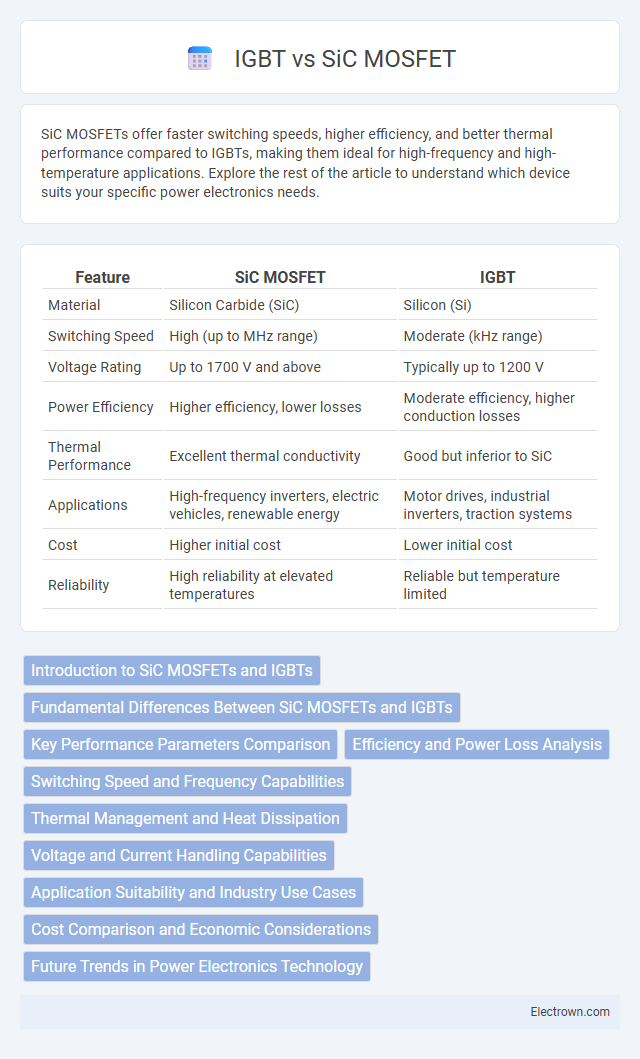

SiC MOSFETs offer faster switching speeds, higher efficiency, and better thermal performance compared to IGBTs, making them ideal for high-frequency and high-temperature applications. Explore the rest of the article to understand which device suits your specific power electronics needs.

Table of Comparison

| Feature | SiC MOSFET | IGBT |

|---|---|---|

| Material | Silicon Carbide (SiC) | Silicon (Si) |

| Switching Speed | High (up to MHz range) | Moderate (kHz range) |

| Voltage Rating | Up to 1700 V and above | Typically up to 1200 V |

| Power Efficiency | Higher efficiency, lower losses | Moderate efficiency, higher conduction losses |

| Thermal Performance | Excellent thermal conductivity | Good but inferior to SiC |

| Applications | High-frequency inverters, electric vehicles, renewable energy | Motor drives, industrial inverters, traction systems |

| Cost | Higher initial cost | Lower initial cost |

| Reliability | High reliability at elevated temperatures | Reliable but temperature limited |

Introduction to SiC MOSFETs and IGBTs

SiC MOSFETs feature wide bandgap semiconductor technology that offers higher efficiency, faster switching speeds, and better thermal performance compared to traditional IGBTs. IGBTs, or Insulated Gate Bipolar Transistors, have been widely used in power electronics for their robustness and cost-effectiveness but typically exhibit slower switching and higher losses. Your choice between SiC MOSFETs and IGBTs depends on the specific application requirements such as switching frequency, efficiency targets, and thermal management.

Fundamental Differences Between SiC MOSFETs and IGBTs

SiC MOSFETs and IGBTs differ fundamentally in their semiconductor materials and operation principles, with SiC MOSFETs utilizing silicon carbide for superior thermal conductivity and faster switching speeds. IGBTs, based on silicon, typically handle higher voltage applications but have slower switching rates and higher conduction losses compared to SiC devices. Understanding these core differences can help you select the right component for high-efficiency power electronics and demanding environments.

