Spin coating offers uniform thin film deposition by rapidly spinning the substrate, ideal for small-scale applications requiring precise control, while doctor blading enables thicker, more consistent coatings over larger areas, suitable for industrial-scale production. Explore the detailed comparison to determine which technique best fits Your material processing needs.

Table of Comparison

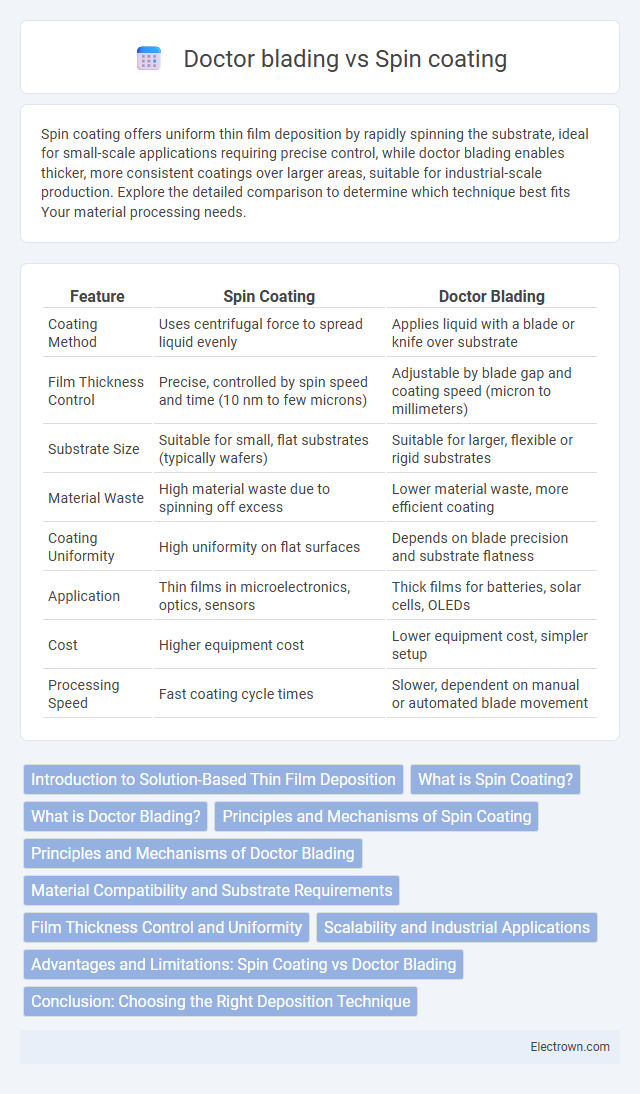

| Feature | Spin Coating | Doctor Blading |

|---|---|---|

| Coating Method | Uses centrifugal force to spread liquid evenly | Applies liquid with a blade or knife over substrate |

| Film Thickness Control | Precise, controlled by spin speed and time (10 nm to few microns) | Adjustable by blade gap and coating speed (micron to millimeters) |

| Substrate Size | Suitable for small, flat substrates (typically wafers) | Suitable for larger, flexible or rigid substrates |

| Material Waste | High material waste due to spinning off excess | Lower material waste, more efficient coating |

| Coating Uniformity | High uniformity on flat surfaces | Depends on blade precision and substrate flatness |

| Application | Thin films in microelectronics, optics, sensors | Thick films for batteries, solar cells, OLEDs |

| Cost | Higher equipment cost | Lower equipment cost, simpler setup |

| Processing Speed | Fast coating cycle times | Slower, dependent on manual or automated blade movement |

Introduction to Solution-Based Thin Film Deposition

Solution-based thin film deposition techniques such as spin coating and doctor blading enable uniform coating of materials on substrates by depositing liquid precursor solutions. Spin coating utilizes centrifugal force to spread the solution evenly and achieve thin, uniform films typically below a few micrometers in thickness, making it ideal for high-precision applications. Doctor blading, also known as blade coating, involves spreading the solution with a blade at a controlled gap, allowing for thicker films and scalable production suited for flexible electronics and large-area coatings.

