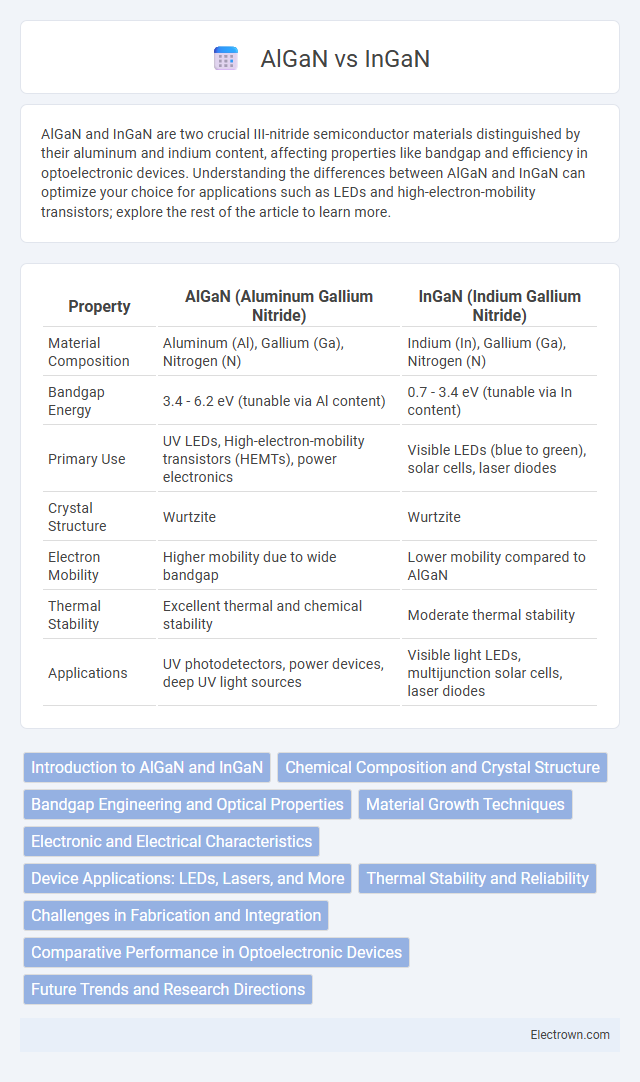

AlGaN and InGaN are two crucial III-nitride semiconductor materials distinguished by their aluminum and indium content, affecting properties like bandgap and efficiency in optoelectronic devices. Understanding the differences between AlGaN and InGaN can optimize your choice for applications such as LEDs and high-electron-mobility transistors; explore the rest of the article to learn more.

Table of Comparison

| Property | AlGaN (Aluminum Gallium Nitride) | InGaN (Indium Gallium Nitride) |

|---|---|---|

| Material Composition | Aluminum (Al), Gallium (Ga), Nitrogen (N) | Indium (In), Gallium (Ga), Nitrogen (N) |

| Bandgap Energy | 3.4 - 6.2 eV (tunable via Al content) | 0.7 - 3.4 eV (tunable via In content) |

| Primary Use | UV LEDs, High-electron-mobility transistors (HEMTs), power electronics | Visible LEDs (blue to green), solar cells, laser diodes |

| Crystal Structure | Wurtzite | Wurtzite |

| Electron Mobility | Higher mobility due to wide bandgap | Lower mobility compared to AlGaN |

| Thermal Stability | Excellent thermal and chemical stability | Moderate thermal stability |

| Applications | UV photodetectors, power devices, deep UV light sources | Visible light LEDs, multijunction solar cells, laser diodes |

Introduction to AlGaN and InGaN

AlGaN (Aluminum Gallium Nitride) and InGaN (Indium Gallium Nitride) are III-V semiconductor alloys widely used in optoelectronic devices like LEDs and laser diodes. AlGaN offers a wide bandgap ideal for ultraviolet and deep-ultraviolet light emission, while InGaN provides a direct bandgap suitable for visible light applications, especially blue and green wavelengths. Understanding the distinct electronic and optical properties of AlGaN and InGaN helps optimize Your device performance in specific lighting and communication applications.

Chemical Composition and Crystal Structure

AlGaN consists of aluminum, gallium, and nitrogen atoms arranged in a wurtzite crystal structure, offering a wide bandgap suitable for ultraviolet optoelectronic devices. InGaN is composed of indium, gallium, and nitrogen atoms with a similar wurtzite structure, but its smaller bandgap enables efficient emission in the visible light spectrum. Variations in atomic composition directly influence their lattice constants and bandgap energies, affecting device performance and material strain management.

