E-beam evaporation offers greater precision and higher deposition rates compared to thermal evaporation, making it ideal for coating materials with high melting points. Explore the rest of the article to understand which method best suits your thin-film application needs.

Table of Comparison

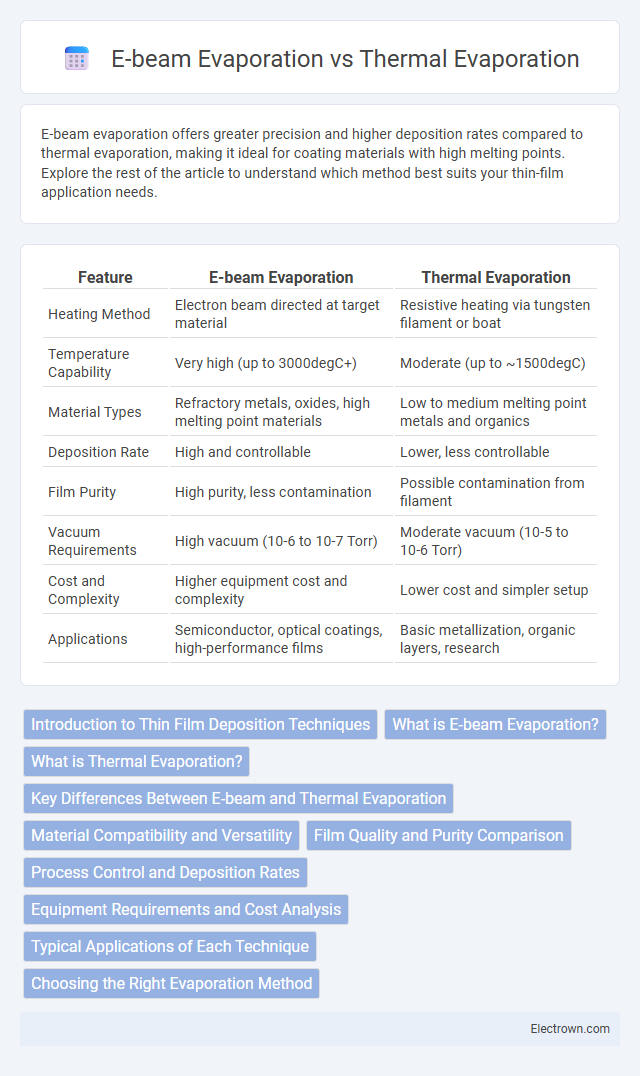

| Feature | E-beam Evaporation | Thermal Evaporation |

|---|---|---|

| Heating Method | Electron beam directed at target material | Resistive heating via tungsten filament or boat |

| Temperature Capability | Very high (up to 3000degC+) | Moderate (up to ~1500degC) |

| Material Types | Refractory metals, oxides, high melting point materials | Low to medium melting point metals and organics |

| Deposition Rate | High and controllable | Lower, less controllable |

| Film Purity | High purity, less contamination | Possible contamination from filament |

| Vacuum Requirements | High vacuum (10-6 to 10-7 Torr) | Moderate vacuum (10-5 to 10-6 Torr) |

| Cost and Complexity | Higher equipment cost and complexity | Lower cost and simpler setup |

| Applications | Semiconductor, optical coatings, high-performance films | Basic metallization, organic layers, research |

Introduction to Thin Film Deposition Techniques

E-beam evaporation offers precise control and high-purity thin film deposition by using an electron beam to vaporize the source material, making it ideal for complex and high-melting-point materials. Thermal evaporation relies on resistive heating to evaporate materials, providing a simpler and cost-effective method but with less precision and potential contamination from the heating element. Your choice between these techniques depends on the material properties and the desired film quality in semiconductor, optical, or coating applications.

What is E-beam Evaporation?

