SAMs (Self-Assembled Monolayers) provide organized molecular layers that modify surface properties with precision, while self-healing polymers actively repair damage to extend material lifespan. Explore the article to understand how SAMs and self-healing polymers differ and which one suits your applications best.

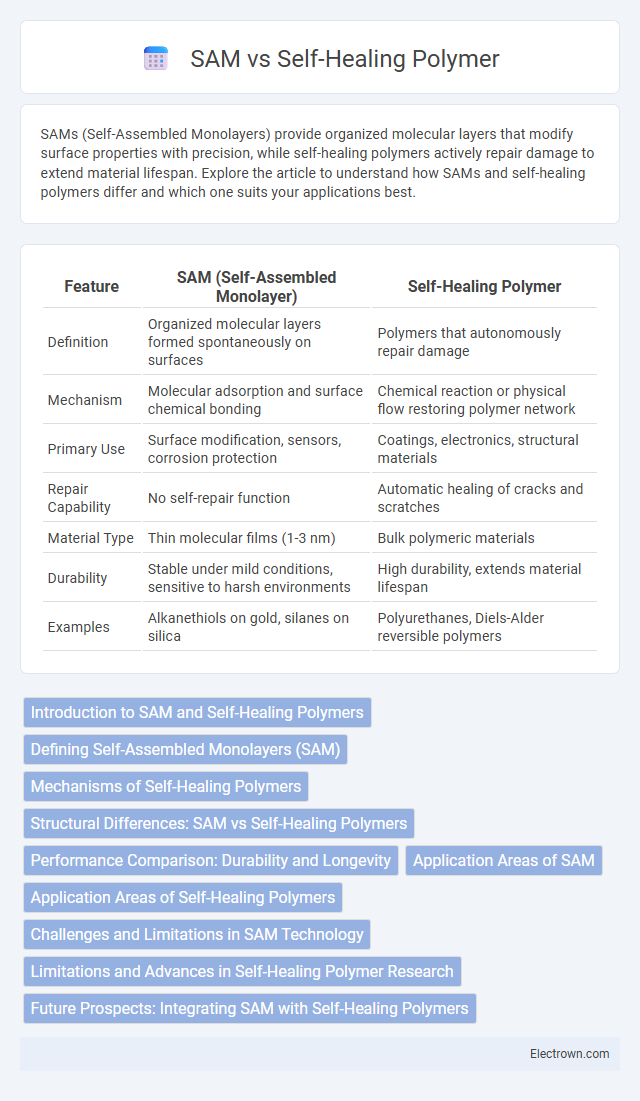

Table of Comparison

| Feature | SAM (Self-Assembled Monolayer) | Self-Healing Polymer |

|---|---|---|

| Definition | Organized molecular layers formed spontaneously on surfaces | Polymers that autonomously repair damage |

| Mechanism | Molecular adsorption and surface chemical bonding | Chemical reaction or physical flow restoring polymer network |

| Primary Use | Surface modification, sensors, corrosion protection | Coatings, electronics, structural materials |

| Repair Capability | No self-repair function | Automatic healing of cracks and scratches |

| Material Type | Thin molecular films (1-3 nm) | Bulk polymeric materials |

| Durability | Stable under mild conditions, sensitive to harsh environments | High durability, extends material lifespan |

| Examples | Alkanethiols on gold, silanes on silica | Polyurethanes, Diels-Alder reversible polymers |

Introduction to SAM and Self-Healing Polymers

Self-assembled monolayers (SAMs) are organized molecular assemblies formed by the spontaneous adsorption of amphiphilic molecules onto surfaces, creating well-defined, functionalized interfaces crucial for nanotechnology and sensor applications. Self-healing polymers are advanced materials engineered to autonomously repair damage through reversible chemical bonds or embedded healing agents, enhancing durability and lifespan in coatings, electronics, and structural components. Both technologies leverage molecular self-organization for surface engineering and material resilience, but SAMs focus on surface functionalization while self-healing polymers prioritize material recovery and longevity.

