Solder mask protects the PCB by insulating copper traces and preventing solder bridging during assembly, while legend ink provides visible markings for component identification and troubleshooting. Explore the article to understand how choosing the right coating enhances your PCB's performance and reliability.

Table of Comparison

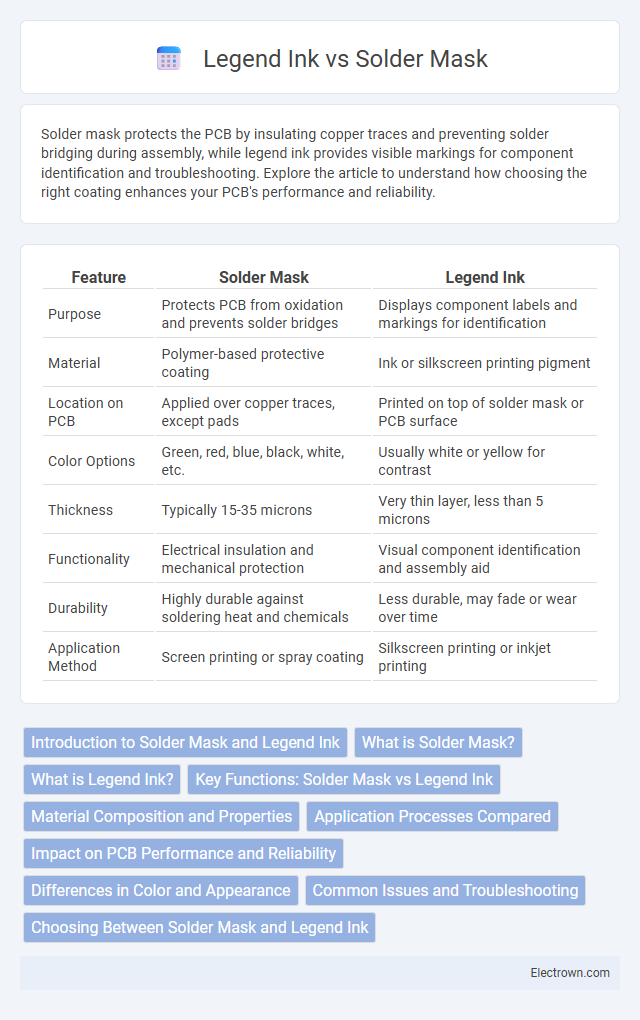

| Feature | Solder Mask | Legend Ink |

|---|---|---|

| Purpose | Protects PCB from oxidation and prevents solder bridges | Displays component labels and markings for identification |

| Material | Polymer-based protective coating | Ink or silkscreen printing pigment |

| Location on PCB | Applied over copper traces, except pads | Printed on top of solder mask or PCB surface |

| Color Options | Green, red, blue, black, white, etc. | Usually white or yellow for contrast |

| Thickness | Typically 15-35 microns | Very thin layer, less than 5 microns |

| Functionality | Electrical insulation and mechanical protection | Visual component identification and assembly aid |

| Durability | Highly durable against soldering heat and chemicals | Less durable, may fade or wear over time |

| Application Method | Screen printing or spray coating | Silkscreen printing or inkjet printing |

Introduction to Solder Mask and Legend Ink

Solder mask is a protective layer applied to printed circuit boards (PCBs) to prevent solder bridges and corrosion, ensuring electrical insulation and durability. Legend ink, also known as silkscreen, provides component identification and reference markings on the PCB surface for assembly and troubleshooting. Both materials use specialized formulations tailored for PCB manufacturing and must withstand the heat of the soldering process.

What is Solder Mask?

Solder mask is a protective layer applied to printed circuit boards (PCBs) to prevent solder bridges and short circuits during assembly by insulating copper traces and pads not meant for soldering. It typically has a polymer coating that resists heat and chemicals, ensuring durability and reliability in electronic components. Your PCB's functionality and defect prevention heavily depend on the quality and precision of the solder mask application.

What is Legend Ink?

Legend ink, also known as silkscreen ink, is used in printed circuit boards (PCBs) to print component outlines, reference designators, and other markings on the solder mask layer for easy identification during assembly and troubleshooting. This ink aids in visual clarity by providing contrast between the components and the board, enhancing inspection and repair processes. Unlike solder mask, which protects the board's copper traces from oxidation and solder bridging, legend ink serves an informational purpose without affecting electrical insulation.

Key Functions: Solder Mask vs Legend Ink

Solder mask serves as a protective layer on printed circuit boards (PCBs), preventing solder bridges and short circuits by insulating copper traces during soldering. Legend ink, also known as silkscreen, provides essential labeling, including component designators, logos, and reference marks, enhancing PCB readability and assembly accuracy. Both materials contribute to PCB functionality, with solder mask focusing on electrical protection and legend ink emphasizing visual identification.

Material Composition and Properties

Solder mask is typically made from epoxy-based or liquid photoimageable materials that provide excellent insulation, chemical resistance, and durability to protect PCB surfaces from oxidation and prevent solder bridging during assembly. Legend ink, also known as silkscreen ink, consists of epoxy or acrylic resins designed for high adhesion, UV resistance, and clear visibility to provide precise component identification and markings on the PCB. Understanding the distinct material compositions and properties of solder mask and legend ink helps ensure your PCB's performance and longevity in various environmental conditions.

Application Processes Compared

Solder mask is applied through a photoimageable process involving UV light exposure and chemical development to create precise protective coatings on PCB surfaces, whereas legend ink uses screen printing or inkjet techniques to add identification markings. Solder mask application requires careful curing to withstand soldering temperatures, providing insulation and preventing solder bridging, while legend ink must adhere well to withstand mechanical abrasion and chemical exposure during PCB assembly. The processes differ significantly in complexity, with solder mask demanding more controlled environmental conditions and curing steps compared to the relatively straightforward ink printing methods for legend text.

Impact on PCB Performance and Reliability

Solder mask provides essential protection by preventing solder bridges and corrosion, enhancing PCB performance and long-term reliability. Legend ink, while primarily used for component identification, contributes to traceability without directly affecting electrical performance. Your PCB's durability depends more on the solder mask's quality, as it safeguards the board from environmental damage and improves solder joint integrity.

Differences in Color and Appearance

Solder mask is typically green, although it comes in various colors such as red, blue, black, and white, providing the primary protective coating on a PCB and defining the areas where solder should not adhere. Legend ink, also called silkscreen, is usually white or yellow but can be printed in different colors to display component labels, logos, and markings on the PCB surface for assembly and identification. Your choice of solder mask and legend ink colors affects both the visual contrast and readability of the PCB, impacting inspection and repair efficiency.

Common Issues and Troubleshooting

Solder mask and legend ink are crucial for PCB functionality but can present common issues such as peeling, smearing, or misregistration due to improper curing or contamination during application. Troubleshooting these problems involves ensuring precise temperature control, using compatible materials, and maintaining a clean environment to prevent defects that can affect solderability and readability. You can enhance PCB quality by regularly inspecting adhesion and alignment, optimizing curing times, and selecting high-quality inks and masks suited for your manufacturing process.

Choosing Between Solder Mask and Legend Ink

Choosing between solder mask and legend ink depends on your PCB requirements, as solder mask provides essential insulation and protection against oxidation while preventing solder bridges, whereas legend ink offers visual identification for component placement and circuit tracing. Your decision should prioritize functionality; solder mask enhances electrical performance and durability, while legend ink improves assembly accuracy and maintenance. Understanding the specific role of each helps optimize your PCB's reliability and usability in complex electronic designs.

Solder mask vs Legend ink Infographic

electrown.com

electrown.com