Pneumatic transmitters convert process variables into standardized air pressure signals, offering robust performance in hazardous environments without electrical power, while electronic transmitters provide higher accuracy, faster response times, and compatibility with digital control systems. Explore the rest of this article to understand which transmitter best suits your industrial application and operational needs.

Table of Comparison

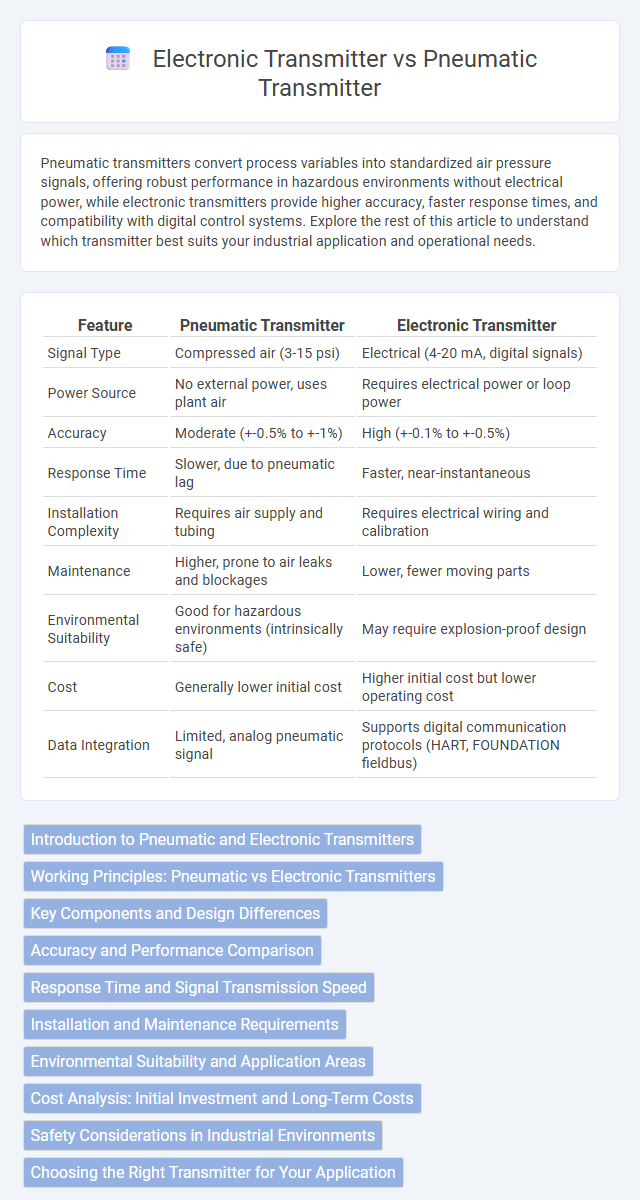

| Feature | Pneumatic Transmitter | Electronic Transmitter |

|---|---|---|

| Signal Type | Compressed air (3-15 psi) | Electrical (4-20 mA, digital signals) |

| Power Source | No external power, uses plant air | Requires electrical power or loop power |

| Accuracy | Moderate (+-0.5% to +-1%) | High (+-0.1% to +-0.5%) |

| Response Time | Slower, due to pneumatic lag | Faster, near-instantaneous |

| Installation Complexity | Requires air supply and tubing | Requires electrical wiring and calibration |

| Maintenance | Higher, prone to air leaks and blockages | Lower, fewer moving parts |

| Environmental Suitability | Good for hazardous environments (intrinsically safe) | May require explosion-proof design |

| Cost | Generally lower initial cost | Higher initial cost but lower operating cost |

| Data Integration | Limited, analog pneumatic signal | Supports digital communication protocols (HART, FOUNDATION fieldbus) |

Introduction to Pneumatic and Electronic Transmitters

Pneumatic transmitters operate by converting process variables into a proportional air pressure signal, typically 3-15 psi, using mechanical components and compressed air, ideal for hazardous environments due to their intrinsic safety. Electronic transmitters convert process measurements into standardized electrical signals, such as 4-20 mA or HART protocols, offering higher accuracy, faster response, and advanced diagnostics for complex industrial automation systems. Both transmitter types play crucial roles in process control, with pneumatic transmitters favored in older or explosion-prone settings and electronic transmitters prevalent in modern, digitally integrated plants.

