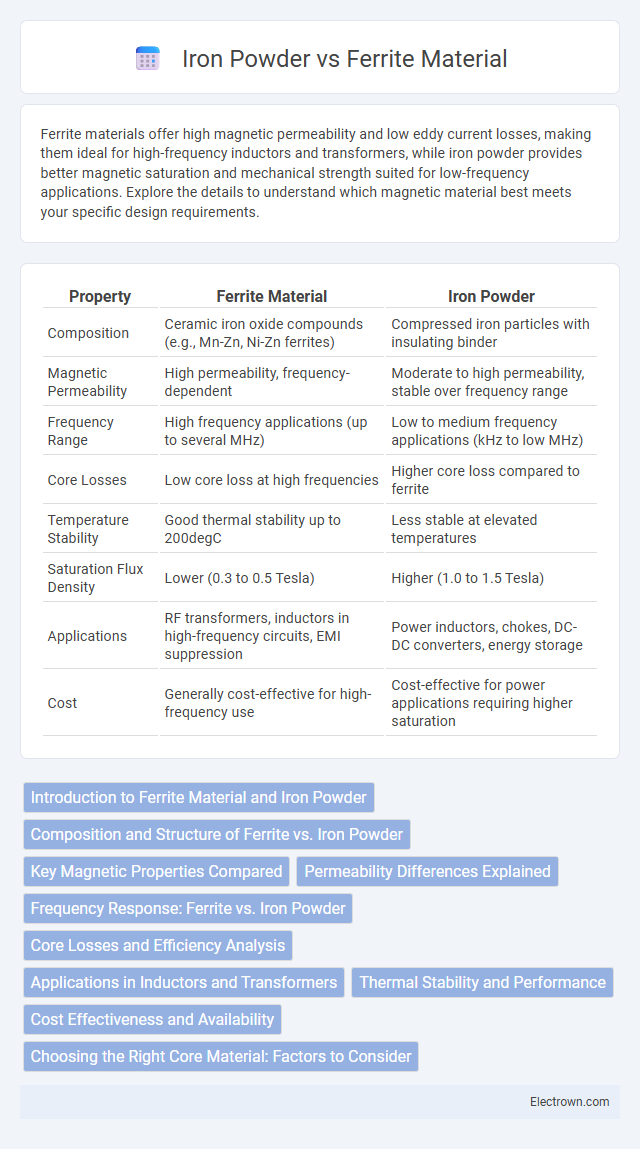

Ferrite materials offer high magnetic permeability and low eddy current losses, making them ideal for high-frequency inductors and transformers, while iron powder provides better magnetic saturation and mechanical strength suited for low-frequency applications. Explore the details to understand which magnetic material best meets your specific design requirements.

Table of Comparison

| Property | Ferrite Material | Iron Powder |

|---|---|---|

| Composition | Ceramic iron oxide compounds (e.g., Mn-Zn, Ni-Zn ferrites) | Compressed iron particles with insulating binder |

| Magnetic Permeability | High permeability, frequency-dependent | Moderate to high permeability, stable over frequency range |

| Frequency Range | High frequency applications (up to several MHz) | Low to medium frequency applications (kHz to low MHz) |

| Core Losses | Low core loss at high frequencies | Higher core loss compared to ferrite |

| Temperature Stability | Good thermal stability up to 200degC | Less stable at elevated temperatures |

| Saturation Flux Density | Lower (0.3 to 0.5 Tesla) | Higher (1.0 to 1.5 Tesla) |

| Applications | RF transformers, inductors in high-frequency circuits, EMI suppression | Power inductors, chokes, DC-DC converters, energy storage |

| Cost | Generally cost-effective for high-frequency use | Cost-effective for power applications requiring higher saturation |

Introduction to Ferrite Material and Iron Powder

Ferrite material consists of ceramic compounds primarily made from iron oxide combined with metallic elements, known for high magnetic permeability and low electrical conductivity, making it ideal in inductors and transformers. Iron powder involves small particles of pure iron used in soft magnetic components due to its high saturation magnetization and good thermal conductivity. Understanding the unique magnetic and electrical properties of ferrite and iron powder helps you select the right material for efficient electromagnetic applications.

