inserting non-functional patterns into semiconductor layouts to ensure uniform density, which is critical for planarization during Chemical Mechanical Planarization (CMP). These dummy fills help minimize topographical variations and improve overall process reliability by preventing issues like dishing and erosion. Your designs benefit from enhanced manufacturability and yield through the strategic placement of dummy fills that complement the real functional patterns.

Process Flow for Real Fill

The process flow for Real Fill begins with the precise selection and preparation of materials to ensure compliance with project specifications and environmental standards. Next, real fill is systematically placed and compacted in layers using heavy machinery to achieve required density and stability, minimizing settlement risks. Continuous quality control checks, including moisture content and compaction testing, are integral to maintaining structural integrity and performance throughout the fill operation.

Impact on Yield and Reliability

Dummy fill and real fill significantly influence yield and reliability in semiconductor manufacturing; real fill involves placing active devices or functional elements that contribute to circuit operation, improving process uniformity and electrical performance. Dummy fill uses non-functional patterns to maintain planarity and density, which helps reduce dishing and erosion during chemical mechanical polishing (CMP), enhancing yield by preventing defects. The choice between dummy and real fill impacts device reliability, as real fill can introduce additional stress but also offers better electrical matching, while dummy fill primarily supports manufacturing stability without altering electrical characteristics.

Challenges and Limitations

Dummy fill materials often face challenges such as inconsistent compaction and moisture retention, which can compromise structural integrity in construction projects. Real fill provides better load-bearing capacity and stability but may be limited by availability, cost, and environmental concerns such as contamination or excessive excavation. Both methods require careful evaluation of soil properties and project specifications to avoid settlement issues and ensure long-term durability.

Industry Applications and Use Cases

Dummy fill materials are commonly used in electronics manufacturing for PCB testing, providing cost-effective and rapid prototyping to simulate real component behavior without the risk of damage. Real fill materials, such as plastics, metals, or resins, find extensive application in injection molding, automotive parts production, and aerospace components where durability and specific mechanical properties are essential. Both dummy and real fills serve critical roles in quality assurance, product development, and functional testing across industries like telecommunications, consumer electronics, automotive engineering, and aerospace manufacturing.

Future Trends in Fill Technology

Future trends in fill technology emphasize sustainability and precision, with real fill methods advancing through eco-friendly materials and smart sensors that optimize volume accuracy. Dummy fill remains prevalent in cost-effective, prototype applications but faces limitations as AI-driven real fill systems enhance efficiency and reduce waste. Integrating IoT and machine learning will empower your production lines to adapt dynamically, improving fill consistency and traceability in real-time.

Dummy Fill vs Real Fill Infographic

electrown.com

electrown.com