Powder metallurgy involves producing metal parts by compacting and forming metal powders, while sintering is a key process within powder metallurgy where these compacted powders are heated below melting points to bond particles. Discover how understanding the differences between powder metallurgy and sintering can enhance your knowledge of advanced metal fabrication by reading the full article.

Table of Comparison

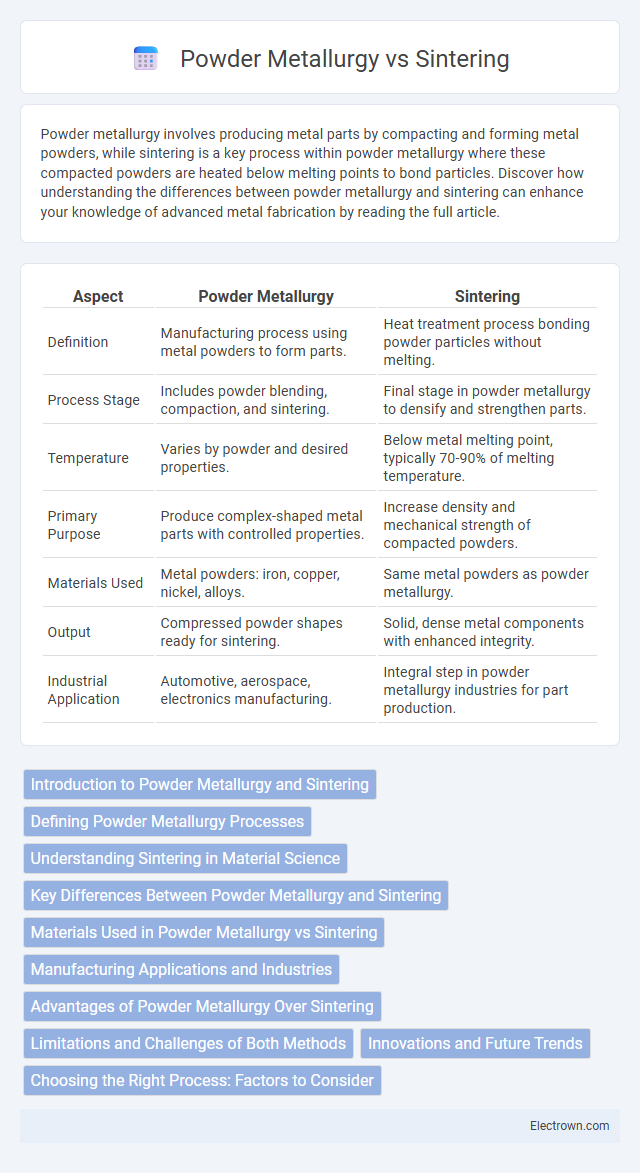

| Aspect | Powder Metallurgy | Sintering |

|---|---|---|

| Definition | Manufacturing process using metal powders to form parts. | Heat treatment process bonding powder particles without melting. |

| Process Stage | Includes powder blending, compaction, and sintering. | Final stage in powder metallurgy to densify and strengthen parts. |

| Temperature | Varies by powder and desired properties. | Below metal melting point, typically 70-90% of melting temperature. |

| Primary Purpose | Produce complex-shaped metal parts with controlled properties. | Increase density and mechanical strength of compacted powders. |

| Materials Used | Metal powders: iron, copper, nickel, alloys. | Same metal powders as powder metallurgy. |

| Output | Compressed powder shapes ready for sintering. | Solid, dense metal components with enhanced integrity. |

| Industrial Application | Automotive, aerospace, electronics manufacturing. | Integral step in powder metallurgy industries for part production. |

Introduction to Powder Metallurgy and Sintering

Powder metallurgy involves manufacturing metal parts by compacting metal powders and transforming them into solid components through heat treatment without melting the base material. Sintering, a key process within powder metallurgy, heats the compacted powder below its melting point to bond particles, enhancing mechanical strength and density. This method enables precise control of material properties and complex shapes, making it vital in automotive, aerospace, and medical industries.

