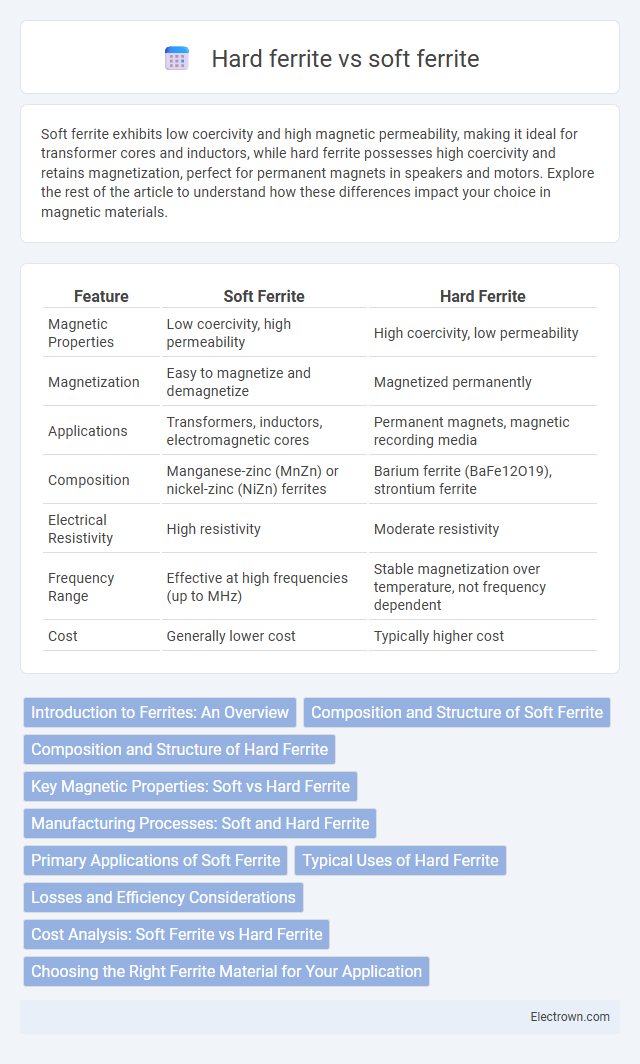

Soft ferrite exhibits low coercivity and high magnetic permeability, making it ideal for transformer cores and inductors, while hard ferrite possesses high coercivity and retains magnetization, perfect for permanent magnets in speakers and motors. Explore the rest of the article to understand how these differences impact your choice in magnetic materials.

Table of Comparison

| Feature | Soft Ferrite | Hard Ferrite |

|---|---|---|

| Magnetic Properties | Low coercivity, high permeability | High coercivity, low permeability |

| Magnetization | Easy to magnetize and demagnetize | Magnetized permanently |

| Applications | Transformers, inductors, electromagnetic cores | Permanent magnets, magnetic recording media |

| Composition | Manganese-zinc (MnZn) or nickel-zinc (NiZn) ferrites | Barium ferrite (BaFe12O19), strontium ferrite |

| Electrical Resistivity | High resistivity | Moderate resistivity |

| Frequency Range | Effective at high frequencies (up to MHz) | Stable magnetization over temperature, not frequency dependent |

| Cost | Generally lower cost | Typically higher cost |

Introduction to Ferrites: An Overview

Soft ferrites exhibit high magnetic permeability and low coercivity, making them ideal for applications like transformers and inductors where magnetic reversal is frequent. Hard ferrites possess high coercivity and remanence, suitable for permanent magnets in motors and loudspeakers due to their ability to retain magnetization. Understanding these magnetic properties helps you select the appropriate ferrite type for efficient performance in electronic and electromagnetic devices.

Composition and Structure of Soft Ferrite

Soft ferrite primarily consists of iron oxide combined with small amounts of metallic elements such as manganese, zinc, or nickel, forming a polycrystalline structure with low coercivity. Its composition enables magnetic domains to realign easily under an external magnetic field, making it ideal for high-frequency applications like inductors and transformers. Your choice of soft ferrite hinges on its tailored chemical makeup and grain structure, ensuring minimal energy loss and efficient magnetic performance.

