Nanocantilever sensors detect minute mass changes through mechanical deflections, offering ultra-sensitive chemical and biological detection, while nanowire sensors rely on changes in electrical conductivity for highly responsive and selective analyte detection. Discover how these nanoscale technologies differ in performance and applications to choose the best sensor for your needs.

Table of Comparison

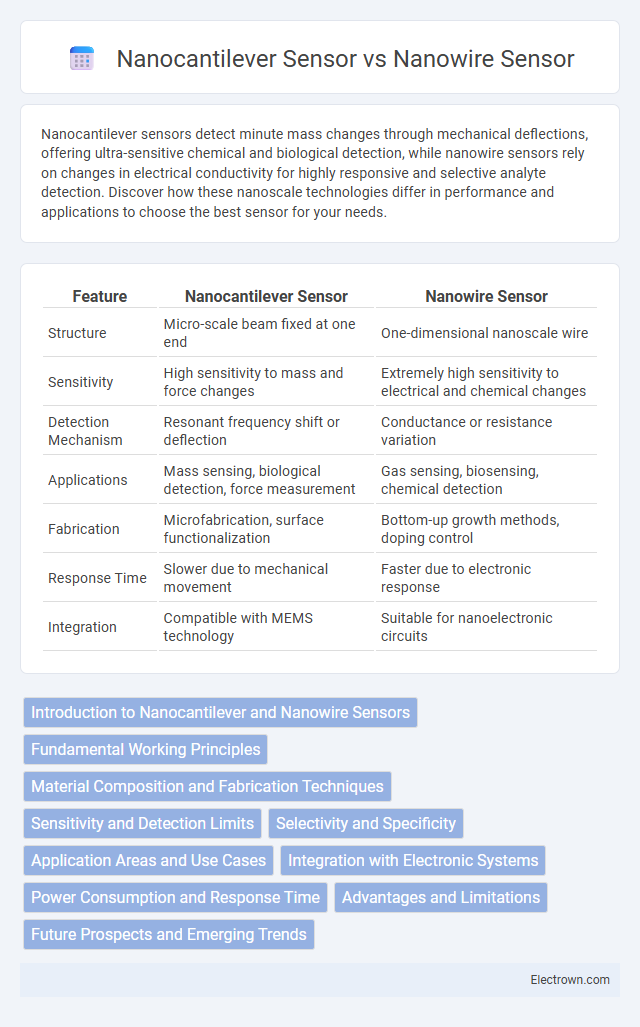

| Feature | Nanocantilever Sensor | Nanowire Sensor |

|---|---|---|

| Structure | Micro-scale beam fixed at one end | One-dimensional nanoscale wire |

| Sensitivity | High sensitivity to mass and force changes | Extremely high sensitivity to electrical and chemical changes |

| Detection Mechanism | Resonant frequency shift or deflection | Conductance or resistance variation |

| Applications | Mass sensing, biological detection, force measurement | Gas sensing, biosensing, chemical detection |

| Fabrication | Microfabrication, surface functionalization | Bottom-up growth methods, doping control |

| Response Time | Slower due to mechanical movement | Faster due to electronic response |

| Integration | Compatible with MEMS technology | Suitable for nanoelectronic circuits |

Introduction to Nanocantilever and Nanowire Sensors

Nanocantilever sensors operate by detecting mechanical deflections caused by molecular interactions on their surfaces, leveraging microfabricated beams that respond to minute forces with high sensitivity. Nanowire sensors utilize one-dimensional semiconductor or metal wires whose electrical properties, such as conductivity, change upon exposure to target analytes, enabling rapid and label-free detection. Both sensors play pivotal roles in nanoscale sensing applications, with nanocantilevers excelling in mass and force detection, while nanowires offer enhanced electrical signal transduction for chemical and biological sensing.

Fundamental Working Principles

Nanocantilever sensors operate by detecting changes in resonance frequency or deflection caused by surface stress variations when analytes bind to their functionalized surfaces. Nanowire sensors rely on changes in electrical conductivity or carrier concentration within the nanowire material when molecules adsorb or react on its surface. Both sensor types leverage nanoscale dimensions to achieve high sensitivity, with nanocantilevers translating mechanical property shifts into signals and nanowires converting chemical interactions into electrical responses.