Key Performance Parameters Comparison

SiC MOSFETs offer faster switching speeds and lower on-resistance compared to IGBTs, enabling higher efficiency in power conversion applications. The higher breakdown voltage and superior thermal conductivity of SiC MOSFETs result in improved high-temperature operation and reliability. IGBTs, while traditionally favored for high-power, low-frequency applications, exhibit higher switching losses and slower response times relative to SiC MOSFETs.

Efficiency and Power Loss Analysis

SiC MOSFETs exhibit significantly higher efficiency than IGBTs due to their lower on-resistance and faster switching capabilities, which reduce conduction and switching losses. This results in lower power loss, especially at high frequencies and temperatures, making SiC MOSFETs ideal for high-efficiency power electronics applications. Your system can benefit from enhanced thermal performance and increased energy savings by selecting SiC MOSFETs over traditional IGBTs.

Switching Speed and Frequency Capabilities

SiC MOSFETs exhibit significantly higher switching speeds and can operate efficiently at frequencies exceeding 100 kHz, outperforming IGBTs, which typically switch below 20 kHz. The superior electron mobility and lower gate charge of SiC MOSFETs reduce switching losses and improve thermal performance, enabling higher frequency applications in power electronics. Your designs can benefit from enhanced efficiency and reduced system size when leveraging SiC MOSFETs for high-frequency switching tasks compared to traditional IGBTs.

Thermal Management and Heat Dissipation

SiC MOSFETs exhibit superior thermal conductivity and lower junction temperatures compared to IGBTs, enabling more efficient heat dissipation and reduced cooling requirements. Their higher thermal stability supports operation at elevated temperatures, which enhances system reliability and reduces the size and cost of thermal management components. In contrast, IGBTs generally require more robust cooling solutions due to higher on-state losses and heat generation during switching.

Voltage and Current Handling Capabilities

SiC MOSFETs offer superior voltage and current handling capabilities compared to traditional IGBTs, making them ideal for high-power applications exceeding 1.2 kV and tens of amperes. These devices benefit from higher electron mobility and wider bandgap materials, enabling better performance at elevated voltages and currents with lower switching losses and improved thermal efficiency. Your choice of SiC MOSFETs ensures enhanced power density and reliability in demanding environments where both voltage and current capacities are critical.

Application Suitability and Industry Use Cases

SiC MOSFETs excel in high-frequency, high-efficiency applications such as electric vehicle inverters, renewable energy systems, and aerospace power modules due to their fast switching and low conduction losses. IGBTs are preferred for heavy-duty industrial motors, traction systems, and welding equipment where robustness at medium frequencies and high voltages is crucial. Choosing between SiC MOSFET and IGBT depends on your application's switching speed, thermal management, and efficiency requirements within sectors like automotive, industrial automation, and energy.

Cost Comparison and Economic Considerations

SiC MOSFETs generally exhibit higher upfront costs compared to traditional IGBTs due to advanced semiconductor materials and manufacturing complexity. However, You can achieve long-term economic benefits with SiC MOSFETs through improved efficiency, reduced cooling requirements, and extended device lifespan, which lower operational expenses. In contrast, IGBTs offer lower initial investment but may incur higher energy losses and maintenance costs over time.

Future Trends in Power Electronics Technology

SiC MOSFETs are rapidly gaining traction in power electronics due to their superior efficiency, higher switching frequency, and thermal performance compared to traditional IGBTs, making them ideal for future applications in electric vehicles and renewable energy systems. The trend towards miniaturization and increased power density emphasizes the importance of SiC technology in reducing system size and energy losses. Your designs will benefit from embracing SiC MOSFETs as the industry shifts towards more efficient, high-performance power devices.

SiC MOSFET vs IGBT Infographic

electrown.com

electrown.com