Composition and Structure of Hard Ferrite

Hard ferrite is primarily composed of barium or strontium hexaferrite (BaFe12O19 or SrFe12O19), featuring a rigid crystalline structure with high magnetic anisotropy. The hexagonal crystal lattice in hard ferrite imparts strong coercivity and permanent magnet properties, distinguishing it from the more easily magnetized and demagnetized soft ferrite. This specific composition and microstructure enable hard ferrite to maintain stable magnetization under high temperature and demagnetizing fields.

Key Magnetic Properties: Soft vs Hard Ferrite

Soft ferrite exhibits high magnetic permeability, low coercivity, and minimal hysteresis loss, making it ideal for high-frequency applications such as inductors and transformers. Hard ferrite, in contrast, has high coercivity, significant retentivity, and a stable magnetic remanence, suitable for permanent magnets in motors and loudspeakers. The key magnetic property difference lies in soft ferrite's ease of magnetization reversal versus hard ferrite's resistance to demagnetization.

Manufacturing Processes: Soft and Hard Ferrite

Soft ferrite manufacturing involves powder metallurgy techniques such as pressing and sintering fine, mixed metal oxides to achieve high magnetic permeability and low coercivity for efficient electromagnetic applications. Hard ferrite production typically includes sintering strontium or barium carbonate with iron oxide at high temperatures to form a rigid, magnetically stable ceramic with high coercivity and permanent magnet properties. Understanding these processes helps you select the appropriate ferrite type for applications requiring either easy magnetization reversibility or strong, long-lasting magnetic performance.

Primary Applications of Soft Ferrite

Soft ferrite primarily serves in electromagnetic applications such as transformers, inductors, and antennas due to its high magnetic permeability and low coercivity, enabling efficient energy transfer and minimal power loss. These materials are ideal for high-frequency circuits found in power supplies, signal processing, and communication devices. Your choice of soft ferrite can significantly enhance the performance and reliability of electronic components in these applications.

Typical Uses of Hard Ferrite

Hard ferrite magnets are widely used in applications requiring strong, permanent magnetic properties such as refrigerator magnets, loudspeakers, and small electric motors. Their high coercivity and resistance to demagnetization make them ideal for data storage devices and magnetic separators. You will find hard ferrite materials essential in producing cost-effective, durable magnets for consumer electronics and automotive components.

Losses and Efficiency Considerations

Soft ferrite materials exhibit low core losses and high magnetic permeability, making them ideal for high-frequency transformer and inductor applications where efficiency is critical. Hard ferrite magnets, characterized by high coercivity and irreversible magnetization, tend to have higher energy losses due to hysteresis, which can reduce overall device efficiency in dynamic magnetic environments. Choosing the right ferrite type impacts your system's power loss profile and thus directly influences the efficiency and thermal management requirements.

Cost Analysis: Soft Ferrite vs Hard Ferrite

Soft ferrite magnets generally have lower production costs due to simpler manufacturing processes and abundant raw materials like iron oxide and manganese. Hard ferrite magnets, while slightly more expensive, offer higher coercivity and magnetic strength, justifying the cost in applications requiring strong permanent magnets. Your choice depends on budget constraints and performance needs, balancing initial expenditure with long-term functionality.

Choosing the Right Ferrite Material for Your Application

Selecting the right ferrite material depends on your application's magnetic properties and performance requirements. Soft ferrites exhibit high magnetic permeability and low coercivity, making them ideal for transformers, inductors, and EMI suppression where efficient magnetic response and low energy loss are critical. Hard ferrites provide high coercivity and permanent magnetization, suitable for motors, sensors, and magnetic storage devices requiring stable, strong magnetic fields.

soft ferrite vs hard ferrite Infographic

electrown.com

electrown.com