SiO2 and Si3N4 are widely used dielectric materials in semiconductor devices, where SiO2 offers excellent thermal stability and insulating properties, while Si3N4 provides superior mechanical strength and acts as an effective diffusion barrier. Understanding the unique advantages and application-specific benefits of these dielectrics will help you make informed decisions for optimizing device performance; continue reading to explore their detailed characteristics and use cases.

Table of Comparison

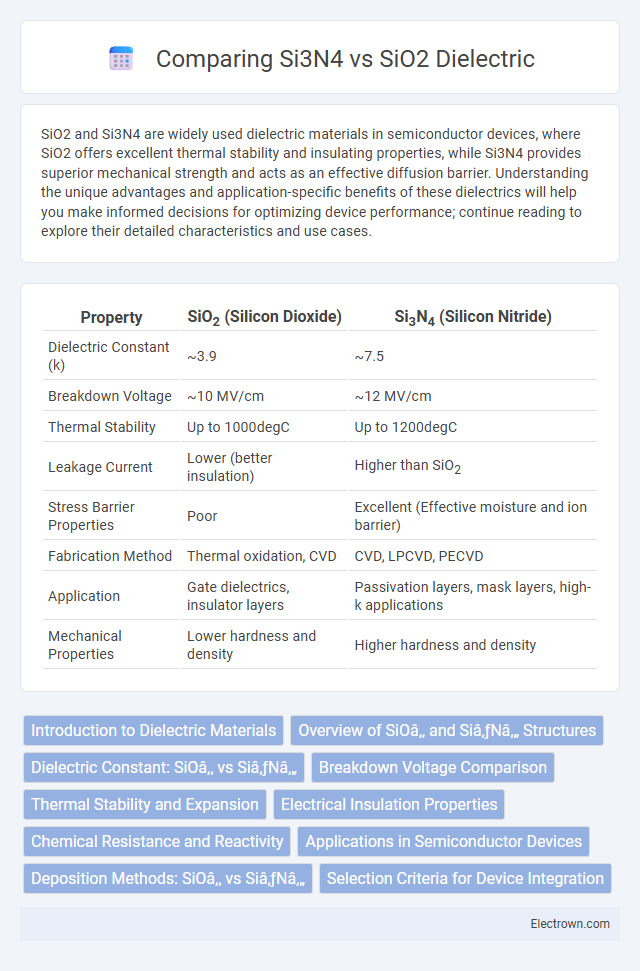

| Property | SiO2 (Silicon Dioxide) | Si3N4 (Silicon Nitride) |

|---|---|---|

| Dielectric Constant (k) | ~3.9 | ~7.5 |

| Breakdown Voltage | ~10 MV/cm | ~12 MV/cm |

| Thermal Stability | Up to 1000degC | Up to 1200degC |

| Leakage Current | Lower (better insulation) | Higher than SiO2 |

| Stress Barrier Properties | Poor | Excellent (Effective moisture and ion barrier) |

| Fabrication Method | Thermal oxidation, CVD | CVD, LPCVD, PECVD |

| Application | Gate dielectrics, insulator layers | Passivation layers, mask layers, high-k applications |

| Mechanical Properties | Lower hardness and density | Higher hardness and density |

Introduction to Dielectric Materials

SiO2 (silicon dioxide) and Si3N4 (silicon nitride) are critical dielectric materials in semiconductor manufacturing, each offering distinct electrical and thermal properties. SiO2 is renowned for its excellent insulating capability, high thermal stability, and compatibility with silicon substrates, making it a standard choice for gate oxides and interlayer dielectrics. Si3N4 exhibits superior mechanical strength, higher dielectric constant, and better resistance to diffusion and moisture, enhancing device reliability in high-performance and harsh-environment applications.

Overview of SiO₂ and Si₃N₄ Structures

SiO2 (silicon dioxide) has a tetrahedral network structure composed of silicon atoms covalently bonded to oxygen atoms, forming a robust and stable dielectric with a wide bandgap of about 9 eV. Si3N4 (silicon nitride) features a more complex covalent network where silicon atoms bond with nitrogen atoms, resulting in higher mechanical strength and thermal stability compared to SiO2. Your choice between these dielectrics depends on required properties such as dielectric constant, chemical resistance, and mechanical durability for specific semiconductor or MEMS applications.

