Sputtering and evaporation are two common physical vapor deposition techniques used to create thin films by depositing material onto a substrate; sputtering utilizes ionized gas to eject atoms from a target, while evaporation relies on heating the source material until it vaporizes. Discover how these methods impact film quality and application to choose the best one for your next project.

Table of Comparison

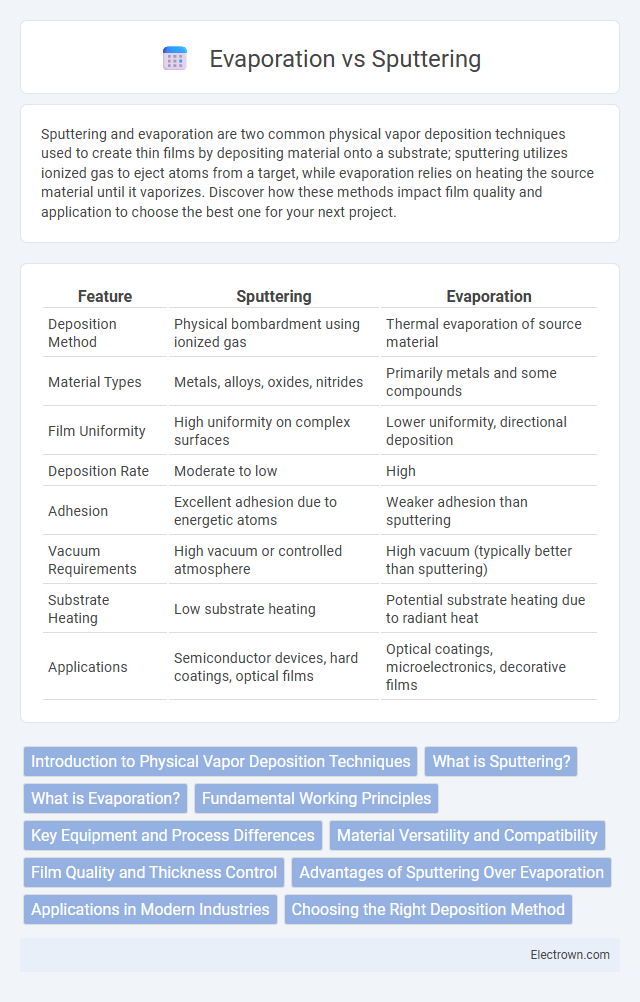

| Feature | Sputtering | Evaporation |

|---|---|---|

| Deposition Method | Physical bombardment using ionized gas | Thermal evaporation of source material |

| Material Types | Metals, alloys, oxides, nitrides | Primarily metals and some compounds |

| Film Uniformity | High uniformity on complex surfaces | Lower uniformity, directional deposition |

| Deposition Rate | Moderate to low | High |

| Adhesion | Excellent adhesion due to energetic atoms | Weaker adhesion than sputtering |

| Vacuum Requirements | High vacuum or controlled atmosphere | High vacuum (typically better than sputtering) |

| Substrate Heating | Low substrate heating | Potential substrate heating due to radiant heat |

| Applications | Semiconductor devices, hard coatings, optical films | Optical coatings, microelectronics, decorative films |

Introduction to Physical Vapor Deposition Techniques

Physical Vapor Deposition (PVD) techniques like sputtering and evaporation are essential for creating thin films in various industries. Sputtering uses ionized gas to eject material from a target, producing a uniform thin layer with excellent adhesion and coverage on complex surfaces. Evaporation relies on heating the source material until it vaporizes, allowing you to achieve high deposition rates but with limited control over film uniformity.

What is Sputtering?

Sputtering is a physical vapor deposition (PVD) technique where ions from a plasma collide with a target material, causing atoms to be ejected and deposited onto a substrate. This process offers precise control over film thickness and composition, making it ideal for producing thin films in semiconductor manufacturing, optics, and coating industries. Your devices benefit from sputtering's uniform and adherent coatings, enhancing performance and durability.

What is Evaporation?

Evaporation is a physical vapor deposition (PVD) technique where material is heated in a vacuum chamber until it vaporizes and condenses as a thin film on a substrate. This method offers high deposition rates and is suitable for materials with low melting points, though it often results in less uniform coatings compared to sputtering. Understanding evaporation helps optimize thin film applications in industries like semiconductor manufacturing and optics, ensuring precise control over film thickness and composition for your specific needs.

Fundamental Working Principles

Sputtering operates by bombarding a target material with high-energy ions, causing atoms to be ejected and deposited onto a substrate, enabling precise thin-film coatings. Evaporation involves heating a source material until it vaporizes, then condenses as a thin film on the substrate under vacuum conditions, offering high deposition rates and material purity. Your choice between sputtering and evaporation depends on factors like film adhesion, layer uniformity, and application-specific requirements.

Key Equipment and Process Differences

Sputtering uses a plasma source and a target material bombarded by ions to eject atoms, while evaporation involves heating a source material until it vaporizes and deposits onto a substrate. Key equipment for sputtering includes a vacuum chamber with a magnetron sputter gun, whereas evaporation requires a thermal or electron beam evaporator. Your choice depends on film uniformity, adhesion, and material compatibility, as sputtering offers better control over film composition and density compared to evaporation.

Material Versatility and Compatibility

Sputtering offers greater material versatility and compatibility by enabling the deposition of a wide range of metals, alloys, oxides, and nitrides with excellent film adhesion and uniformity, making it suitable for complex substrates and multilayer structures. Evaporation, while capable of producing high-purity films, is generally limited to materials with relatively low melting points and may face challenges with alloys and compounds due to differential evaporation rates. Choosing sputtering enhances your ability to tailor thin films for diverse applications requiring precise control over composition and thickness across various materials.

Film Quality and Thickness Control

Sputtering offers superior film quality with denser and more uniform coatings due to its energetic particle deposition process, enhancing adhesion and reducing defects. Thickness control in sputtering is precise, enabling uniform thin films even on complex substrates, while evaporation may struggle with uniformity and consistent thickness on non-flat surfaces. Your choice depends on the need for high-quality films and exact thickness control, where sputtering generally provides better performance.

Advantages of Sputtering Over Evaporation

Sputtering offers superior film adhesion and uniformity compared to evaporation, making it ideal for coating complex surfaces and large areas consistently. It allows precise control over film thickness and composition, enabling high-quality thin films with enhanced durability and performance. Your applications benefit from sputtering's ability to deposit alloys and compounds with minimal contamination and improved step coverage.

Applications in Modern Industries

Sputtering and evaporation are widely utilized thin film deposition techniques essential in semiconductor manufacturing, enabling the production of microchips and integrated circuits with high precision. Sputtering is preferred in applications requiring uniform coatings on complex surfaces, such as in the fabrication of magnetic storage devices and optical coatings. Evaporation is commonly applied in solar cell production and decorative metal coatings due to its high deposition rates and ability to produce pure films.

Choosing the Right Deposition Method

Choosing the right deposition method depends on your specific application requirements, including film uniformity, adhesion, and material properties. Sputtering offers better step coverage and adheres well to various substrates, making it ideal for complex geometries, while evaporation provides higher deposition rates and cost-efficiency for simpler, line-of-sight coatings. Evaluating factors like target material compatibility, vacuum system capability, and desired film thickness will help optimize your thin film deposition process.

Sputtering vs Evaporation Infographic

electrown.com

electrown.com