Working Principles: Pneumatic vs Electronic Transmitters

Pneumatic transmitters operate by converting process variables into a pneumatic signal, typically using pressure changes to transmit data through compressed air, making them ideal for environments lacking electricity. Electronic transmitters use sensors such as strain gauges or capacitive elements to convert physical measurements into electrical signals, offering higher accuracy and faster response times. Your choice between pneumatic and electronic transmitters depends on factors like power availability, required precision, and environmental conditions.

Key Components and Design Differences

Pneumatic transmitters rely on components such as flapper-nozzle systems and baffles to convert process variables into air pressure signals, whereas electronic transmitters use sensors, microprocessors, and signal conditioning circuits for precise electrical output. The design of pneumatic transmitters is inherently simple and robust, suitable for explosive or high-temperature environments, while electronic transmitters offer higher accuracy, faster response times, and easier integration with digital control systems. Your choice depends on system requirements, with electronic transmitters excelling in complex automation and pneumatic transmitters preferred for hazardous or intrinsically safe applications.

Accuracy and Performance Comparison

Pneumatic transmitters typically offer moderate accuracy with response times suitable for less demanding industrial processes, often achieving +-0.25% to +-0.5% of span. Electronic transmitters deliver higher precision and faster response rates, commonly reaching accuracies of +-0.05% to +-0.1% of span due to advanced sensor technology and digital signal processing. Performance-wise, electronic transmitters provide enhanced stability, lower signal drift, and better integration with modern control systems compared to the inherently slower and pressure-dependent pneumatic units.

Response Time and Signal Transmission Speed

Pneumatic transmitters generally have slower response times and signal transmission speeds due to the compressibility of air and mechanical components involved, resulting in delays typically ranging from 200 to 500 milliseconds. Electronic transmitters offer significantly faster response times, often in the range of 10 to 50 milliseconds, by using electronic sensors and digital signals that enable real-time data processing and transmission. Faster signal transmission in electronic transmitters enhances process control accuracy and responsiveness, making them preferable for applications requiring high-speed monitoring.

Installation and Maintenance Requirements

Pneumatic transmitters require compressed air supply and often need regular calibration and maintenance of pneumatic lines to prevent leaks and ensure accuracy. Electronic transmitters generally offer easier installation with fewer mechanical parts, reducing maintenance frequency and allowing for remote diagnostics and calibration. Maintenance of electronic transmitters primarily involves software updates and occasional sensor checks, making them more efficient for long-term operation.

Environmental Suitability and Application Areas

Pneumatic transmitters excel in hazardous environments where intrinsic safety is critical, such as oil refineries and chemical plants, due to their resistance to electrical sparks and ability to operate without a power source. Electronic transmitters offer higher accuracy and faster response times, making them ideal for applications requiring precise measurements in modern industries like pharmaceuticals and semiconductor manufacturing. Your choice depends on environmental conditions and the required measurement precision for optimal process performance.

Cost Analysis: Initial Investment and Long-Term Costs

Pneumatic transmitters typically have a lower initial investment cost compared to electronic transmitters, making them suitable for applications with budget constraints. However, electronic transmitters offer greater accuracy and reliability, reducing maintenance and calibration expenses over time, which can lead to lower long-term operational costs. When evaluating total cost of ownership, electronic transmitters often provide better return on investment despite higher upfront costs due to enhanced performance and reduced downtime.

Safety Considerations in Industrial Environments

Pneumatic transmitters offer inherent safety advantages in hazardous industrial environments by eliminating electrical sparks and reducing ignition risks, making them suitable for explosive atmospheres. Electronic transmitters require intrinsic safety measures such as explosion-proof enclosures or intrinsically safe barriers to prevent electrical hazards in volatile settings. Proper selection between pneumatic and electronic transmitters depends on the facility's safety standards, environmental conditions, and compliance with industry regulations like NEC and ATEX.

Choosing the Right Transmitter for Your Application

Pneumatic transmitters offer reliable performance in hazardous or explosive environments due to their intrinsic safety and resistance to electrical interference, making them ideal for chemical plants and oil refineries. Electronic transmitters provide higher accuracy, faster response times, and easier integration with modern digital control systems, suitable for applications requiring precise measurement and advanced diagnostics. Evaluating your process requirements, environmental conditions, and communication needs ensures selecting the right transmitter optimizes system efficiency and reliability.

pneumatic transmitter vs electronic transmitter Infographic

electrown.com

electrown.com