Dielectric Constant: SiO₂ vs Si₃N₄

SiO2 (silicon dioxide) has a dielectric constant typically around 3.9, making it an excellent insulator with low permittivity for semiconductor applications. In contrast, Si3N4 (silicon nitride) exhibits a higher dielectric constant, usually between 7 and 8, providing better capacitance and charge storage capabilities. Your choice between SiO2 and Si3N4 dielectrics depends on the required dielectric constant and insulating properties for optimal device performance.

Breakdown Voltage Comparison

Silicon dioxide (SiO2) exhibits a breakdown voltage typically around 10 MV/cm, making it a robust dielectric material widely used in integrated circuits. Silicon nitride (Si3N4), however, demonstrates a higher breakdown voltage, often exceeding 12 MV/cm, attributed to its superior chemical stability and denser atomic structure. The elevated breakdown strength of Si3N4 renders it more suitable for high-voltage applications and environments requiring enhanced dielectric reliability.

Thermal Stability and Expansion

Silicon dioxide (SiO2) exhibits excellent thermal stability up to approximately 1100degC but has a relatively high coefficient of thermal expansion (CTE) around 0.5 x 10^-6 /K, which can lead to stress in semiconductor devices during thermal cycling. Silicon nitride (Si3N4) offers superior thermal stability, maintaining structural integrity beyond 1400degC, paired with a lower CTE of approximately 2.8 x 10^-6 /K, minimizing thermal mismatch with silicon substrates. The enhanced thermal properties of Si3N4 make it preferable for high-temperature applications requiring reduced mechanical stress and improved device reliability.

Electrical Insulation Properties

Silicon dioxide (SiO2) exhibits high electrical resistivity and excellent dielectric strength, making it a widely used insulator in semiconductor devices. Silicon nitride (Si3N4) offers superior breakdown voltage and greater resistance to leakage currents under high electric fields due to its higher dielectric constant and strong chemical bonds. Both materials provide effective electrical insulation, but Si3N4's enhanced dielectric properties make it preferable for high-performance and high-temperature applications.

Chemical Resistance and Reactivity

SiO2 (silicon dioxide) exhibits high chemical resistance to acids and solvents but is prone to etching in hydrofluoric acid, limiting its use in aggressive chemical environments. Si3N4 (silicon nitride) demonstrates superior chemical stability and lower reactivity, resisting corrosion from acids, alkalis, and oxidizers due to its dense, strong covalent bonds. This makes Si3N4 a preferred dielectric material in harsh chemical and high-temperature applications where SiO2 might degrade.

Applications in Semiconductor Devices

SiO2 and Si3N4 serve distinct roles as dielectrics in semiconductor devices, where SiO2 is predominantly used as a gate oxide and insulating layer due to its excellent thermal stability and native oxide formation on silicon. Si3N4 offers higher dielectric strength and acts as a superior diffusion barrier in MOSFETs and DRAM capacitors, enhancing device reliability and preventing dopant diffusion. The combination of SiO2 and Si3N4 in dual-layer stacks optimizes performance by balancing interface quality and electrical insulation in advanced integrated circuits.

Deposition Methods: SiO₂ vs Si₃N₄

SiO2 is commonly deposited using thermal oxidation and chemical vapor deposition (CVD) techniques, known for producing high-quality, uniform dielectric layers essential for semiconductor devices. Si3N4 is typically deposited via low-pressure CVD (LPCVD) or plasma-enhanced CVD (PECVD), offering superior mechanical strength and excellent barrier properties compared to SiO2. Your choice between SiO2 and Si3N4 deposition methods depends on device requirements such as thermal budget, dielectric constant, and stress tolerance.

Selection Criteria for Device Integration

SiO2 and Si3N4 dielectrics differ significantly in dielectric constant, thermal stability, and interface quality, crucial factors for device integration. SiO2 offers excellent interface passivation and low leakage currents, making it ideal for MOSFET gate oxides in CMOS technology. Si3N4 provides higher dielectric constant and superior mechanical strength, favored in applications requiring robust barriers and stress engineering; your choice depends on balancing electrical performance and process compatibility.

SiO2 vs Si3N4 dielectric Infographic

electrown.com

electrown.com