Material Composition and Fabrication Techniques

Nanocantilever sensors typically utilize silicon, silicon nitride, or piezoelectric materials, fabricated via top-down lithography and etching techniques to achieve precise dimensions and high sensitivity. Nanowire sensors often employ semiconductor materials like silicon, zinc oxide, or carbon-based compounds, produced through bottom-up approaches such as chemical vapor deposition (CVD) or vapor-liquid-solid (VLS) growth. The distinct fabrication methods influence the structural properties and sensing performance, enabling nanocantilevers for mechanical deflection detection and nanowires for electrical or optical signal transduction.

Sensitivity and Detection Limits

Nanocantilever sensors exhibit high sensitivity due to their mechanical resonance frequency shifts in response to minute mass changes, enabling detection limits down to the single-molecule level. Nanowire sensors provide exceptional electrical sensitivity by measuring conductance variations caused by surface charge changes, achieving detection limits in the femtomolar range for biomolecules. Both sensor types offer ultrasensitive detection capabilities, with nanocantilevers excelling in mass-based sensing and nanowires providing superior electrical signal transduction for chemical and biological analytes.

Selectivity and Specificity

Nanocantilever sensors exhibit high selectivity through surface functionalization that enables precise detection of specific molecules by changes in resonance frequency or deflection, making them ideal for detecting biomolecules and gases. Nanowire sensors offer exceptional specificity due to their high surface-to-volume ratio and electrical conductance changes upon target molecule binding, allowing for sensitive and selective detection at the single-molecule level. Both sensors provide distinct advantages in biochemical sensing, with nanocantilevers excelling in mechanical signal transduction and nanowires in electronic signal modulation for selective and specific analyte recognition.

Application Areas and Use Cases

Nanocantilever sensors excel in detecting biomolecular interactions and environmental pollutants, widely utilized in medical diagnostics and chemical sensing due to their high sensitivity to mass changes. Nanowire sensors are prominent in electronic and optical applications, serving as ultra-sensitive detectors for gases, biomolecules, and physical stimuli in healthcare monitoring and environmental analysis. Both sensor types enable nanoscale detection with distinct advantages: nanocantilevers for mechanical property changes and nanowires for electrical conductivity variations.

Integration with Electronic Systems

Nanocantilever sensors offer seamless integration with electronic systems due to their compatibility with microelectromechanical systems (MEMS) technology, enabling efficient signal transduction and miniaturization. Nanowire sensors, while highly sensitive, often require complex interfacing circuits to convert their electrical responses into usable signals, posing challenges for direct integration. Your choice between these sensors hinges on the desired balance between integration complexity and sensing performance in electronic device applications.

Power Consumption and Response Time

Nanocantilever sensors typically exhibit lower power consumption due to their mechanical deflection-based sensing mechanism, requiring minimal electrical input. Nanowire sensors often achieve faster response times because of their high surface-to-volume ratio, which enhances sensitivity and accelerates signal transduction. Power efficiency and response speed are critical factors determining the choice between nanocantilever and nanowire sensors in applications like environmental monitoring and biomedical diagnostics.

Advantages and Limitations

Nanocantilever sensors offer high sensitivity and label-free detection by measuring mechanical deflection caused by molecular interactions, making them ideal for detecting biomolecules and environmental toxins with rapid response times. Their limitations include susceptibility to noise from temperature fluctuations and complex surface functionalization processes. In contrast, nanowire sensors provide excellent electrical signal transduction with high surface-to-volume ratios, enabling ultra-sensitive detection of gases and biological markers; however, challenges include fabrication complexity and stability issues under varying environmental conditions.

Future Prospects and Emerging Trends

Nanocantilever sensors offer exceptional sensitivity for chemical and biological detection, leveraging mechanical deflection changes, while nanowire sensors provide enhanced electrical conductivity and integration with nanoelectronic systems. Future prospects emphasize hybrid devices combining nanocantilever mechanical responsiveness with nanowire electrical signal transduction, aiming to achieve ultrahigh sensitivity and selectivity in real-time diagnostics. Your choice may depend on the specific application requirements, with emerging trends focusing on scalable fabrication and multifunctional sensing platforms.

Nanocantilever Sensor vs Nanowire Sensor Infographic

electrown.com

electrown.com