Defining Self-Assembled Monolayers (SAM)

Self-Assembled Monolayers (SAM) are organized molecular assemblies formed by the spontaneous adsorption of surfactant molecules onto surfaces, creating a highly ordered and stable monolayer. SAMs tailor surface properties such as wettability, adhesion, and corrosion resistance through precise control over molecular orientation and functional groups at the nanoscale. Unlike self-healing polymers, which autonomously repair physical damage, SAMs primarily modify surface chemistry without inherent restorative capabilities.

Mechanisms of Self-Healing Polymers

Self-healing polymers autonomously restore their structure and functionality through intrinsic mechanisms such as reversible covalent bonds, dynamic supramolecular interactions, and microencapsulated healing agents that respond to damage stimuli. These mechanisms enable the material to repair cracks and fractures by facilitating bond reformation or releasing healing compounds at the damaged site. Compared to Self-Assembled Monolayers (SAMs), which rely on ordered molecular adsorption on surfaces for functionality, self-healing polymers emphasize bulk material recovery through molecular mobility and chemical reactions within the polymer matrix.

Structural Differences: SAM vs Self-Healing Polymers

Self-assembled monolayers (SAMs) consist of a single layer of organized molecules adsorbed onto a substrate, forming highly ordered, nanoscale films with precise molecular orientation. Self-healing polymers are bulk materials characterized by dynamic covalent bonds or reversible interactions that enable autonomous repair of mechanical damage across their three-dimensional network. The key structural difference lies in SAMs being ultra-thin, surface-confined molecular assemblies, whereas self-healing polymers exhibit a cross-linked, volumetric architecture designed for macroscopic self-repair.

Performance Comparison: Durability and Longevity

Self-assembled monolayers (SAMs) offer precise molecular organization but generally lack the robust durability and longevity found in self-healing polymers, which can autonomously repair damage to maintain structural integrity. Self-healing polymers extend the lifespan of materials by restoring functionality after mechanical stress, reducing maintenance and replacement costs. When evaluating performance, your choice should consider the specific application environment, as self-healing polymers outperform SAMs in dynamic, wear-prone conditions requiring sustained durability.

Application Areas of SAM

SAM (Self-Assembled Monolayers) are widely utilized in nanotechnology, biosensors, and surface modification for improved adhesion and corrosion resistance. These monolayers create precise molecular coatings that enhance electronic device performance and enable selective immobilization of biomolecules in medical diagnostics. Your advancements in SAM enable tailored surface properties for applications in microelectronics, catalysis, and bioengineering.

Application Areas of Self-Healing Polymers

Self-healing polymers find extensive application in coatings, electronics, and biomedical devices, where their ability to repair damage autonomously enhances durability and longevity. These materials are vital in aerospace and automotive industries, improving safety and reducing maintenance costs by restoring mechanical integrity after impact or wear. You can leverage self-healing polymers in wearable technology and flexible electronics to ensure reliable performance and extended device lifespan.

Challenges and Limitations in SAM Technology

Self-assembled monolayers (SAMs) face challenges such as limited stability under harsh environmental conditions and difficulty achieving uniform coverage on complex surfaces. Their sensitivity to contamination and mechanical wear restricts long-term durability compared to self-healing polymers, which inherently restore structural integrity. Your choice between SAM and self-healing polymer technologies should consider these limitations in stability and repairability for specific applications.

Limitations and Advances in Self-Healing Polymer Research

Self-healing polymers exhibit limitations such as restricted healing efficiency, slow recovery times, and dependence on specific environmental conditions like temperature and humidity. Advances in self-healing polymer research include the development of dynamic covalent bonds, supramolecular interactions, and microvascular networks that enhance autonomous healing capabilities and mechanical robustness. Comparatively, self-assembled monolayers (SAMs) offer precise molecular organization but lack the bulk mechanical recovery properties inherent to self-healing polymers.

Future Prospects: Integrating SAM with Self-Healing Polymers

Integrating Self-Assembled Monolayers (SAM) with self-healing polymers holds promising potential for creating advanced materials with enhanced durability and responsiveness. This combination could enable precise molecular-level control of surface properties while allowing automatic repair of structural damage, extending the lifespan of coatings and electronic devices. Your future projects can benefit from this synergy by achieving both functional customization and self-repair capabilities in next-generation smart materials.

SAM vs self-healing polymer Infographic

electrown.com

electrown.com