Defining Powder Metallurgy Processes

Powder metallurgy processes involve the production of metal parts by compacting powdered metal and then heating it below the melting point in a controlled atmosphere, which enhances material properties while minimizing waste. Sintering is a critical step within powder metallurgy where heat causes the metal particles to bond at their contact points, increasing strength and structural integrity. Your choice between powder metallurgy and sintering depends on the desired precision, material characteristics, and application requirements of the final component.

Understanding Sintering in Material Science

Sintering is a crucial process in powder metallurgy that involves heating powdered materials below their melting point to bond particles into a solid mass, enhancing strength and structural integrity. This technique allows precise control over porosity, density, and mechanical properties, making it ideal for producing complex, high-performance components. Your understanding of sintering can significantly impact the optimization of material characteristics and manufacturing efficiency.

Key Differences Between Powder Metallurgy and Sintering

Powder metallurgy encompasses the entire process of producing metal parts from powdered metal, including powder production, blending, compacting, and sintering. Sintering specifically refers to the heat treatment step where compacted metal powders are heated below their melting point to bond particles and enhance mechanical properties. The key difference is that sintering is a crucial stage within powder metallurgy, which is a broader manufacturing technique involving multiple steps to create finished metal components.

Materials Used in Powder Metallurgy vs Sintering

Powder metallurgy primarily uses metallic powders such as iron, copper, aluminum, and nickel alloys to produce complex shapes with high precision and strength. In contrast, sintering is a thermal process applied to these powders, where heat below the melting point bonds particles together without liquefying, enhancing mechanical properties and density. Materials used in sintering include both metallic and ceramic powders, expanding its application range beyond powder metallurgy alone.

Manufacturing Applications and Industries

Powder metallurgy and sintering play critical roles in manufacturing applications across automotive, aerospace, and medical industries due to their ability to produce complex, high-strength, and wear-resistant components with minimal material waste. Powder metallurgy involves blending fine metal powders with additives before compaction, while sintering specifically refers to the heat treatment process that bonds these powders at temperatures below melting point, enhancing mechanical properties and structural integrity. These techniques enable mass production of engine parts, orthopedic implants, and cutting tools with precise dimensional tolerances and customized properties tailored to industry-specific demands.

Advantages of Powder Metallurgy Over Sintering

Powder metallurgy offers superior precision and material utilization compared to traditional sintering by enabling complex shapes with minimal waste through near-net-shape manufacturing. This process allows for enhanced control over alloy composition and microstructure, resulting in improved mechanical properties and reduced post-processing requirements. Your production efficiency benefits from faster manufacturing cycles and lower energy consumption, making powder metallurgy a cost-effective alternative to conventional sintering techniques.

Limitations and Challenges of Both Methods

Powder metallurgy faces challenges such as limited part size, complexity restrictions, and potential porosity affecting mechanical properties. Sintering often struggles with achieving full densification, leading to residual porosity that impacts strength and wear resistance. Both methods require precise control of particle size, temperature, and atmosphere to avoid defects like warping, grain growth, and contamination.

Innovations and Future Trends

Advancements in powder metallurgy are driving innovations such as additive manufacturing integration and nano-structured powders, enhancing material properties and manufacturing precision. Sintering techniques are evolving with the introduction of field-assisted sintering and microwave sintering, reducing cycle times and energy consumption. Your ability to leverage these future trends can lead to improved component performance and sustainable production in various industries.

Choosing the Right Process: Factors to Consider

Choosing between powder metallurgy and sintering depends on factors such as desired material properties, production volume, and component complexity. Powder metallurgy offers precise control over alloy composition and is ideal for high-volume manufacturing with minimal waste. Sintering excels in enhancing mechanical strength and density after powder compaction, making it suitable for components requiring superior structural integrity.

Powder metallurgy vs Sintering Infographic

electrown.com

electrown.com