E-beam evaporation is a physical vapor deposition technique that uses an electron beam to heat and evaporate a target material in a high vacuum environment, enabling precise thin film deposition. This method provides higher purity films and better control over deposition rates compared to thermal evaporation, which relies on resistive heating of the source material. Your choice of E-beam evaporation can enhance film uniformity and reduce contamination, crucial for advanced semiconductor and optical coating applications.

What is Thermal Evaporation?

Thermal evaporation is a physical vapor deposition technique where a material is heated in a vacuum until it melts and evaporates, allowing it to condense onto a substrate as a thin film. This method is widely used for depositing metals, organic compounds, and dielectrics with high purity and controlled thickness. You benefit from thermal evaporation's cost-effectiveness and simplicity, despite its lower energy efficiency compared to E-beam evaporation.

Key Differences Between E-beam and Thermal Evaporation

E-beam evaporation utilizes a focused electron beam to heat and evaporate target materials with high precision and efficiency, enabling the deposition of high melting point metals and complex alloys. Thermal evaporation relies on resistive heating of a filament to vaporize materials, making it suitable for lower melting point substances but less efficient for refractory metals. E-beam evaporation generally offers better control over deposition rates, film uniformity, and purity compared to thermal evaporation.

Material Compatibility and Versatility

E-beam evaporation offers superior material compatibility by efficiently evaporating high melting point materials such as refractory metals and oxides, which are challenging for thermal evaporation. Thermal evaporation excels in versatility when processing low melting point materials like organic compounds and simple metals due to its straightforward heating method. Your choice depends on the specific material's melting point and chemical stability, making e-beam evaporation ideal for complex, high-performance coatings while thermal evaporation suits simpler, lower temperature applications.

Film Quality and Purity Comparison

E-beam evaporation produces higher film purity and superior density due to its high energy electron beam targeting the source material, which minimizes contamination and allows precise control over the deposition rate. Thermal evaporation operates at lower temperatures with resistance heating, often resulting in films with higher contamination and less uniformity due to limited control over material evaporation and potential outgassing. Consequently, E-beam evaporation is preferred for high-quality, pure thin films used in advanced semiconductor and optical applications.

Process Control and Deposition Rates

E-beam evaporation offers superior process control through precise electron beam targeting and adjustable power settings, enabling accurate material evaporation and uniform thin film deposition. Deposition rates in E-beam evaporation are typically higher, ranging from 10 to 100 nm/min, due to efficient heating of refractory materials. Thermal evaporation provides simpler control mechanisms but generally delivers lower deposition rates, often limited to 1 to 10 nm/min, impacting throughput in high-volume production.

Equipment Requirements and Cost Analysis

E-beam evaporation requires a high-vacuum chamber equipped with an electron beam gun capable of generating focused electron energy to vaporize materials, leading to higher initial equipment costs compared to thermal evaporation systems that use resistive heating coils in simpler vacuum chambers. The sophisticated control systems and maintenance needs of e-beam evaporators contribute to ongoing operational expenses, while thermal evaporators benefit from lower power consumption and less complex hardware, making them more cost-effective for basic thin-film deposition. Material compatibility and deposition rates also influence equipment lifecycle costs, with e-beam evaporation supporting a wider range of high-melting-point materials at higher deposition precision, justifying its higher investment for advanced applications.

Typical Applications of Each Technique

E-beam evaporation is commonly used for depositing high-melting-point materials like metals, oxides, and nitrides in applications such as semiconductor device fabrication, optical coatings, and thin-film solar cells. Thermal evaporation typically suits low-melting-point materials, making it ideal for metallization layers, organic electronics, and decorative coatings. Your choice depends on material compatibility and desired film properties for specific industrial or research applications.

Choosing the Right Evaporation Method

Choosing the right evaporation method depends on the material properties and desired film characteristics. E-beam evaporation provides high purity and precise control for high-melting-point materials, while thermal evaporation is cost-effective for low-melting-point materials with moderate deposition rates. Your specific application requirements, such as film uniformity and deposition rate, will determine the most suitable technique.

E-beam evaporation vs Thermal evaporation Infographic

electrown.com

electrown.com