What is Spin Coating?

Spin coating is a technique used to apply uniform thin films onto flat substrates by depositing a liquid solution and rapidly spinning the substrate to spread the material evenly through centrifugal force. This method is widely favored in semiconductor manufacturing and research for its ability to produce consistent film thicknesses ranging from a few nanometers to micrometers. Understanding spin coating can help you achieve precise control over film uniformity and thickness, making it ideal for applications requiring high-quality coatings.

What is Doctor Blading?

Doctor blading is a precise thin-film coating technique that spreads a controlled amount of liquid or slurry across a substrate using a blade, ensuring uniform thickness. Unlike spin coating, which relies on centrifugal force to distribute material, doctor blading offers better scalability for large areas and thicker coatings. Your choice between these methods depends on the desired film thickness, uniformity, and substrate size for applications such as photovoltaics or printed electronics.

Principles and Mechanisms of Spin Coating

Spin coating operates by depositing a liquid film on a substrate that rapidly spins, utilizing centrifugal force to spread the material uniformly and control film thickness through rotational speed and solution viscosity. This technique ensures consistent, thin coatings essential for electronic and optical applications. Understanding the flow dynamics and evaporation rate during spin coating helps optimize your film quality and uniformity.

Principles and Mechanisms of Doctor Blading

Doctor blading is a film coating technique where a blade spreads a liquid material evenly across a substrate through controlled mechanical pressure and a fixed gap height. Unlike spin coating, which uses centrifugal force for film uniformity, doctor blading relies on the precise movement of the blade to regulate film thickness and wetting behavior. Your material's viscosity and blade speed critically influence the coating's uniformity and thickness during the doctor blading process.

Material Compatibility and Substrate Requirements

Spin coating excels in creating uniform thin films on flat, rigid substrates like silicon wafers and glass, but it struggles with high-viscosity materials and non-uniform surfaces. Doctor blading handles a wider range of material viscosities, including thick pastes and polymers, and is more adaptable to flexible or textured substrates. Your choice depends on the material's flow characteristics and the substrate's surface properties to ensure optimal coating quality.

Film Thickness Control and Uniformity

Spin coating offers precise film thickness control through adjustable spin speed and time, producing highly uniform thin films ideal for electronics and optics. Doctor blading allows better control over thicker film deposition by varying the blade gap and solution viscosity, though uniformity can be influenced by substrate flatness and blade speed. Choosing between these methods depends on your required film thickness and uniformity, with spin coating excelling in nanoscale precision and doctor blading suited for larger, consistent coatings.

Scalability and Industrial Applications

Spin coating offers high uniformity but faces limitations in scalability for large-area industrial applications due to its small batch size and substrate size constraints. Doctor blading excels in scalability, enabling continuous processing of large substrates with controlled film thickness, making it ideal for industrial production of flexible electronics and coatings. Your choice depends on the balance between precision in thin film uniformity and the need for large-scale manufacturing efficiency.

Advantages and Limitations: Spin Coating vs Doctor Blading

Spin coating offers uniform thin films with excellent thickness control, ideal for small substrates but wastes material and lacks scalability for large areas. Doctor blading enables coating of larger surfaces with adjustable film thickness using less material but may produce less uniform layers and surface defects. Your choice depends on balancing precision needs and substrate size for optimal coating performance.

Conclusion: Choosing the Right Deposition Technique

Spin coating offers uniform thin films ideal for small substrates and precise layer control, whereas doctor blading suits larger areas with adjustable film thickness and cost-effectiveness for scalable production. The choice depends on factors like substrate size, desired film uniformity, material viscosity, and production volume. For high-precision, uniform coatings on small samples, spin coating is preferred; for large-area coatings and thicker layers, doctor blading provides better scalability and efficiency.

Spin coating vs Doctor blading Infographic

electrown.com

electrown.com