Bandgap Engineering and Optical Properties

AlGaN and InGaN are III-nitride semiconductor alloys widely used in optoelectronic devices, with bandgap energies tunable across the UV to visible spectrum through precise compositional control. AlGaN offers a wide bandgap range from approximately 3.4 eV (GaN) to 6.2 eV (AlN), making it ideal for deep ultraviolet LEDs and UV photodetectors, while InGaN's bandgap varies from 0.7 eV (InN) to 3.4 eV (GaN), enabling efficient emission in the visible light range, especially blue and green LEDs. Optical properties differ significantly as AlGaN exhibits high transparency in the UV region with high exciton binding energy, whereas InGaN shows strong carrier localization effects due to indium composition fluctuations, enhancing radiative recombination efficiency in visible light devices.

Material Growth Techniques

AlGaN and InGaN are commonly grown using metal-organic chemical vapor deposition (MOCVD) and molecular beam epitaxy (MBE) techniques, which enable precise control over composition and thickness. AlGaN growth requires careful management of high aluminum content to prevent phase separation and cracking, often addressed by substrate selection and low-temperature buffer layers. InGaN growth challenges include indium incorporation and uniformity, necessitating optimized growth temperature and pressure conditions to achieve high-quality layers for optoelectronic applications.

Electronic and Electrical Characteristics

AlGaN and InGaN alloys exhibit distinct electronic and electrical characteristics crucial for optoelectronic applications. AlGaN boasts a wide bandgap ranging from 3.4 eV (GaN) up to 6.2 eV (AlN), enabling high breakdown voltages and high electron mobility, making it ideal for high-power and high-frequency devices. In contrast, InGaN has a narrower bandgap (0.7 to 3.4 eV depending on indium content) and exhibits strong carrier confinement and high radiative efficiency, essential for efficient light-emitting diodes (LEDs) and laser diodes, directly impacting Your device performance.

Device Applications: LEDs, Lasers, and More

AlGaN and InGaN semiconductors are crucial in optoelectronic devices, with AlGaN widely used in ultraviolet LEDs and laser diodes due to its wide bandgap properties, enabling high-efficiency UV emission. InGaN is dominant in visible LED applications, particularly blue and green LEDs and laser diodes, thanks to its tunable bandgap that covers a broad spectrum for high brightness and efficiency. Both materials are integral in advanced photonic devices, including power electronics and high-frequency transistors, expanding their application beyond traditional lighting and display technologies.

Thermal Stability and Reliability

AlGaN exhibits superior thermal stability compared to InGaN due to its wider bandgap and stronger chemical bonds, making it more suitable for high-temperature applications. In contrast, InGaN, while offering excellent optical properties, tends to suffer from thermal degradation and reliability issues under prolonged high-temperature stress. This makes AlGaN the preferred choice in devices requiring long-term operational stability and enhanced reliability in harsh thermal environments.

Challenges in Fabrication and Integration

Challenges in fabrication and integration of AlGaN and InGaN stem from their differing lattice constants and thermal expansion coefficients, causing significant strain and defects during epitaxial growth. AlGaN materials often face difficulties in achieving high-quality, crack-free layers due to high aluminum content, while InGaN suffers from phase separation and indium clustering, impacting uniformity and performance. Your device design must account for these material-specific challenges to optimize layer quality and ensure reliable integration in optoelectronic applications.

Comparative Performance in Optoelectronic Devices

AlGaN and InGaN are pivotal semiconductor materials in optoelectronic devices, with InGaN primarily excelling in high-efficiency blue and green LEDs due to its adjustable bandgap covering a wide spectral range from ultraviolet to visible light. AlGaN offers superior performance in ultraviolet optoelectronics thanks to its wider bandgap, making it ideal for UV LEDs and photodetectors. InGaN's higher internal quantum efficiency contrasts with AlGaN's enhanced thermal stability and radiation hardness, influencing device selection based on application-specific wavelength and durability requirements.

Future Trends and Research Directions

Future trends in AlGaN and InGaN research focus on enhancing efficiency and thermal stability for high-power and high-frequency applications. Emerging studies prioritize bandgap engineering and defect reduction to improve LED and laser diode performance in ultraviolet to visible light spectra. Advanced epitaxial growth techniques and nanostructuring are key research directions driving innovations in optoelectronic devices using AlGaN and InGaN alloys.

AlGaN vs InGaN Infographic

electrown.com

electrown.com