Composition and Structure of Ferrite vs. Iron Powder

Ferrite material consists primarily of iron oxide combined with metallic elements such as manganese, zinc, or nickel, forming a ceramic-like crystalline structure that provides high electrical resistivity and magnetic permeability. In contrast, iron powder is composed of fine particles of pure or nearly pure iron with a metallic crystalline structure, offering high magnetic saturation but lower resistivity. Understanding the distinct composition and microstructure of ferrite versus iron powder helps you select the ideal magnetic core material for applications requiring low eddy current losses or high magnetic flux density.

Key Magnetic Properties Compared

Ferrite materials typically exhibit higher electrical resistivity and lower core losses compared to iron powder, making them ideal for high-frequency applications such as inductors and transformers. Iron powder, on the other hand, offers better saturation magnetization and mechanical robustness, which benefits applications requiring high magnetic flux density and structural strength. Understanding these key magnetic properties allows your design to optimize performance based on frequency range, power efficiency, and mechanical durability needs.

Permeability Differences Explained

Ferrite materials exhibit higher magnetic permeability than iron powder due to their ceramic composition, which provides superior magnetic domain alignment and reduced eddy current losses. Iron powder cores have lower permeability because their particulate structure introduces air gaps, limiting magnetic flux density and increasing resistive losses. Understanding these permeability differences helps optimize your inductor or transformer design for efficiency and frequency response.

Frequency Response: Ferrite vs. Iron Powder

Ferrite materials exhibit superior performance at higher frequencies, typically above 1 MHz, due to their low eddy current losses and high electrical resistivity, making them ideal for RF transformers and inductors. Iron powder cores excel in applications operating below 100 kHz, where their distributed air gaps and lower permeability reduce core losses and prevent saturation. The frequency response comparison highlights ferrite's dominance in high-frequency circuits and iron powder's suitability for low-frequency power applications.

Core Losses and Efficiency Analysis

Ferrite materials typically exhibit lower core losses at high frequencies compared to iron powder, resulting in improved energy efficiency for RF and high-frequency transformer applications. Iron powder cores demonstrate higher core losses due to eddy currents, which makes them less efficient but provides better saturation characteristics for power inductors. Your choice of core material directly impacts transformer efficiency, especially where core losses dominate operational performance.

Applications in Inductors and Transformers

Ferrite materials offer high magnetic permeability and low core losses at high frequencies, making them ideal for inductors and transformers in switching power supplies and RF applications. Iron powder cores provide distributed air gaps, which reduce core saturation and are suitable for inductors in power electronics and EMI filters requiring stable inductance under varying currents. Choosing the right core depends on your application's frequency range, power level, and efficiency needs.

Thermal Stability and Performance

Ferrite materials exhibit superior thermal stability with Curie temperatures typically above 450degC, making them ideal for high-frequency applications where consistent magnetic performance is critical. In contrast, iron powder has lower thermal stability, often degrading magnetically above 200degC, which limits its use to lower temperature environments. Ferrites maintain minimal core losses and stable permeability at elevated temperatures, whereas iron powder cores experience increased loss and performance decline under thermal stress.

Cost Effectiveness and Availability

Ferrite materials typically offer higher cost-effectiveness due to their lower raw material expenses and simpler manufacturing processes compared to iron powder. Ferrite is widely available as it is produced from abundant ceramic compounds, making it a reliable choice for mass production. Your selection between ferrite and iron powder should consider both cost constraints and the supply chain stability to ensure optimal availability and budget performance.

Choosing the Right Core Material: Factors to Consider

Choosing between ferrite material and iron powder cores depends on factors like operating frequency, magnetic permeability, and core losses. Ferrite cores excel in high-frequency applications due to their low eddy current losses and high resistivity, while iron powder cores perform better in low-frequency, high-current scenarios with superior saturation flux density. Your application's thermal stability, permeability range, and cost constraints will ultimately determine the optimal core material choice.

Ferrite material vs Iron powder Infographic

electrown.com

electrown.com