SC-70 and SOT-23 are two popular semiconductor packages often used for surface-mount devices; SC-70 is smaller and ideal for space-constrained applications, while SOT-23 offers better mechanical robustness and thermal performance. Explore the rest of the article to understand which package best suits your specific design needs and performance requirements.

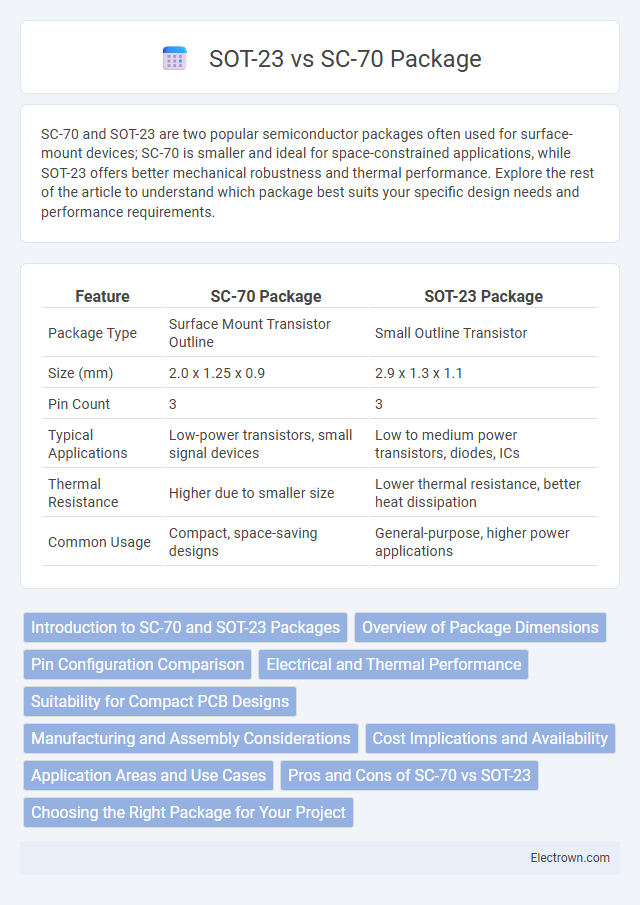

Table of Comparison

| Feature | SC-70 Package | SOT-23 Package |

|---|---|---|

| Package Type | Surface Mount Transistor Outline | Small Outline Transistor |

| Size (mm) | 2.0 x 1.25 x 0.9 | 2.9 x 1.3 x 1.1 |

| Pin Count | 3 | 3 |

| Typical Applications | Low-power transistors, small signal devices | Low to medium power transistors, diodes, ICs |

| Thermal Resistance | Higher due to smaller size | Lower thermal resistance, better heat dissipation |

| Common Usage | Compact, space-saving designs | General-purpose, higher power applications |

Introduction to SC-70 and SOT-23 Packages

The SC-70 and SOT-23 packages are both popular surface-mount device (SMD) encapsulations widely used in semiconductor components such as transistors and diodes. SC-70 offers a smaller footprint with dimensions typically around 2.0 x 1.25 mm, making it ideal for compact, space-sensitive applications, while SOT-23 measures approximately 2.9 x 1.3 mm and provides slightly better thermal dissipation capacity. Choosing between SC-70 and SOT-23 depends on your design requirements for size, power handling, and ease of assembly on printed circuit boards (PCBs).

Overview of Package Dimensions

SC-70 package dimensions typically measure approximately 2.0 mm in length, 1.25 mm in width, and 1.0 mm in height, making it a compact surface-mount device package mainly used for small-signal transistors and diodes. SOT-23 packages are slightly larger, approximately 2.9 mm long, 1.3 mm wide, and 1.1 mm high, offering more space for higher power dissipation and pin configuration options. Both packages support surface-mount technology but differ in footprint and thermal characteristics, influencing component selection based on size constraints and electrical requirements.

Pin Configuration Comparison

The SC-70 and SOT-23 packages differ significantly in pin configuration, with SC-70 typically featuring three leads arranged in a smaller footprint ideal for compact circuit designs. SOT-23 also has three leads but offers a slightly larger pad layout, improving soldering reliability and thermal dissipation. Understanding these pin configurations helps you select the appropriate package for your PCB design, balancing size constraints with assembly requirements.

Electrical and Thermal Performance

The SC-70 package typically offers lower thermal resistance than the SOT-23, enhancing heat dissipation efficiency for high-power applications. Electrically, SC-70 components generally exhibit lower parasitic inductance and capacitance due to their compact size, which improves high-frequency performance. SOT-23 packages provide slightly higher power ratings but with increased thermal impedance, making SC-70 preferable for minimizing thermal buildup in sensitive circuits.

Suitability for Compact PCB Designs

The SC-70 package offers a smaller footprint and lower profile compared to the SOT-23, making it highly suitable for ultra-compact PCB designs with stringent space constraints. While the SOT-23 provides slightly larger pad sizes that facilitate easier manual soldering, the SC-70's reduced dimensions optimize component density and enable more efficient use of limited board space. Designers prioritizing minimal PCB real estate and high component integration often select SC-70 to achieve compact and lightweight electronic assemblies.

Manufacturing and Assembly Considerations

SC-70 and SOT-23 packages differ significantly in manufacturing and assembly processes due to their size and lead configuration. The smaller SC-70 package enables higher component density on PCBs and is often favored for automated pick-and-place assembly, reducing assembly time and costs. Your choice between SC-70 and SOT-23 should consider equipment capabilities and soldering requirements to ensure reliable placement and thermal performance.

Cost Implications and Availability

SC-70 packages typically offer lower manufacturing costs due to their smaller size and simpler assembly process compared to SOT-23 packages, making them ideal for high-volume production runs. However, SOT-23 packages boast broader availability and higher demand across various applications, which can lead to better supply chain stability and more competitive pricing for smaller quantities. The choice between SC-70 and SOT-23 often depends on balancing the cost benefits of SC-70 against the greater market availability and sourcing flexibility of the SOT-23 package.

Application Areas and Use Cases

The SC-70 package is ideal for compact consumer electronics and portable devices due to its smaller size and lightweight design, which optimizes space and power efficiency. The SOT-23 package suits applications requiring moderate power dissipation and robust mechanical stability, such as automotive circuits, telecommunications, and industrial control systems. Your choice between SC-70 and SOT-23 depends on the specific requirements for size, thermal performance, and environmental durability in your project.

Pros and Cons of SC-70 vs SOT-23

The SC-70 package offers a smaller footprint and lower profile than the SOT-23, making it ideal for ultra-compact designs and applications with strict space constraints. However, the SOT-23 package provides better thermal dissipation and mechanical robustness, enhancing reliability in harsher environments and higher-power circuits. Your choice depends on whether space-saving or durability takes precedence in your circuit design.

Choosing the Right Package for Your Project

Selecting between SC-70 and SOT-23 packages depends on your project's size constraints and thermal requirements. SC-70 offers a smaller footprint ideal for space-critical applications, while SOT-23 provides better heat dissipation and mechanical stability for higher power components. Evaluating device size, power handling, and assembly process compatibility ensures optimal package selection for performance and reliability.

SC-70 vs SOT-23 package Infographic

electrown.com

electrown.com