Piezo buzzers use piezoelectric materials to generate sound through vibration, offering higher frequency ranges and lower power consumption, while magnetic buzzers rely on an electromagnetic coil and diaphragm to produce sound with typically louder volume but higher energy use. Explore the differences in detail and determine which buzzer suits your specific application by reading the rest of the article.

Table of Comparison

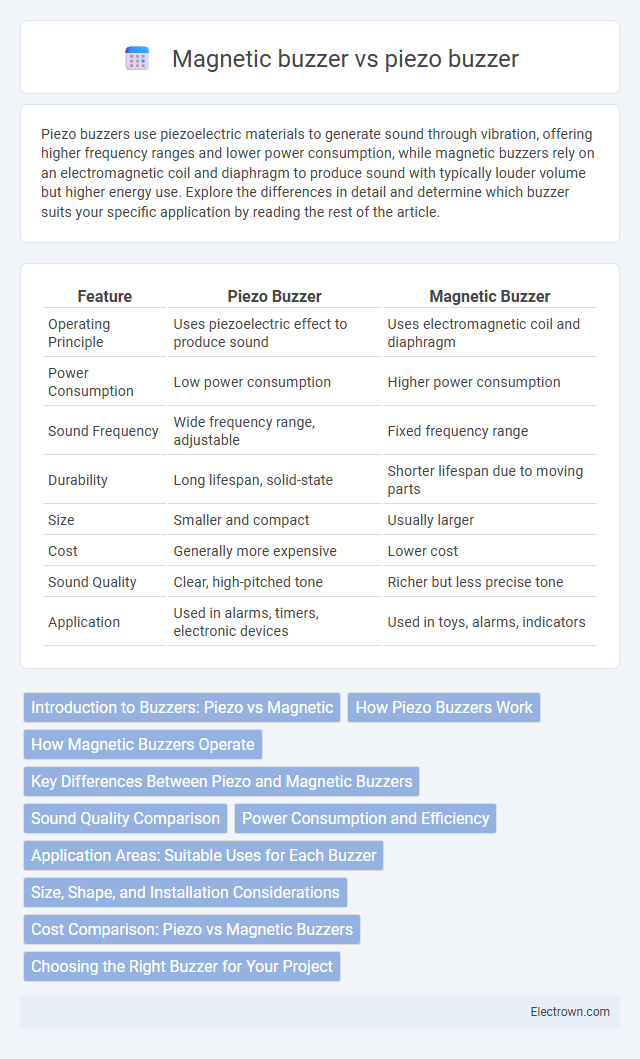

| Feature | Piezo Buzzer | Magnetic Buzzer |

|---|---|---|

| Operating Principle | Uses piezoelectric effect to produce sound | Uses electromagnetic coil and diaphragm |

| Power Consumption | Low power consumption | Higher power consumption |

| Sound Frequency | Wide frequency range, adjustable | Fixed frequency range |

| Durability | Long lifespan, solid-state | Shorter lifespan due to moving parts |

| Size | Smaller and compact | Usually larger |

| Cost | Generally more expensive | Lower cost |

| Sound Quality | Clear, high-pitched tone | Richer but less precise tone |

| Application | Used in alarms, timers, electronic devices | Used in toys, alarms, indicators |

Introduction to Buzzers: Piezo vs Magnetic

Piezo buzzers generate sound through the vibration of a piezoelectric crystal when an electric signal is applied, resulting in high-frequency tones with low power consumption. Magnetic buzzers use an electromagnetic coil and a diaphragm to produce sound, offering louder output but typically drawing more current. Your choice between piezo and magnetic buzzers depends on the required sound quality, volume, and power efficiency for your application.

How Piezo Buzzers Work

Piezo buzzers operate by using the piezoelectric effect, where an applied voltage causes a piezoelectric material to deform and produce sound vibrations. These buzzers typically feature a ceramic disc that oscillates at high frequencies, generating precise and efficient tones with low power consumption. Your choice of a piezo buzzer ensures reliable performance in applications requiring compact, lightweight, and stable audio signals.

How Magnetic Buzzers Operate

Magnetic buzzers operate using an electromagnet that creates a magnetic field when current passes through a coil, causing a diaphragm to vibrate and generate sound. The vibration frequency is determined by the electrical signal's frequency, allowing magnetic buzzers to produce a consistent tone. This electro-mechanical method makes magnetic buzzers ideal for applications requiring loud and robust audio signals, such as alarms and timers.

Key Differences Between Piezo and Magnetic Buzzers

Piezo buzzers use a piezoelectric element to produce sound by converting electrical signals into mechanical vibrations, resulting in a wide frequency range and low power consumption. Magnetic buzzers operate through an electromagnetic coil and diaphragm system, offering louder sound output but higher power requirements and limited frequency response. The choice between piezo and magnetic buzzers depends on factors such as desired sound frequency, volume, power efficiency, and application environment.

Sound Quality Comparison

Piezo buzzers produce clear, high-pitched sounds with rapid response times, ideal for precise audio signals. Magnetic buzzers generate richer, lower-frequency tones that offer better volume but less tonal clarity. Choosing the right buzzer depends on your need for sound quality precision versus loudness and tonal depth.

Power Consumption and Efficiency

Piezo buzzers typically consume less power and offer higher efficiency due to their ability to convert electrical energy directly into mechanical sound vibrations without requiring a coil. Magnetic buzzers use an electromagnetic coil that draws more current, resulting in higher power consumption and lower overall efficiency. Your choice of buzzer should consider power constraints, with piezo buzzers being preferable for battery-operated or energy-sensitive devices.

Application Areas: Suitable Uses for Each Buzzer

Piezo buzzers excel in applications requiring precise, high-frequency sound signals such as alarms, timers, and electronic beepers in medical devices or home appliances. Magnetic buzzers are ideal for low-frequency, robust sounds in automotive alerts, toys, and industrial equipment where louder noise and durability matter most. Your choice depends on whether you need clear, tonal signals or loud, power-efficient warnings for specific environments.

Size, Shape, and Installation Considerations

Piezo buzzers are typically smaller and more compact, often available in flat or disc shapes, making them ideal for applications with limited space and surface mounting requirements. Magnetic buzzers are usually larger, cylindrical, and bulkier, requiring more room and often necessitating through-hole installation on circuit boards. Installation considerations favor piezo buzzers in slim, low-profile devices, whereas magnetic buzzers suit designs where size is less constrained and robust mounting is needed.

Cost Comparison: Piezo vs Magnetic Buzzers

Piezo buzzers generally have a higher upfront cost than magnetic buzzers due to their solid-state construction and longer lifespan. Magnetic buzzers tend to be cheaper and easier to manufacture but may incur higher replacement costs over time due to mechanical wear. When choosing between the two, Your decision should weigh initial budget constraints against long-term reliability and maintenance expenses.

Choosing the Right Buzzer for Your Project

Piezo buzzers offer precise, high-frequency tones with low power consumption, making them ideal for compact electronic projects and applications requiring clear, consistent sound signals. Magnetic buzzers generate louder, lower-frequency sounds suitable for environments that need audible alerts over longer distances or in noisy settings. Selecting the right buzzer depends on sound clarity, volume requirements, power availability, and space constraints specific to your project's needs.

Piezo buzzer vs magnetic buzzer Infographic

electrown.com

electrown.com